Welding process of offshore wind power foundation steel pipe pile

An offshore wind power and welding process technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of deep low-compression bearing layer, cannot be directly used as bearing layer, and the upper fan has a large load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with accompanying drawing.

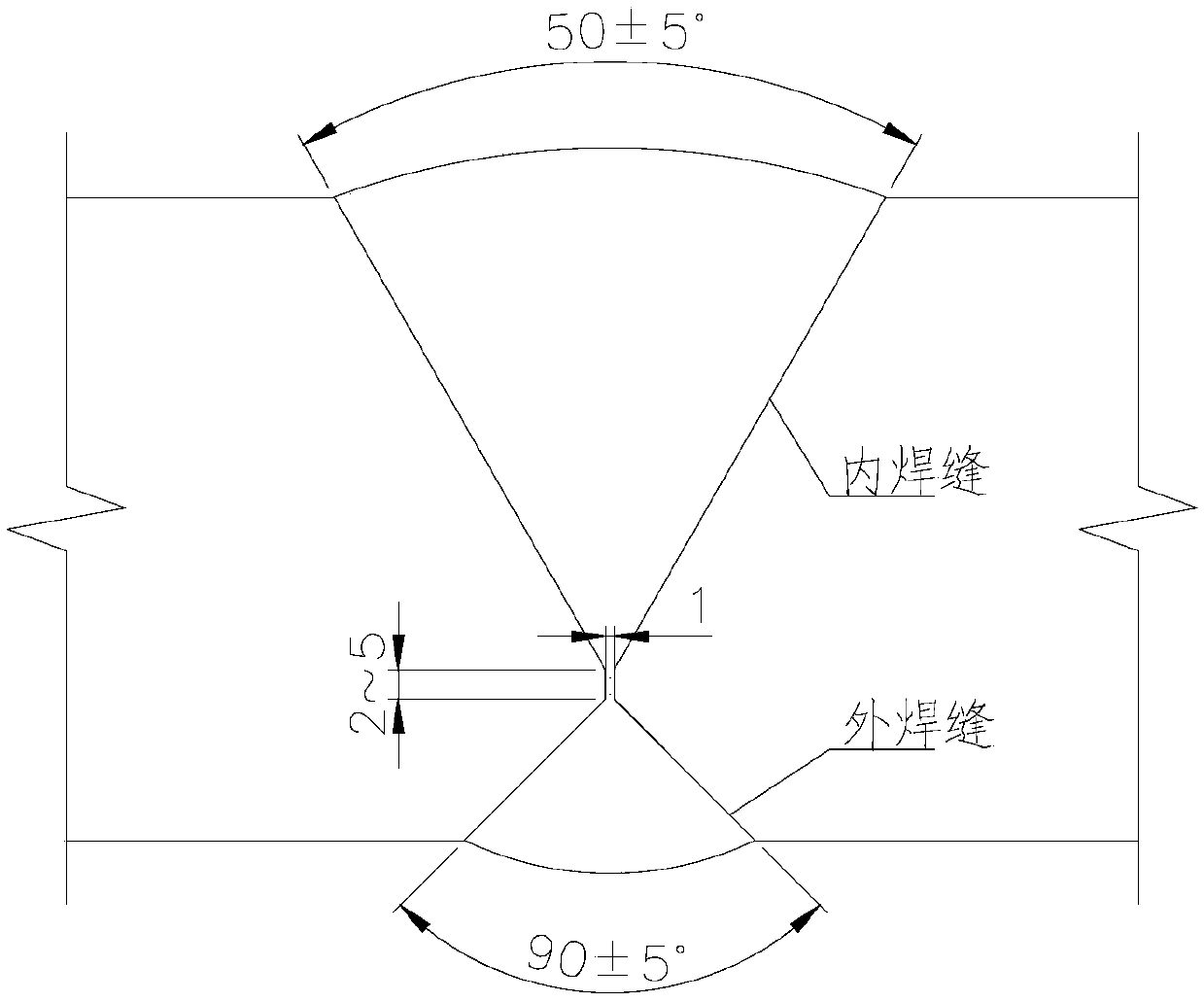

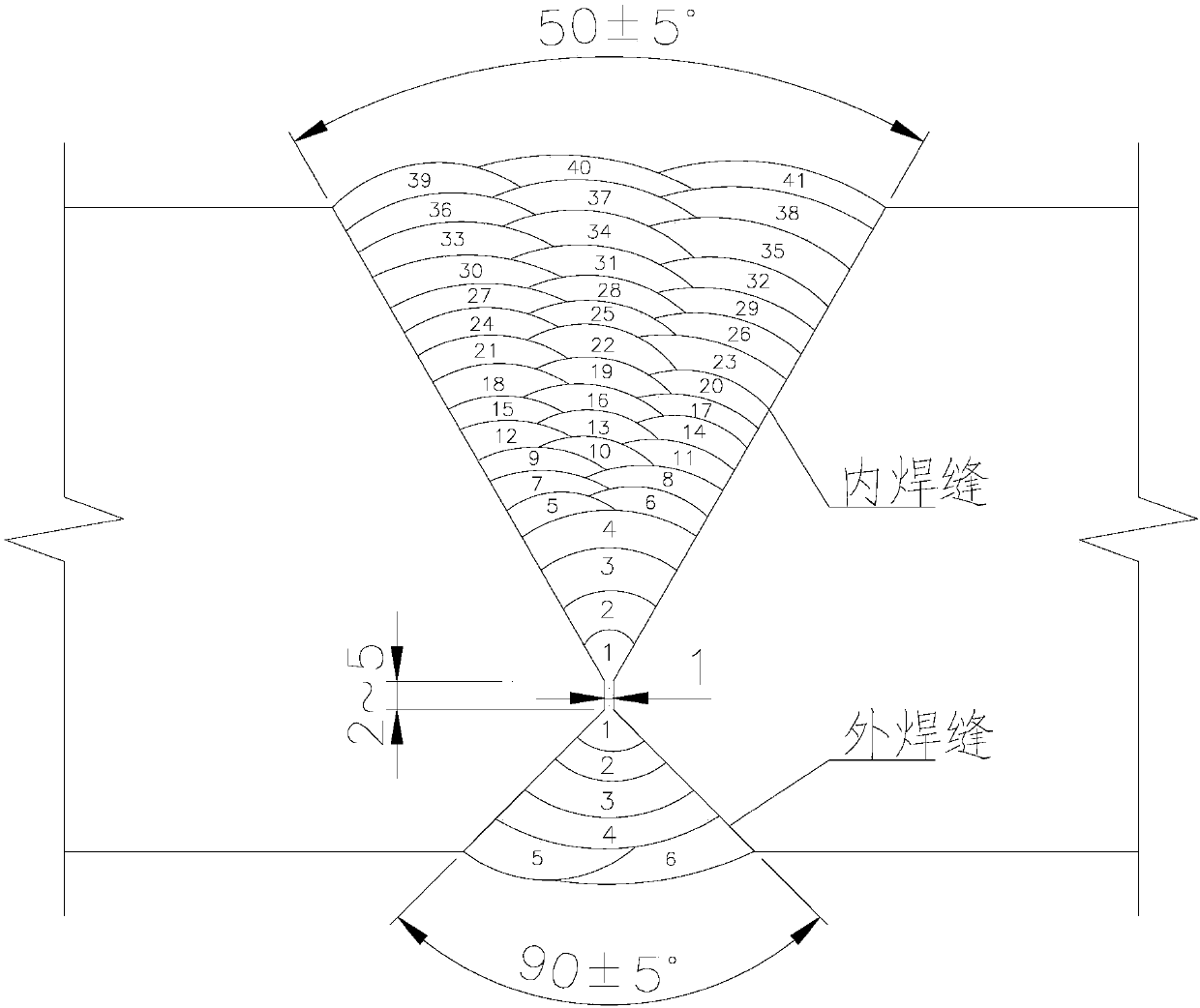

[0059] see figure 1 with figure 2 , the welding process of steel pipe piles for offshore wind power foundations of the present invention includes the following processes: opening a weld groove, steel plate butt joint longitudinal seam welding, coiled pipe longitudinal seam welding, 1+1 single pipe joint splicing circular seam welding, 2+2 Segmental splicing girth welding, flange and single pipe joint girth welding and whole pile splicing girth welding; when performing the weld beveling process, use a semi-automatic flame gas cutting machine to create an X-shaped weld bevel on the butt edge of the steel plate. The groove angle of the weld seam is α=50±5°, the groove depth of the inner weld seam is 2 / 3 of the thickness d of the steel plate, the blunt edge is 2~5mm, the root gap is 0~1mm, and the groove angle of the outer weld seam is β =90±5°(see figure 1 );

[0060] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com