Quaternary ammonium-sulfonation microcrystalline cellulose stabilizer and application of stabilizer to cellular herbicides

A microcrystalline cellulose, sulfonation technology, applied in herbicides and algicides, applications, biocides, etc., can solve the problems of reduced efficacy, aggravated pollution, poor slow release, etc., and achieves dispersion and suspension stability. Improved, broad-spectrum herbicidal performance, improved disintegration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

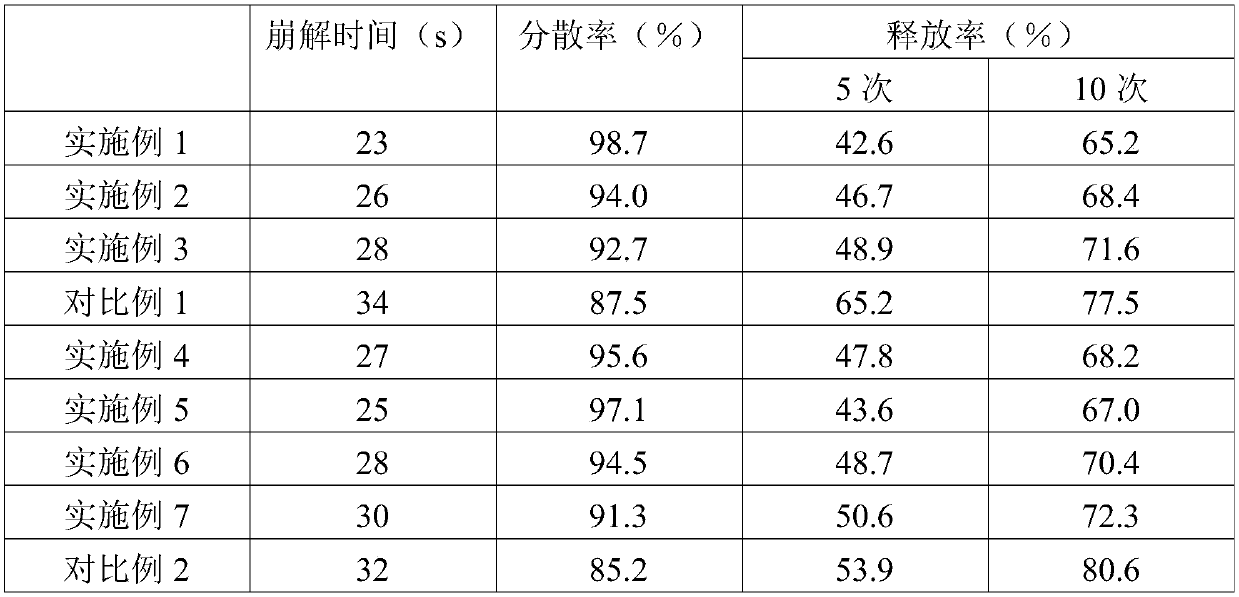

Examples

Embodiment 1

[0054] A highly efficient and rapidly disintegrating cellular herbicide is prepared from the following raw materials in parts by weight:

[0055] 55 parts of herbicide, 13 parts of wetting agent, 5 parts of disintegrant, 7 parts of quaternary ammonium-sulfonated microcrystalline cellulose stabilizer, 40 parts of carrier, 450 parts of emulsifier aqueous solution with a mass fraction of 0.8%, binder 5 servings.

[0056] The herbicide is alachlor. The wetting agent is sodium lauryl sulfate. The disintegrant is a mixture of urea and sodium chloride in a mass ratio of 1:1. The binder is a mixture of maltodextrin and xanthan gum in a mass ratio of 1:3.

[0057] The preparation method of the quaternary ammonium-sulfonated microcrystalline cellulose stabilizer is as follows: Weigh 12 g of microcrystalline cellulose, add 300 mL of NaOH aqueous solution with a mass concentration of 0.5%, heat up to 95 ° C, keep at 95 ° C for 60 min, cool After reaching 30°C, filter with suction, add...

Embodiment 2

[0064] Compared with Example 1, the only difference is that in this Example 2, the preparation method of the quaternary ammonium-sulfonated microcrystalline cellulose stabilizer is as follows: Weigh 12 g of microcrystalline cellulose, add 300 mL of In NaOH aqueous solution, heat up to 95°C, keep warm at 95°C for 60min, cool to 30°C and filter with suction, add the filter cake to 300mL NaOH aqueous solution with a mass concentration of 10%, let it stand at 25°C for 150min, and suction filter, the filter cake Dry at 30°C to constant weight to obtain alkali-treated microcrystalline cellulose. Take 8.0 g of alkali-treated microcrystalline cellulose, add it to 200 mL of acetone, add 10 mL of NaOH aqueous solution with a mass concentration of 10% at a rate of 1 mL / min at 25 ° C and 200 rpm under magnetic stirring, and then add 16 g of 3-chloro- 2-Hydroxypropyltrimethylammonium chloride, heat up to 45°C, react at 45°C for 3 hours, then adjust the pH value to 7.0 with 1mol / L hydrochlo...

Embodiment 3

[0066]Compared with Example 1, the only difference is that in this Example 3, the preparation method of the quaternary ammonium-sulfonated microcrystalline cellulose stabilizer is as follows: Weigh 12 g of microcrystalline cellulose, add 300 mL of In NaOH aqueous solution, heat up to 95°C, keep warm at 95°C for 60min, cool to 30°C and filter with suction, add the filter cake to 300mL NaOH aqueous solution with a mass concentration of 10%, let it stand at 25°C for 150min, and suction filter, the filter cake Dry at 30°C to constant weight to obtain alkali-treated microcrystalline cellulose. Take 8.0 g of alkali-treated microcrystalline cellulose, add it to 200 mL of acetone, add 10 mL of NaOH aqueous solution with a mass concentration of 10% at a rate of 1 mL / min at 25 ° C and 200 rpm under magnetic stirring, and then add 16 g of 3-chloro- 2-Hydroxypropyltrimethylammonium chloride, heat up to 45°C, react at 45°C for 3 hours, then adjust the pH value to 7.0 with 1mol / L hydrochlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com