Overlapping and assembling station for panel light assembling line

A lighting and wiring technology, applied in the direction of manufacturing tools, workpiece clamping devices, workshop equipment, etc., can solve the problems of uneven assembly quality, low yield rate, uncontrollable quality, etc., to improve the line drawing speed, The effect of fast execution, improvement of assembly efficiency and assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

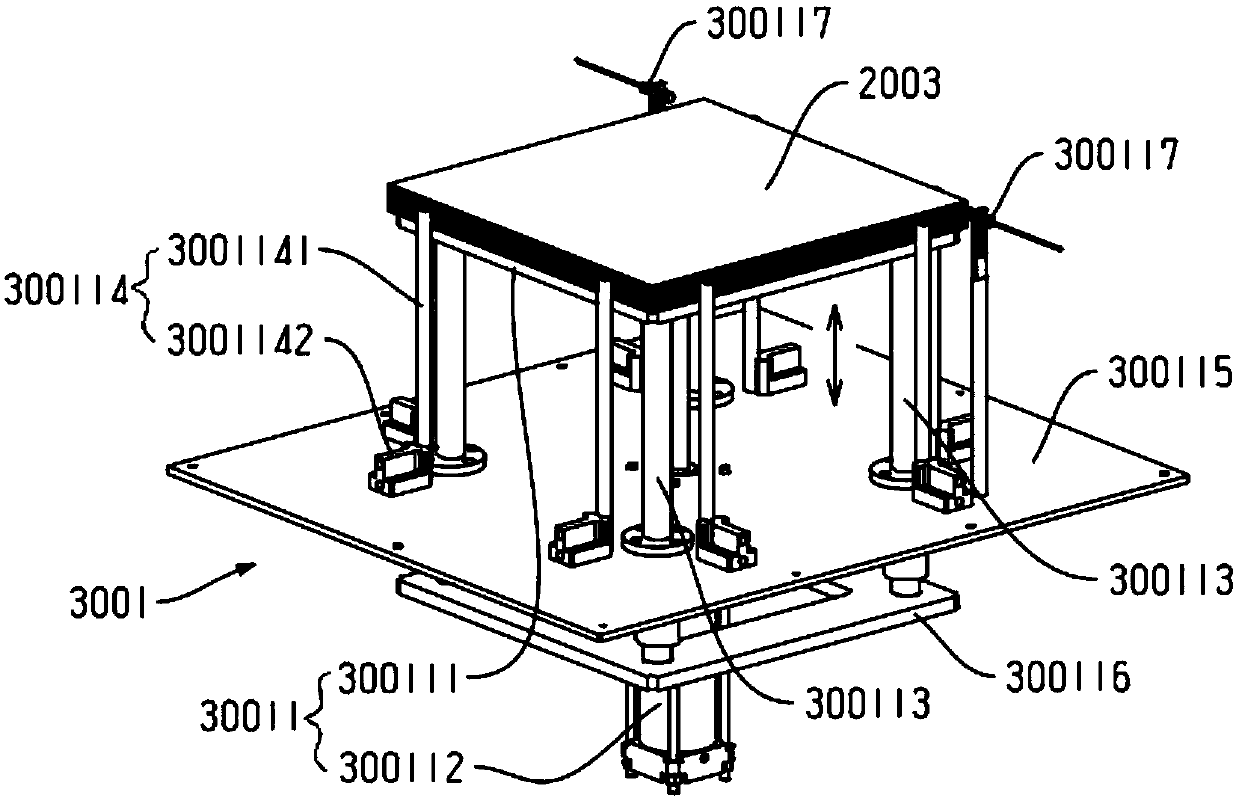

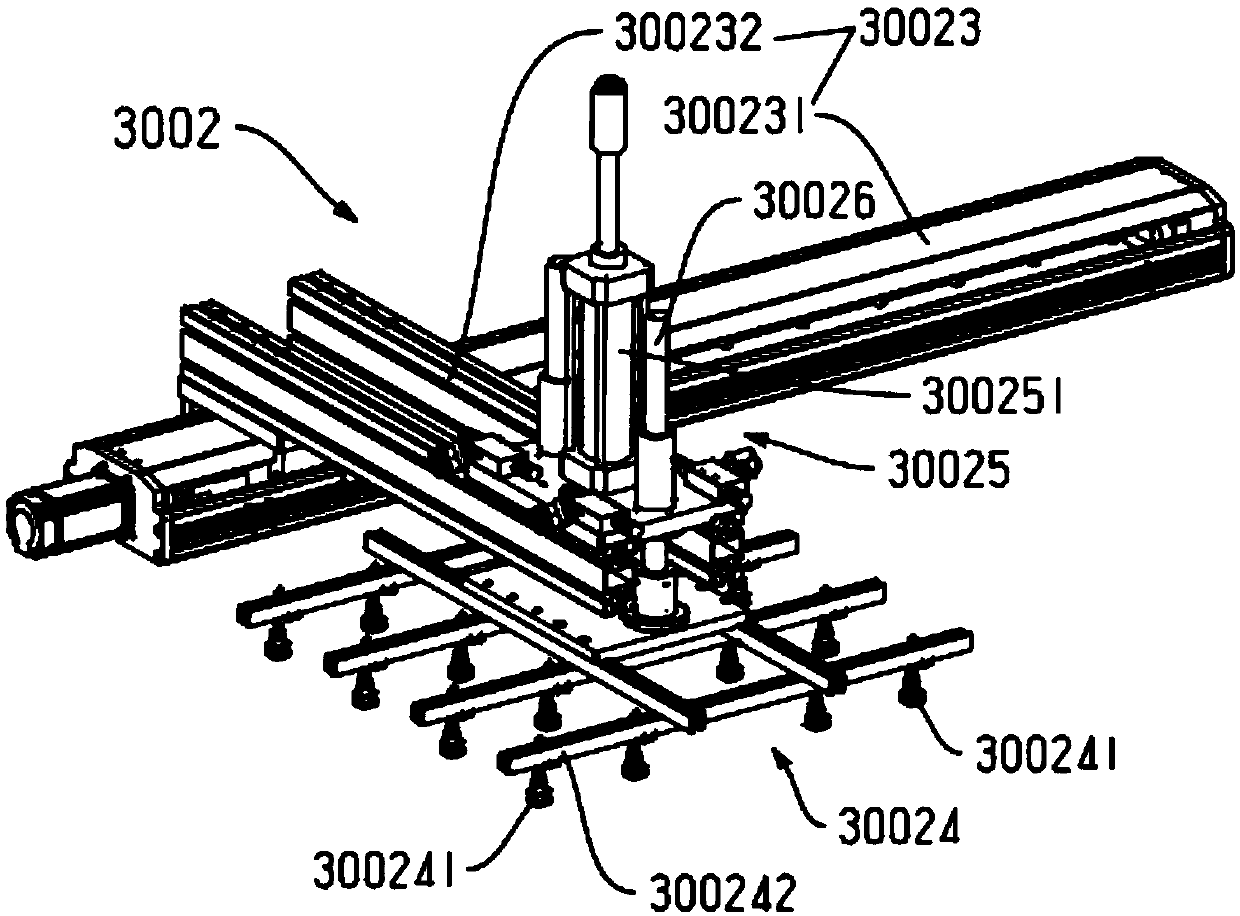

[0040] Embodiment: a stacking station for a panel lamp assembly line, such as figure 1 As shown: it includes a stacking frame 3004 and a feeding device 3001 connected to the stacking frame, a line drawing device 200 and a transmission line body 100, between the feeding device and the line drawing device and the line drawing device A grabbing device 3002 is provided between the transmission line body and the grabbing device includes a first grabbing device 30021 and a second grabbing device 30022 with the same structure, and the workpiece 2003 to be assembled passes through the first grabbing device 30022. The device grabs and places it on the line-drawing device. After the line-drawing device completes the line-drawing action for the workpiece, the second grabbing device grabs and places the workpiece on the light frame 1005 of the panel lamp. The light frame is installed on the transmission line body;

[0041] The feeding device includes an elevating bin 30011, and several w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com