A core removal device for apple juice pretreatment processing equipment

A processing equipment and pretreatment technology, which can be used in fruit de-pitting devices, food science, applications, etc., can solve the problem of high labor intensity, and achieve the effect of reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

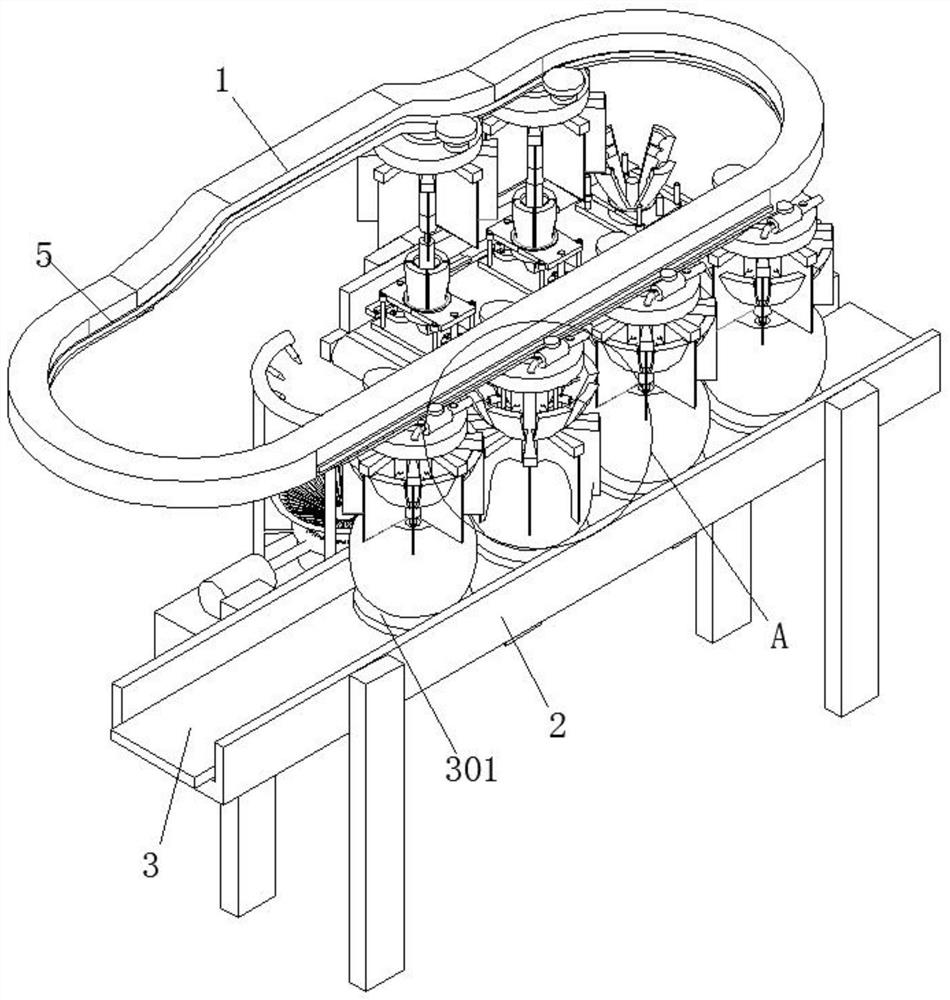

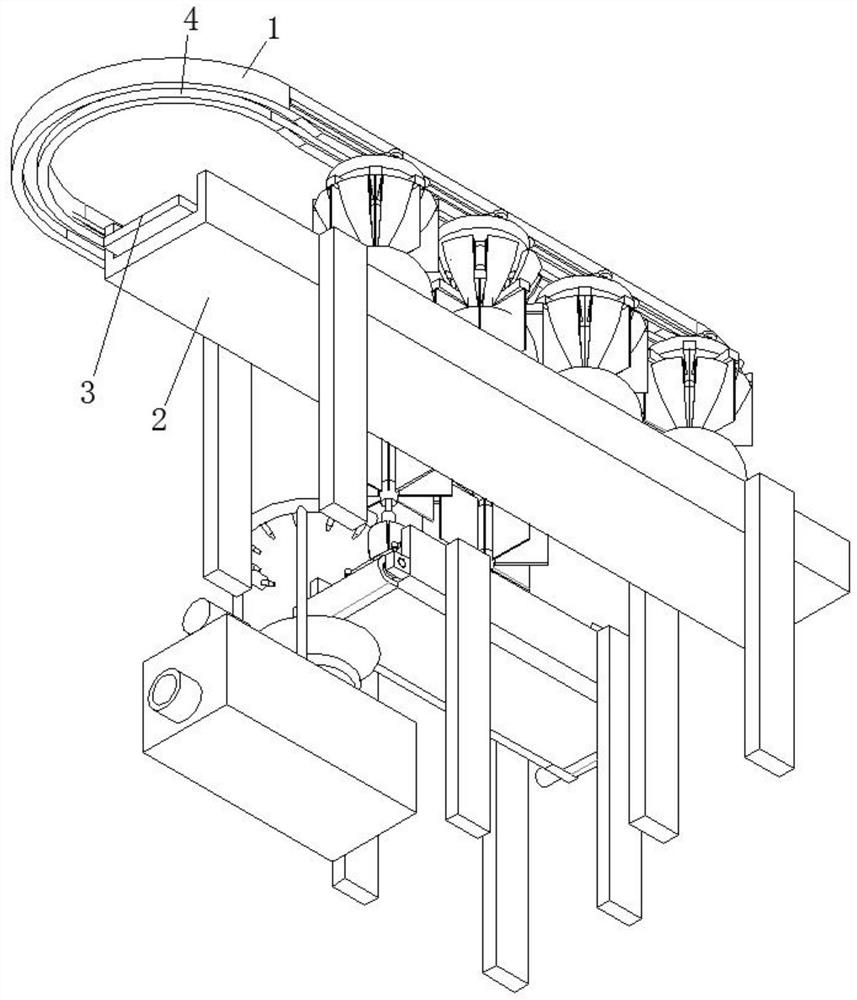

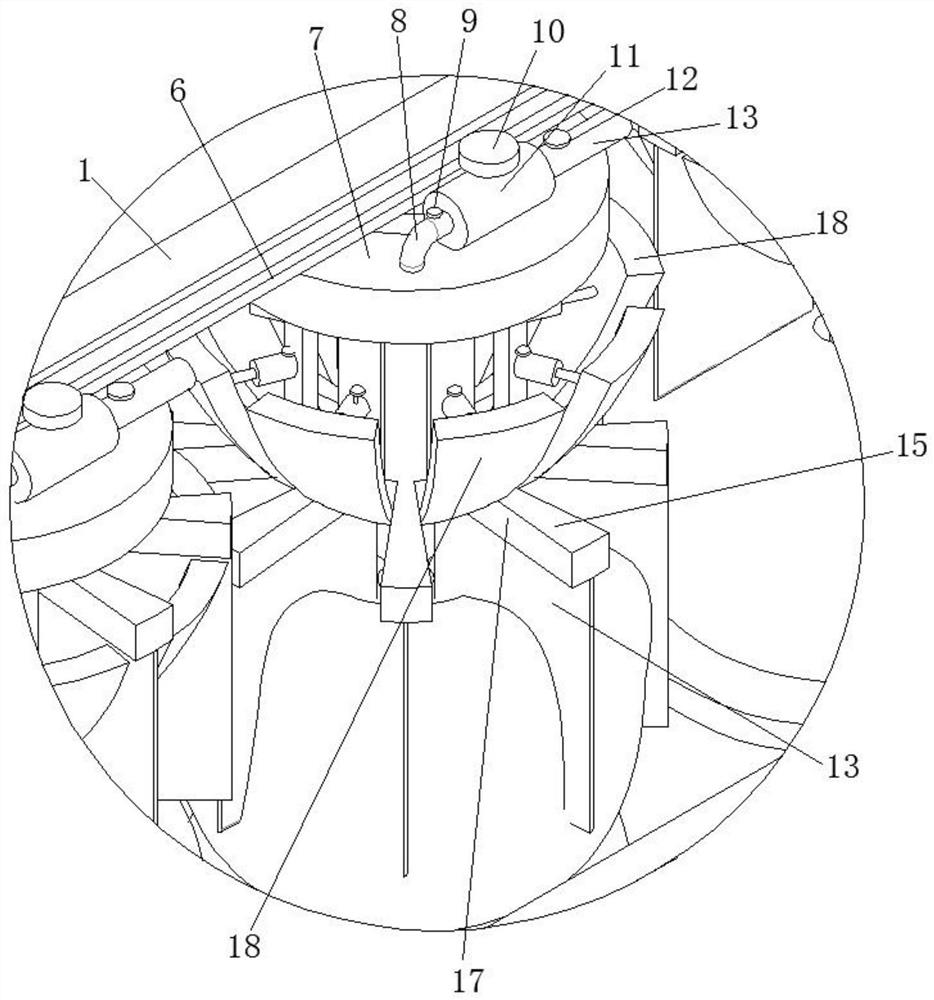

[0036] refer to Figure 1-14 , a cutting and separating device for apple juice pretreatment processing equipment, comprising a circulating ring plate 1 and a conveying plate 2, the circulating ring plate 1 is located above the conveying plate 2, and the bottom side of the circulating ring plate 1 is slidably connected with a supporting plate 19, and the supporting plate The bottom side of 19 is fixedly connected with the first electric telescopic rod 26, the bottom side of the first electric telescopic rod 26 is fixedly connected with the pin 23, the bottom side of the support plate 19 is fixedly connected with the second electric telescopic rod 25, and the lower end of the second electric telescopic rod 25 A connecting plate 15 is connected, the bottom side of the connecting plate 15 is connected with a cutting ring piece 24 and a split slice 16, the split slice 16 is connected with the cutting ring piece 24, and the cutting ring piece 24 is set on the first electric telescopi...

Embodiment 2

[0048] refer to Figure 1-10 , a cutting and separating device for apple juice pretreatment processing equipment, comprising a circulating ring plate 1 and a conveying plate 2, the circulating ring plate 1 is located above the conveying plate 2, and the bottom side of the circulating ring plate 1 is slidably connected with a supporting plate 19, and the supporting plate The bottom side of 19 is fixedly connected with the first electric telescopic rod 26, the bottom side of the first electric telescopic rod 26 is fixedly connected with the pin 23, the bottom side of the support plate 19 is fixedly connected with the second electric telescopic rod 25, and the lower end of the second electric telescopic rod 25 A connecting plate 15 is connected, the bottom side of the connecting plate 15 is connected with a cutting ring piece 24 and a split slice 16, the split slice 16 is connected with the cutting ring piece 24, and the cutting ring piece 24 is set on the first electric telescopi...

Embodiment 3

[0058] refer to Figure 1-10 , a cutting and separating device for apple juice pretreatment processing equipment, its structure is basically the same as that of Embodiment 2, further, the first connecting pipe 8 is connected with a first one-way valve 9, and the second connecting pipe 13 is connected with There is a second one-way valve 12, and the first one-way valve 9 and the second one-way valve 12 effectively prevent gas from flowing backward.

[0059] The lifting plate 1-16 is fixedly connected with a stabilizing cover 1-7, and the base plate 1-6 is fixedly connected with a stabilizing bar 1-8 corresponding to the stabilizing cover 1-7; Under the action, it can effectively ensure the stable movement of the lifting plate 1-16 up and down.

[0060] A clamping ring 1-11 is arranged on the inner side of the arc-shaped clamping plate 1-12, which facilitates further effective clamping of the apple core and facilitates clamping and removal.

[0061] The base plate 1-6 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com