Deep-sea water separation guide pipe male connector end sealing structure

A water-resistant conduit and end sealing technology, which is applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of reducing the sealing effect and damage of the sealing ring, and achieves the effects of easy manufacture, avoiding damage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

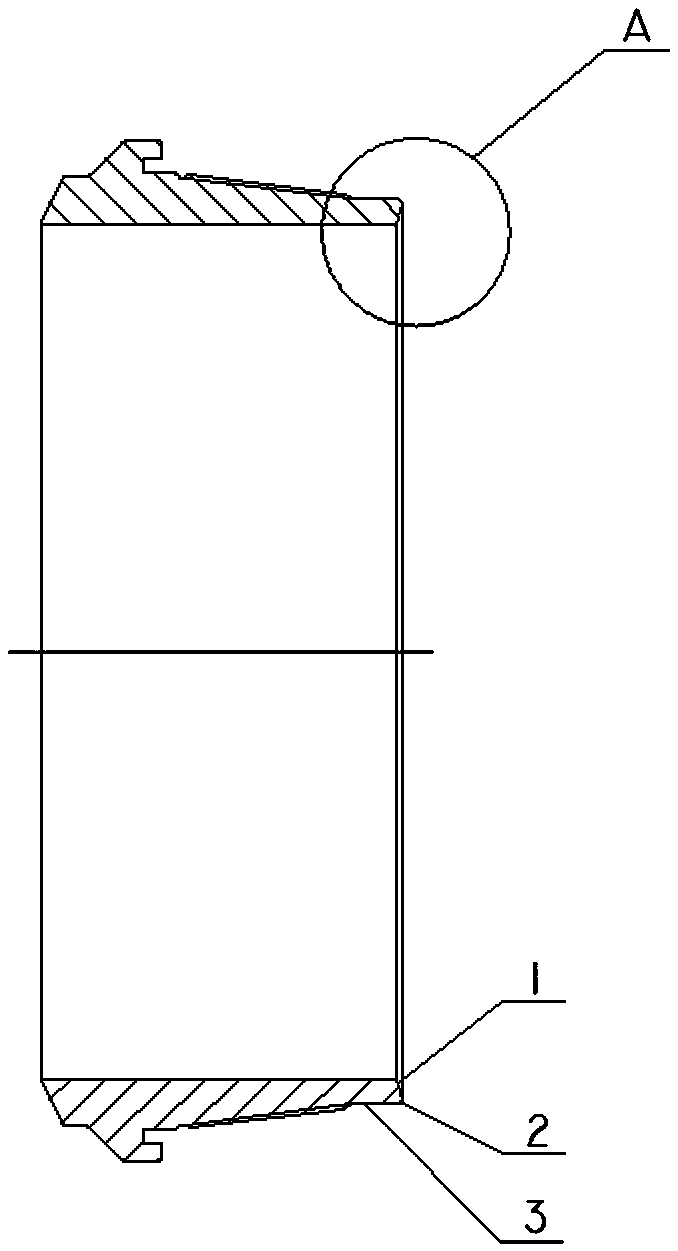

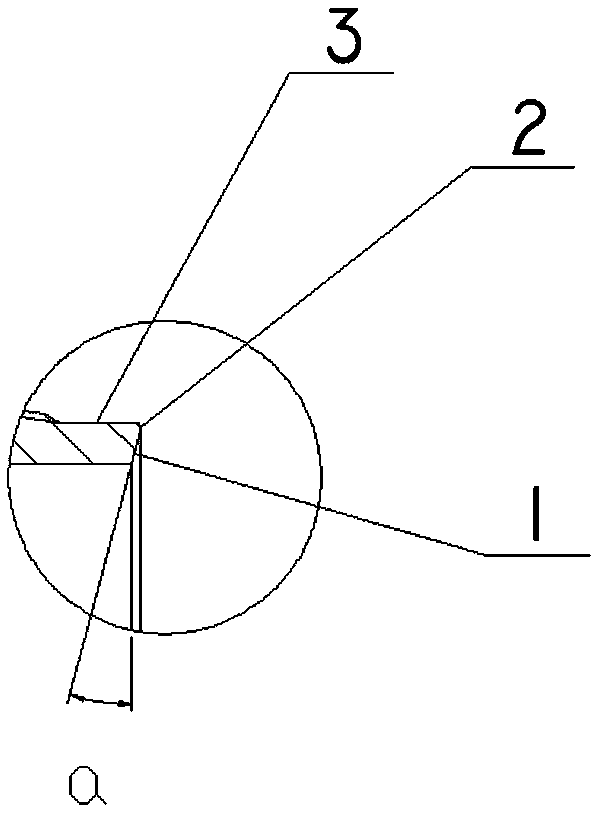

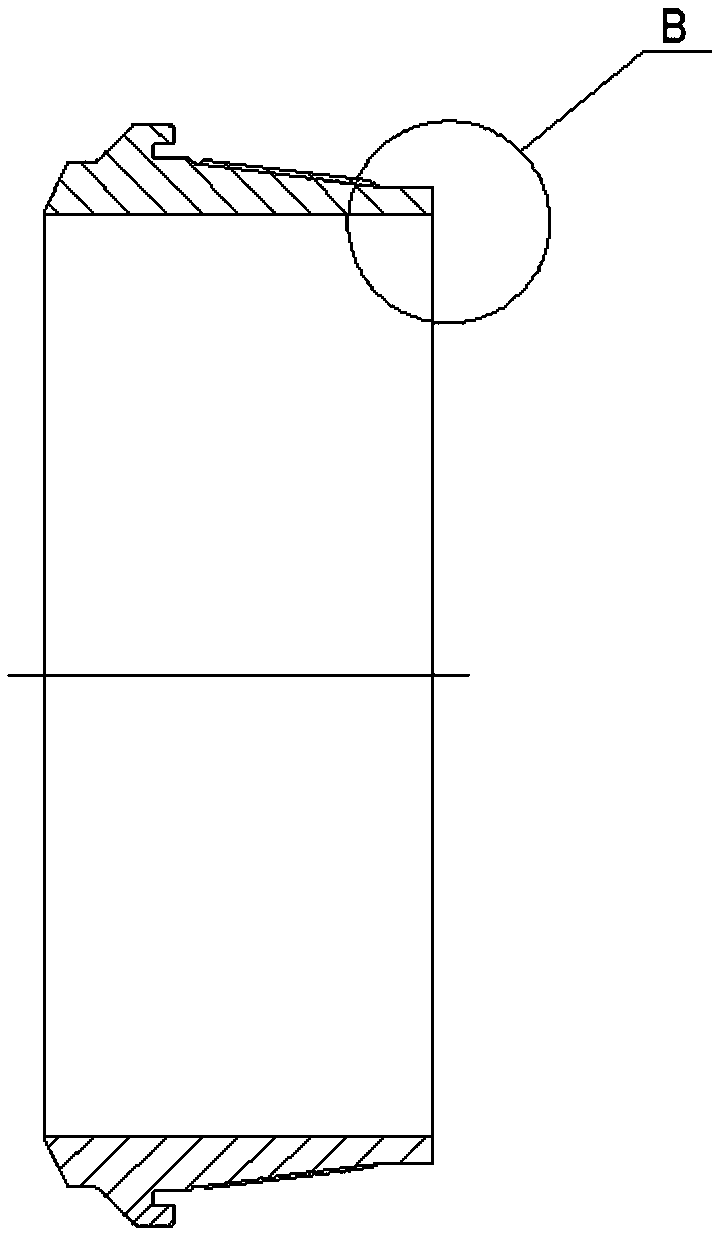

[0018] This embodiment is a male connector of a deep-sea riser with a caliber of 16 inches. The sealing structure at the end of the male connector is composed of a connector end face 1 , an outer corner 2 and an outer wall 3 . In this embodiment, the axial concave bevel angle α of the end face 1 of the joint is 12 0 . The outer corner 2 is located at the junction of the outer wall 3 and the joint end face 1, and the outer corner 2 is in a convex arc shape, and the arc radius R of the round corner is 2.75 mm.

Embodiment 2

[0020] This embodiment is a 40-inch deep sea riser male joint. The sealing structure at the end of the male joint is composed of a joint end face 1 , an outer corner 2 and an outer wall 3 . In this embodiment, the axial concave bevel angle α of the end face 1 of the joint is taken as 15 0 . The outer corner 2 is located at the junction of the outer wall 3 and the joint end face 1, and the outer corner 2 is in a convex arc shape, and the arc radius R of the rounded corner is 3.5mm.

[0021] In the present invention, the end face of the male joint of the deep-sea water-resisting conduit is designed as an axially concave oblique angle. The sealing structure of the inclined plane is simple and reasonable. Under the constraints of the female joint, the elastic deformation part of the sealing ring plays a role in enhancing the sealing performance in the structure. It is also important to adopt a circular arc-shaped design for the outer corner 2 in the end sealing structure. The ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com