Preparation method of metal nanosheet, metal nanosheet, application and cathode active material

A negative electrode active material and metal nanotechnology, which is applied in the field of metal nanosheets, can solve the problems of increasing the oxidation degree of the metal surface, no improvement, consumption, etc., and achieve the effect of low cost, good quality, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

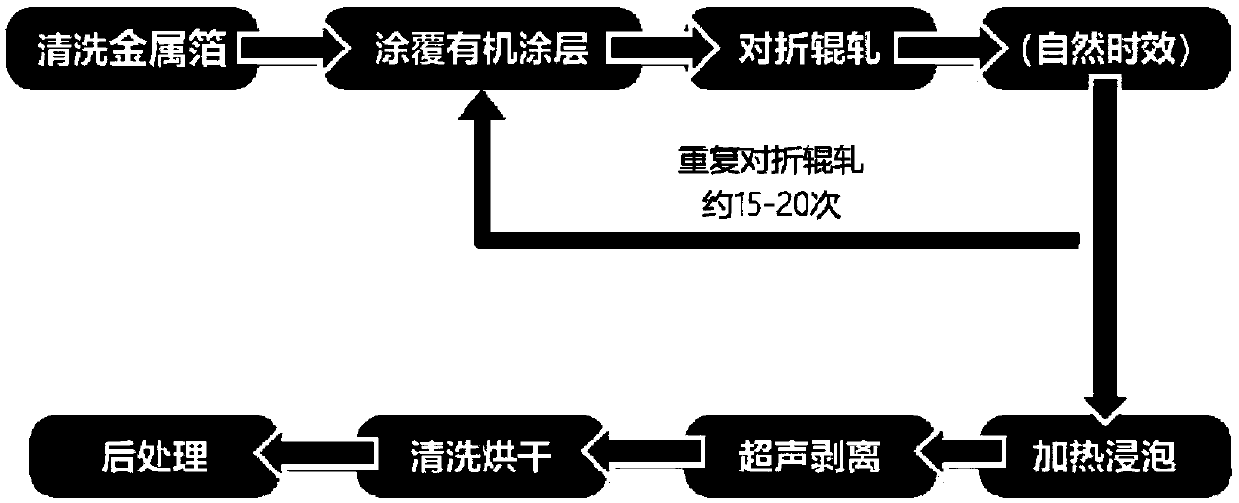

[0079] In a first aspect, in at least one embodiment, a method for preparing metal nanosheets is provided, comprising the following steps:

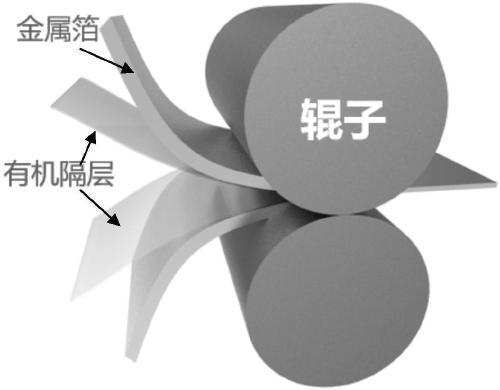

[0080] A metal foil is provided, an organic coating is coated on the surface of the metal foil, and then the metal foil coated with the organic coating is folded in half and pressed multiple times to obtain a metal-organic coating composite sheet;

[0081] The metal sheet and the organic coating in the metal-organic coating composite sheet are separated to obtain the metal nano sheet.

[0082] The invention coats an organic coating on the surface of a metal foil, folds it in half and presses it multiple times to obtain a metal-organic coating composite sheet; separates the metal sheet and the organic coating in the metal-organic coating composite sheet, Metal nanosheets were obtained.

[0083] In view of the fact that the rolling method to prepare metal nanosheets is the most suitable method among many methods at present, due to the duct...

Embodiment 1-4

[0168] A method for preparing metal nanosheets, comprising the following steps:

[0169] Provide a metal foil, coat the surface of the metal foil with an organic coating, then fold the metal foil coated with the organic coating in half and press it multiple times to obtain a metal-organic coating composite sheet;

[0170] The metal sheet and the organic coating in the metal-organic coating composite sheet are separated to obtain the metal nano sheet.

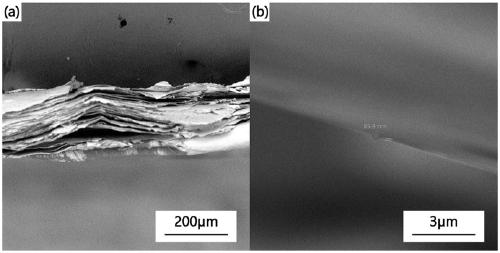

[0171] The metal types and organic coating materials used in Examples 1-4 are all the same, the difference mainly lies in the number of times of rolling (folding in half), the main operating conditions of Examples 1-4 and the size of the metal nanosheets obtained are as shown in Table 1 Show.

[0172] Table 1 The operating conditions of Examples 1-4 and the size of the metal nanosheets obtained

[0173]

Embodiment 5-10

[0175] Embodiment 5-10 is compared with embodiment 4, and the organic coating material that adopts is all the same, and difference mainly lies in metal type and rolling (folding in half) times, the main operating conditions of embodiment 4 and embodiment 5-10 And the obtained metal nanosheet size is shown in Table 2.

[0176] Table 2 The operating conditions of Examples 4-10 and the size of the metal nanosheets obtained

[0177]

[0178]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com