Cylindricity non-contact measuring device and method for precision workpiece

A non-contact, measuring device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as large errors, workpiece damage, and small scratches on the surface, so as to eliminate measurement errors, avoid damage, and improve Measuring the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

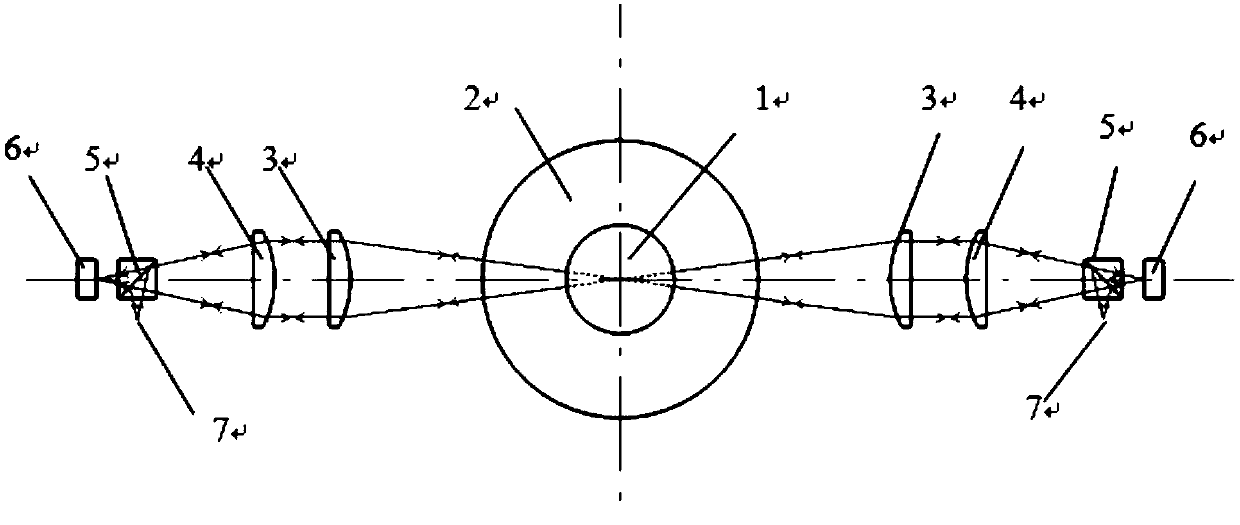

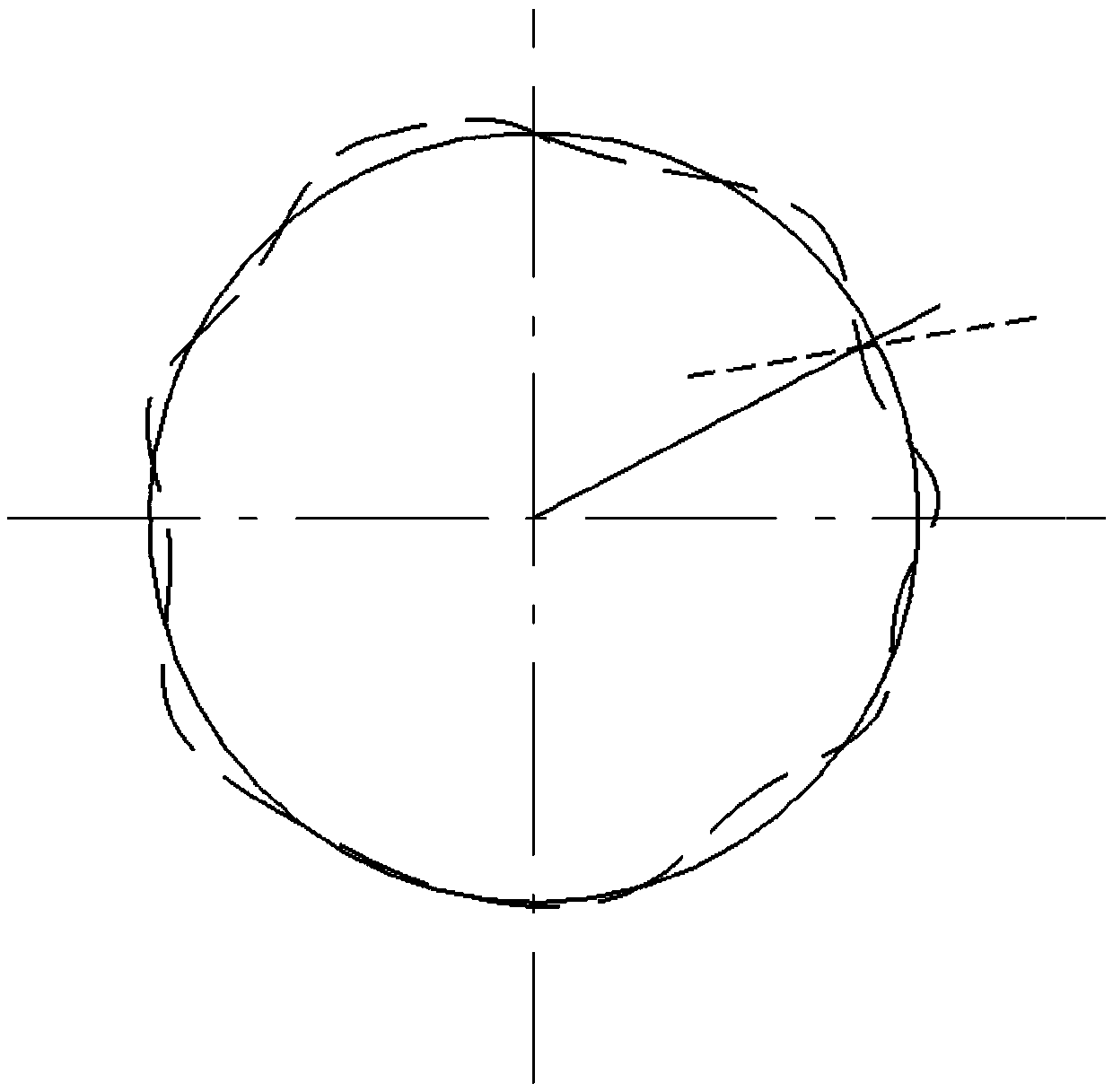

[0033] Such as figure 1 As shown, a non-contact measuring device for cylindricity of a precision workpiece includes a turntable 2 and two sets of cylindrical autocollimators arranged on the side of the turntable 2; the turntable 2 is used to fix the measured cylindrical workpiece 1, and the measured cylindrical The workpiece 1 is coaxial with the turntable 2, and each group of cylindrical autocollimators includes a line light source 7, and a standard cylindrical lens 3, a collimating cylindrical lens 4, a light splitting element 5, and a light sensor 6 are sequentially arranged from the inside to the outside of the turntable 2 The light beam sent by the line light source 7 passes through the light splitting element 5, and is reflected to the collimated cylindrical mirror 4, becomes a parallel light beam through the collimated cylindrical mirro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com