A Pressure Adjustable Rotary Kiln Wheel Belt Grinding Device

A rotary kiln and wheel belt technology, applied in grinding/polishing safety devices, grinding/polishing equipment, grinding machine parts, etc., can solve the problems of low labor efficiency, high labor intensity, and easily broken grinding wheels. The effect of improving grinding efficiency, increasing pressure and optimum applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

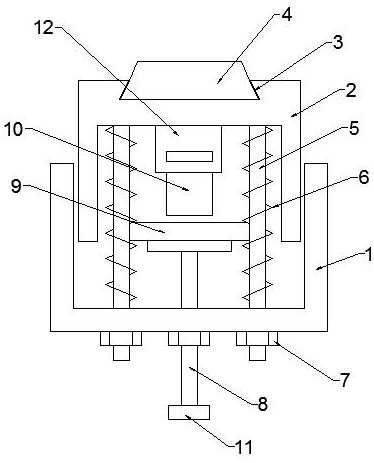

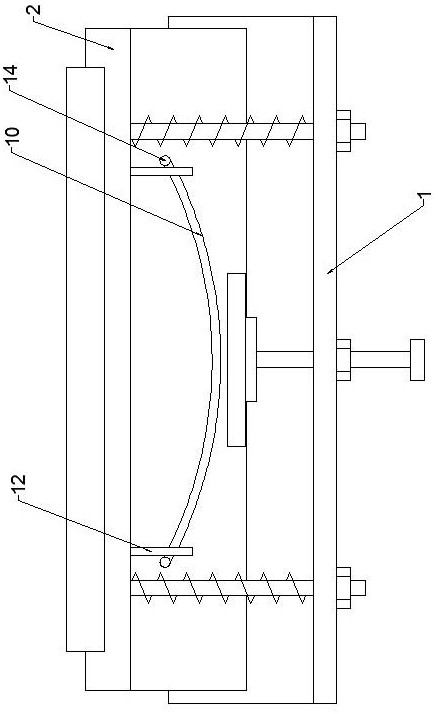

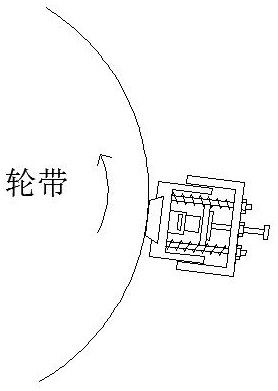

[0017] Such as figure 1 As shown, a pressure-adjustable rotary kiln tire grinding device includes a U-shaped limiting groove 1, and a U-shaped movable seat 2 is arranged in the U-shaped limiting groove 1, and the opening of the U-shaped movable seat 2 is downward and inverted. Buckled in the U-shaped limit groove 1, the top surface of the U-shaped movable seat 2 is provided with a positioning groove 3, and the matching grinding wheel 4 is installed in the positioned groove 3, and the two ends of the bottom surface of the U-shaped movable seat 2 are provided with lifting lugs 12. The ear 12 is provided with a leaf spring 13 with the convex surface facing downward, and both ends of the leaf spring 13 are provided with limit blocks 14 to prevent the leaf spring 13 from being dislocated. Rod 5, guide rod 5 outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com