A centrifugal wind wheel and a low-noise backward centrifugal fan including the wind wheel

A centrifugal wind wheel and wind wheel technology, which is applied in the field of centrifugal wind wheel and low-noise backward centrifugal fan, can solve the problems of limited destructive effect and limited noise reduction effect, and achieve the goals of reducing turbulent flow intensity, low manufacturing cost, and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

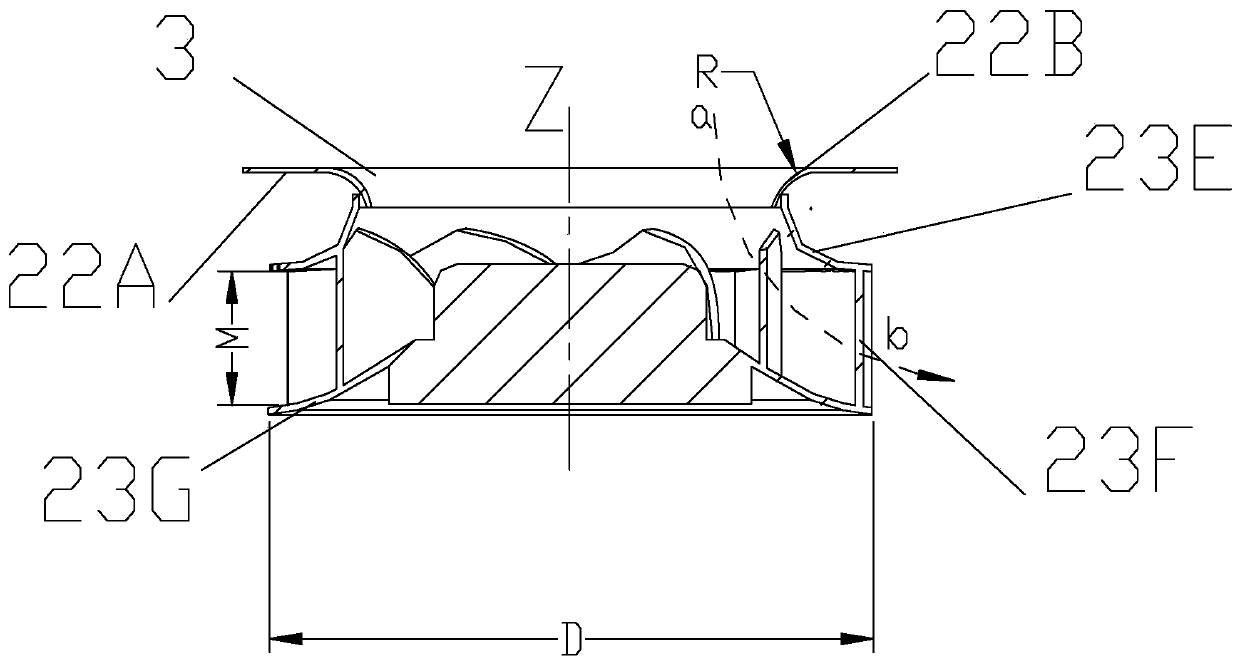

[0047] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. In this embodiment, the arc radii of each of the multi-section arc walls are different, and the arc radii of the multi-section arc walls increase sequentially along the direction from the air inlet end to the air outlet end. arranged in a manner. Preferably in this embodiment, the multiple sections of arc walls include two sections of arc walls. The multi-segment arc walls make the air flow enter the collector 3 and accelerate the gathering towards the end of the collector 3 .

Embodiment 3

[0049] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. In this embodiment, a vertical wall is provided at the end of the arc wall in the wind guide side wall 22B, the diameter of the vertical wall remains constant along the direction from the air inlet end to the air outlet end, and the inner diameter of the vertical wall The diameter of the ring is smaller than the diameter of the inner ring of the single-segment arc wall or any one of the multi-segment arc walls, and the continuous protruding structure 23C is arranged on the end face of the vertical wall end.

Embodiment 4

[0051] This embodiment only describes the difference from the above embodiment, and other technical features are the same as the above embodiment. In this embodiment, the top wall 22A is an inclined wall, and the top wall 22A slopes downward from the outer ring to the inner ring, that is, the height of the outer ring is placed at the top of the air guiding device, and the inner ring is placed at the top of the air guiding device. below the outer ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com