Novel efficient subway construction shield device

A shield and high-efficiency technology, applied to mining equipment, earth square drilling, tunnels, etc., can solve problems such as unsmooth excavation, easy-to-contaminate construction site construction efficiency, etc., and achieve simple structure, increased cleaning costs, and scientific and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

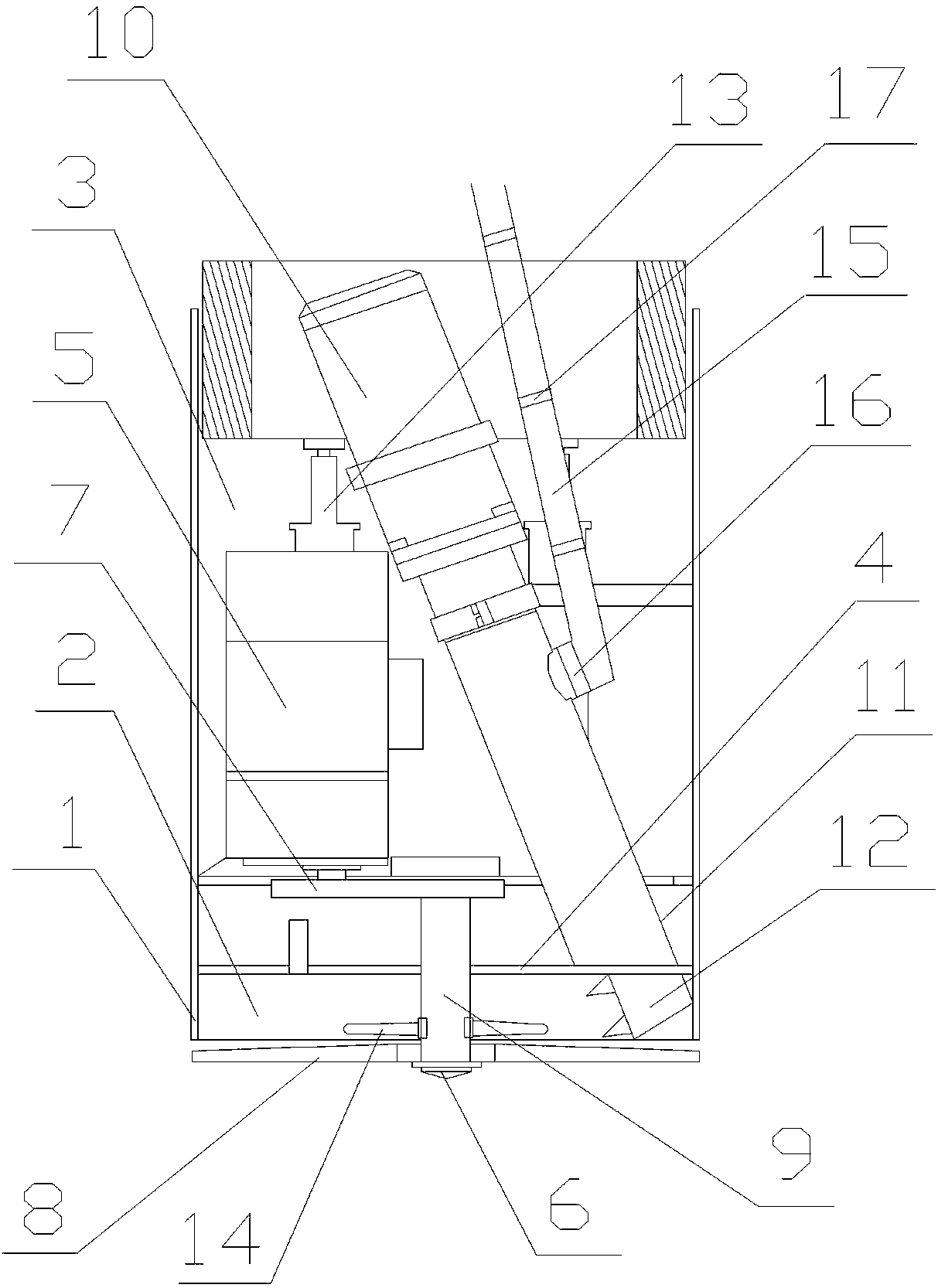

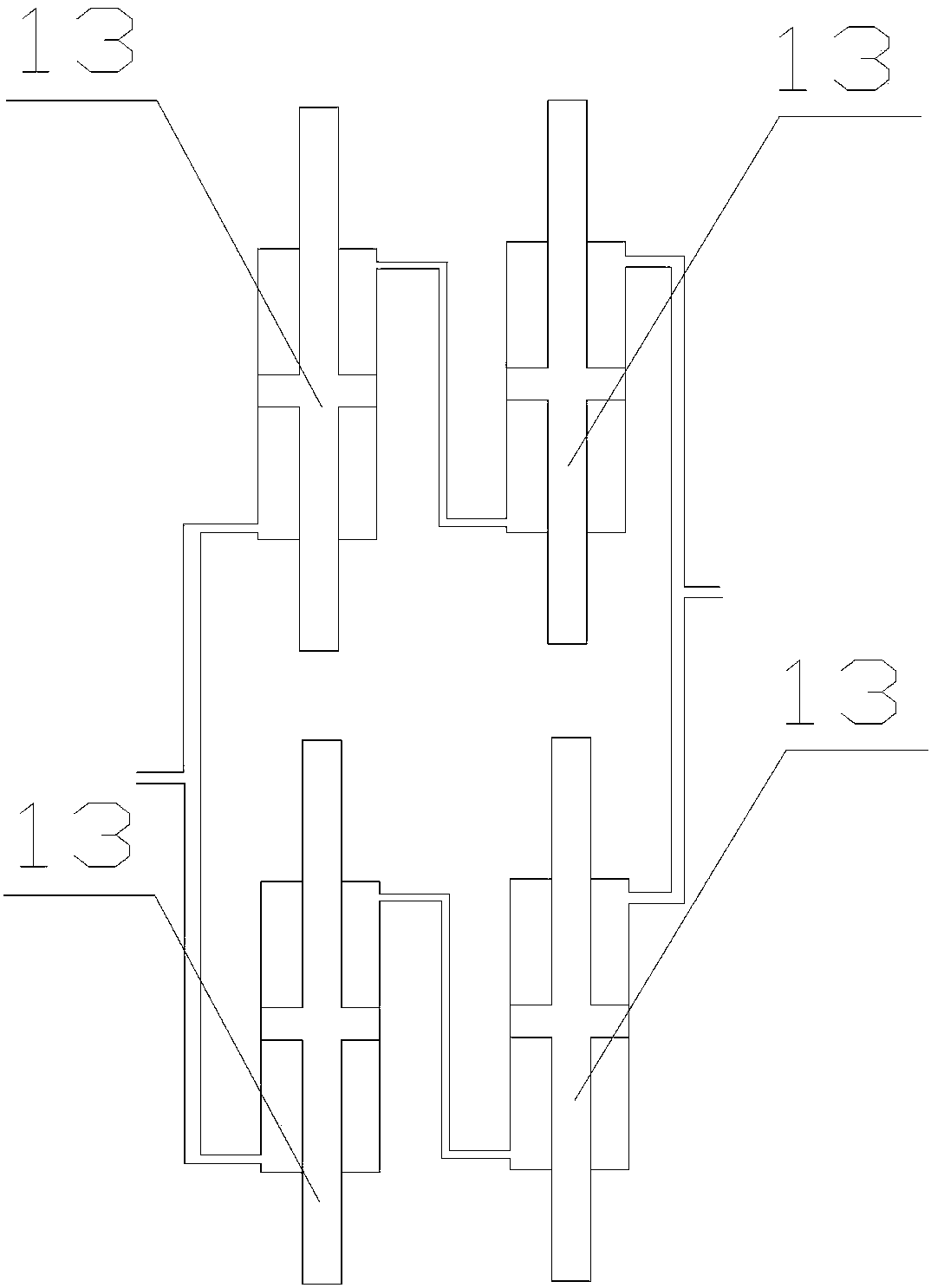

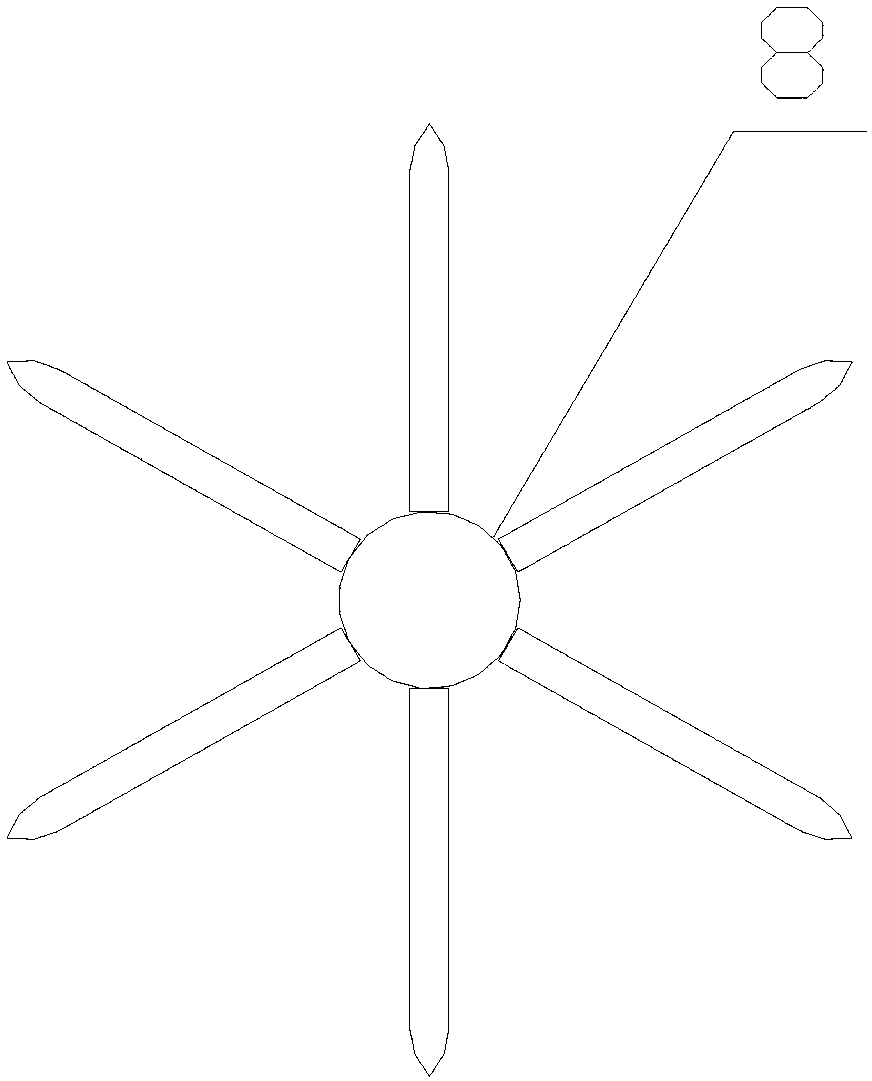

[0016] Such as Figure 1-3 As shown, a new type of high-efficiency shield tunneling equipment for subway construction includes a cylindrical shield shell 1, which is set in the shield shell 1 and divides the shield shell 1 into a soil cabin 2 at the front and an engine room 3 at the rear The bulkhead 4, the cutterhead drive motor 5 fixed in the cabin 3, the cutterhead bearing 6 at the center of the bulkhead 4, matched with the cutterhead bearing 6, one end stretches into the cabin 3 and passes through the speed regulating gear Group 7 is connected with the drive shaft of cutterhead drive motor 5, the other end stretches into soil cabin 2 and the end of this end is connected with cutterhead shaft 9 of cutterhead 8, is located on the cutterhead shaft 9 and is located at bulkhead 4 and The mixing paddle 14 between the cutter heads 8 is fixed on the unearthed drive motor 10 in the engine room 3, one end is fixed in the engine room 3 and is sleeved on the shell of the unearthed dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com