Self-ignition rocket fuel and self-ignition propellant

A rocket fuel and propellant technology, applied in the field of bicomponent liquid rocket propellant, can solve the problems of reducing practical application value, failing to meet practical needs, and difficulty in large-scale production, so as to facilitate multiple ignitions and start, improve system Reliability and maintenance of safety, safety and stability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

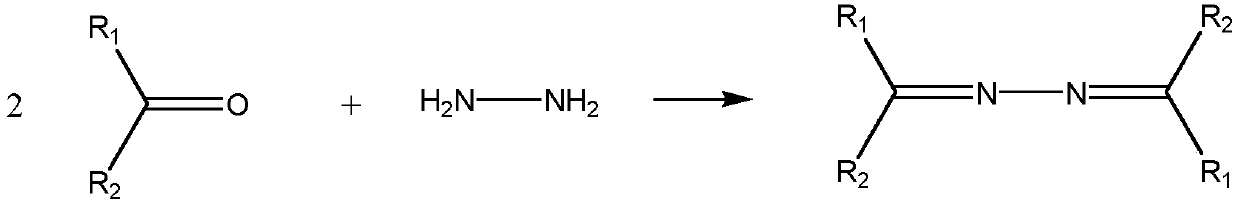

[0028] Embodiment 1: the synthesis of cyclopropyl ketone azine (CPMKA):

[0029] In a 500mL three-necked reaction flask equipped with a stirrer, a thermometer, and a constant pressure dropping funnel, add 100mL of ethanol and 62.5g (1mol) of 80% hydrazine hydrate, dropwise add 168g (2mol) of cyclopropyl ketone, and heat to reflux for 16 hours , the reactant was extracted with ether, dried, concentrated under reduced pressure and then rectified to obtain about 74g of light yellow transparent liquid CPMKA product with a yield of about 45%. Its structure and properties are shown in Table 1.

Embodiment 2

[0030] Embodiment 2: the synthesis of acetone azine (ATA)

[0031] In a 500mL three-necked reaction flask equipped with a stirrer, a thermometer, and a constant pressure dropping funnel, add 150mL of ethanol and 87g (1.5mol) of 80% hydrazine hydrate, dropwise add 252g (3mol) of acetone, and heat to reflux for 12 hours. Extracted with ether, dried, concentrated under reduced pressure and then rectified to obtain about 134 g of ATA product as light yellow transparent liquid with a yield of about 80%. Its structure and properties are shown in Table 1.

Embodiment 3

[0032] Embodiment 3: the synthesis of butanone azine (DTA)

[0033] In a 500mL three-neck reaction flask equipped with a stirrer, a thermometer, and a constant pressure dropping funnel, add 150mL of ethanol and 26g (0.5165mol) of 80% hydrazine hydrate, dropwise add 74.5 (1.033mol) of methyl ethyl ketone, heat and reflux for 12 hours, and react The product was extracted with ether, dried, concentrated under reduced pressure and then rectified to obtain about 69 g of light yellow transparent liquid DTA product with a yield of 94.69%. Its structure and properties are shown in Table 1.

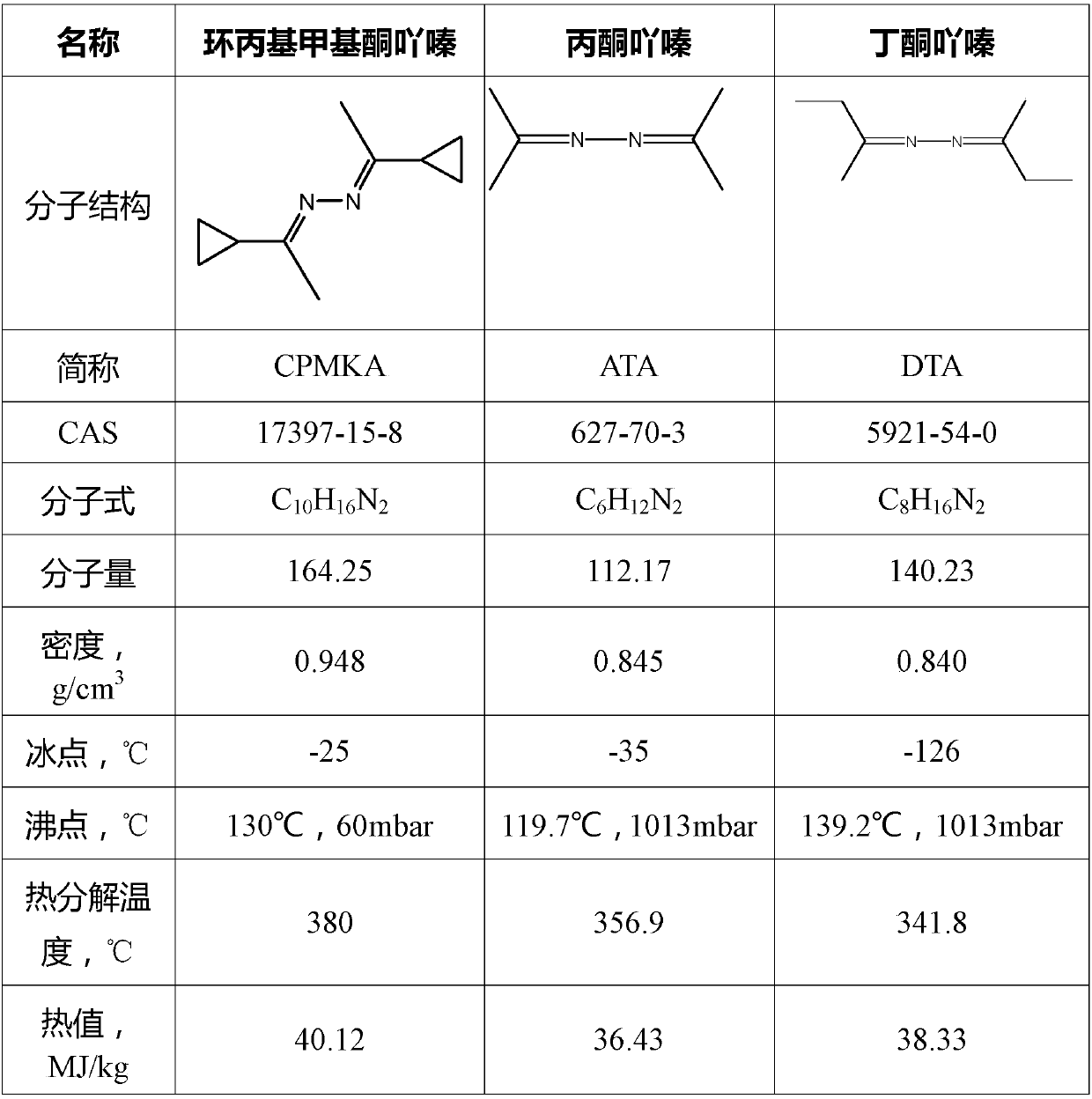

[0034] The structure and performance of many substituted azine compounds obtained in table 1 embodiment 1-3

[0035]

[0036] And it can be seen from the data in Table 1 that the three kinds of spontaneous combustion additives have good compatibility with rocket kerosene, and have lower freezing points, and better low-temperature performance; higher boiling points, will not produce hydrazines ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com