Automatic knotting device of full-automatic doubling mechanism

An automatic knotting and knotting device technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of low knotting success rate, large space occupation, difficult processing and assembly, etc. Compact, high reliability, solve the effect of low success rate of automatic knotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

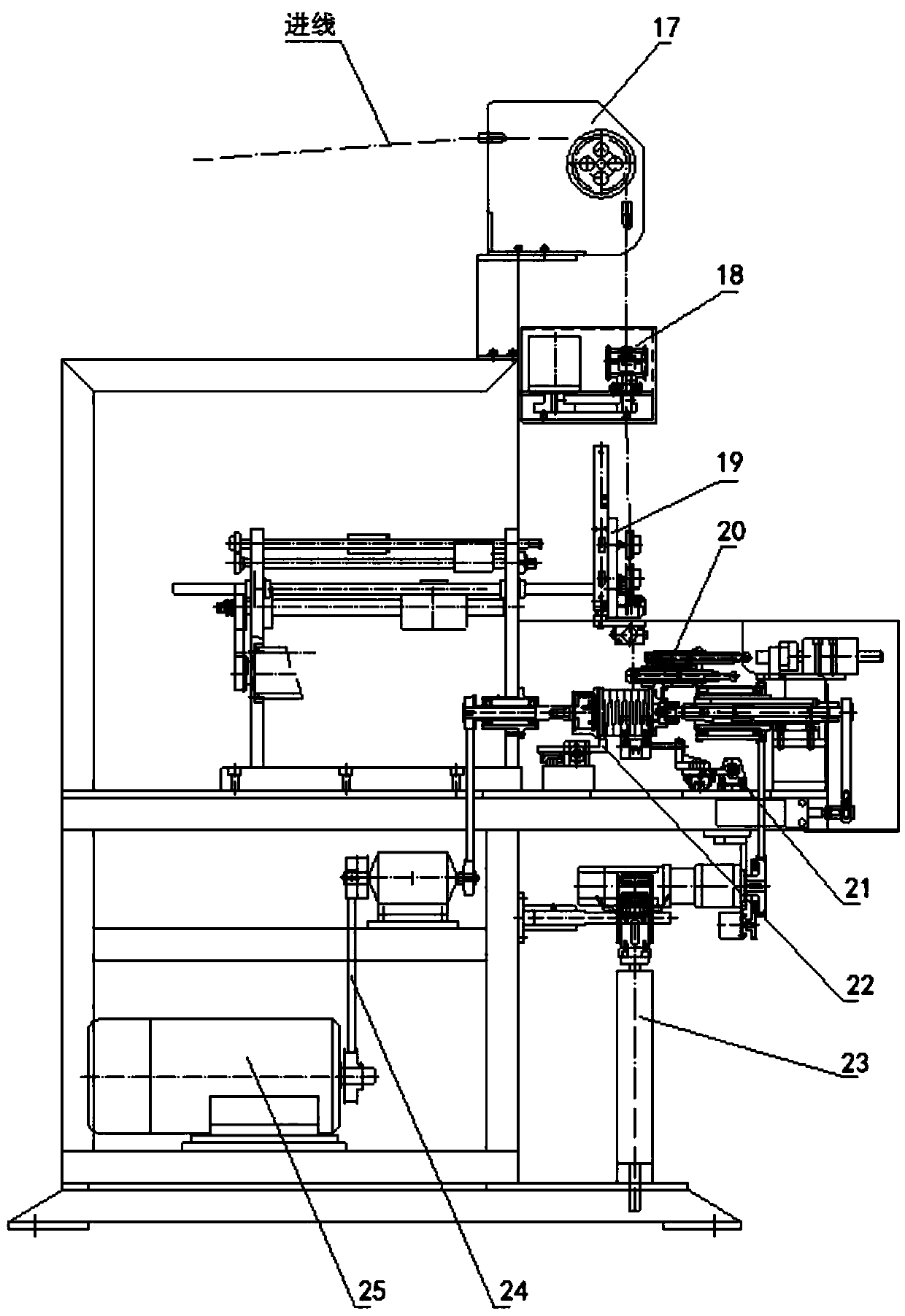

[0025] The knotting device of this embodiment includes a movable top, a fixed top, a wire winding mechanism, a wire clamping mechanism, a wire pushing mechanism, and a knotting drive device, wherein the wire winding mechanism is installed on the shell of the movable top, and on the shell of the fixed top. Wire ingot is installed, and knotting device of the present invention is used for knotting the silk ends of the silk thread of the last several turns on the wire ingot.

[0026] The wire winding mechanism includes a wire winding disk, a rotating driving device for driving the winding disk to rotate, and a horizontal driving device for driving the winding disk to move horizontally.

[0027] The thread clamping mechanism in this embodiment includes a thread clamping rod and a first sleeve. The thread clamping rod is located in the first sleeve and can move telescopically in the first sleeve. A first rectangular spring is arranged in the first sleeve, and the first rectangular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com