Activated carbon screening device

A screening device and activated carbon technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of poor screening effect, loose joints, inconvenient use, etc., and achieve fast and efficient screening, convenient installation, and device The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

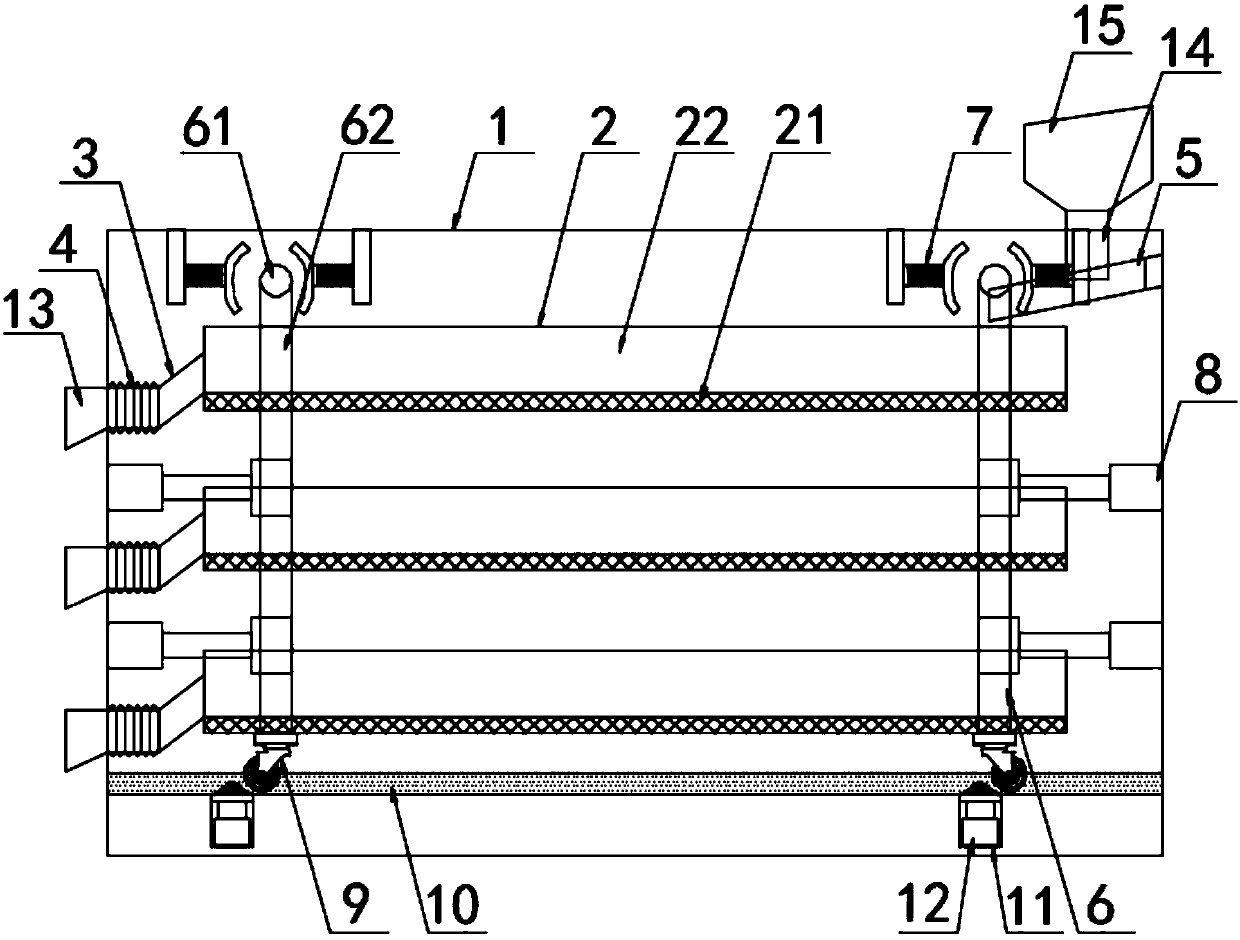

[0027] according to Figure 1-2 A kind of activated carbon screening device shown comprises a body 1, and the inside of the body 1 is provided with a multi-layer screening bucket 2, and the multi-layer screening bucket 2 is sequentially arranged from top to bottom, and the screening bucket 2 includes The mesh plate 21 and the surrounding plate 22, the surrounding plate 22 is arranged around the top edge of the mesh plate 21, and the mesh plate 21 is evenly provided with a plurality of mesh holes, and the mesh aperture corresponding to the multi-layer screening bucket 2 gradually decreases , for sieving activated carbon particles of different diameters, one end of the multi-layer screening bucket 2 is provided with a discharge hopper 3, and one side of the discharge hopper 3 is provided with an elastic lower material cover 4, and the elastic lower material cover 4. The outer wall is arranged in an organ shape, and the outer wall of the body 1 corresponding to one side of the el...

Embodiment 2

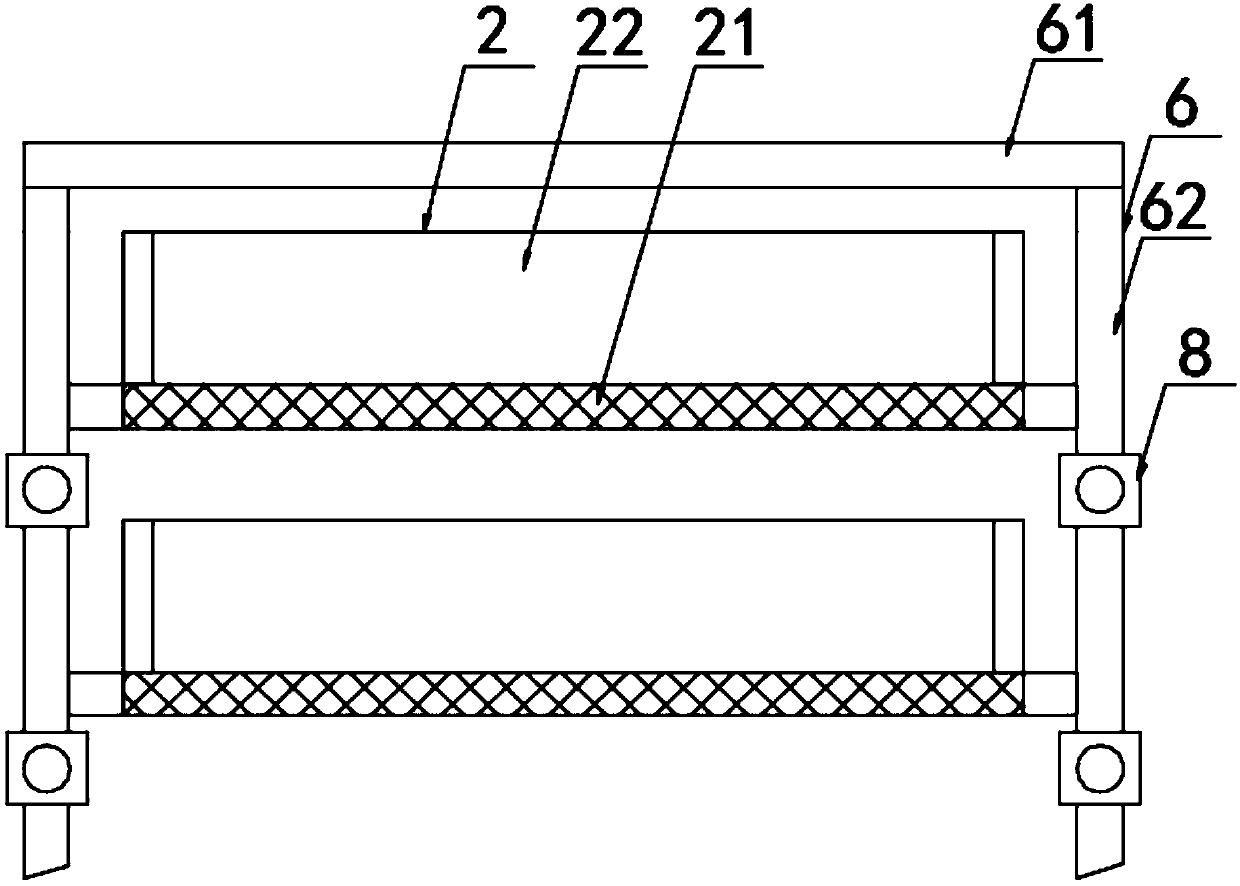

[0030] according to Figure 3-4 In the shown activated carbon screening device, the vertical rod 62 is fixedly arranged at the front and rear ends of the ejector rod 61, the mesh plate 21 is fixedly connected with the vertical rod 62 through a bracket, and the cross section of the ejector rod 61 is set to be circular. The section of the vertical bar 62 is set to be rectangular;

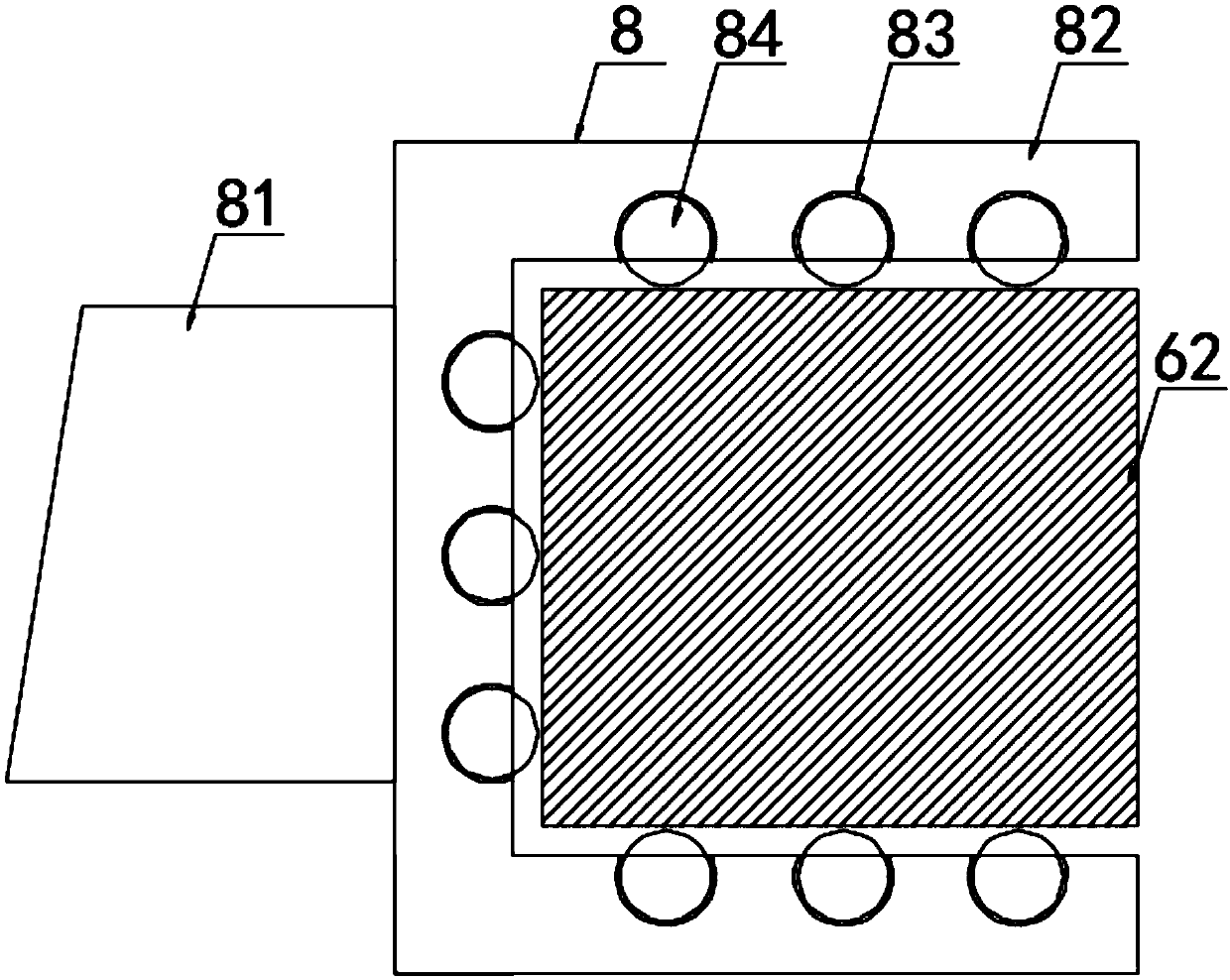

[0031] according to Figure 4In the shown activated carbon screening device, the buffer mechanism 7 includes a first buffer plate 71 and a second buffer plate 72, and the outside of the first buffer plate 71 and the second buffer plate 72 are provided with a sponge pad, so The outer sides of the first buffer plate 71 and the second buffer plate 72 are fixed with a spring 73, and one side of the spring 73 is fixed with a support plate 74, and the support plate 74 is fixedly connected with the body 1, and the push rod 61 is set Between the first buffer plate 71 and the second buffer plate 72, the sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com