Axle hole processing clamp and method for dual-fluted-disc-driven knotter bracket

A knotter and hole processing technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., to achieve the effect of eliminating repeated alignment, convenient and simple loading and unloading of workpieces, and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

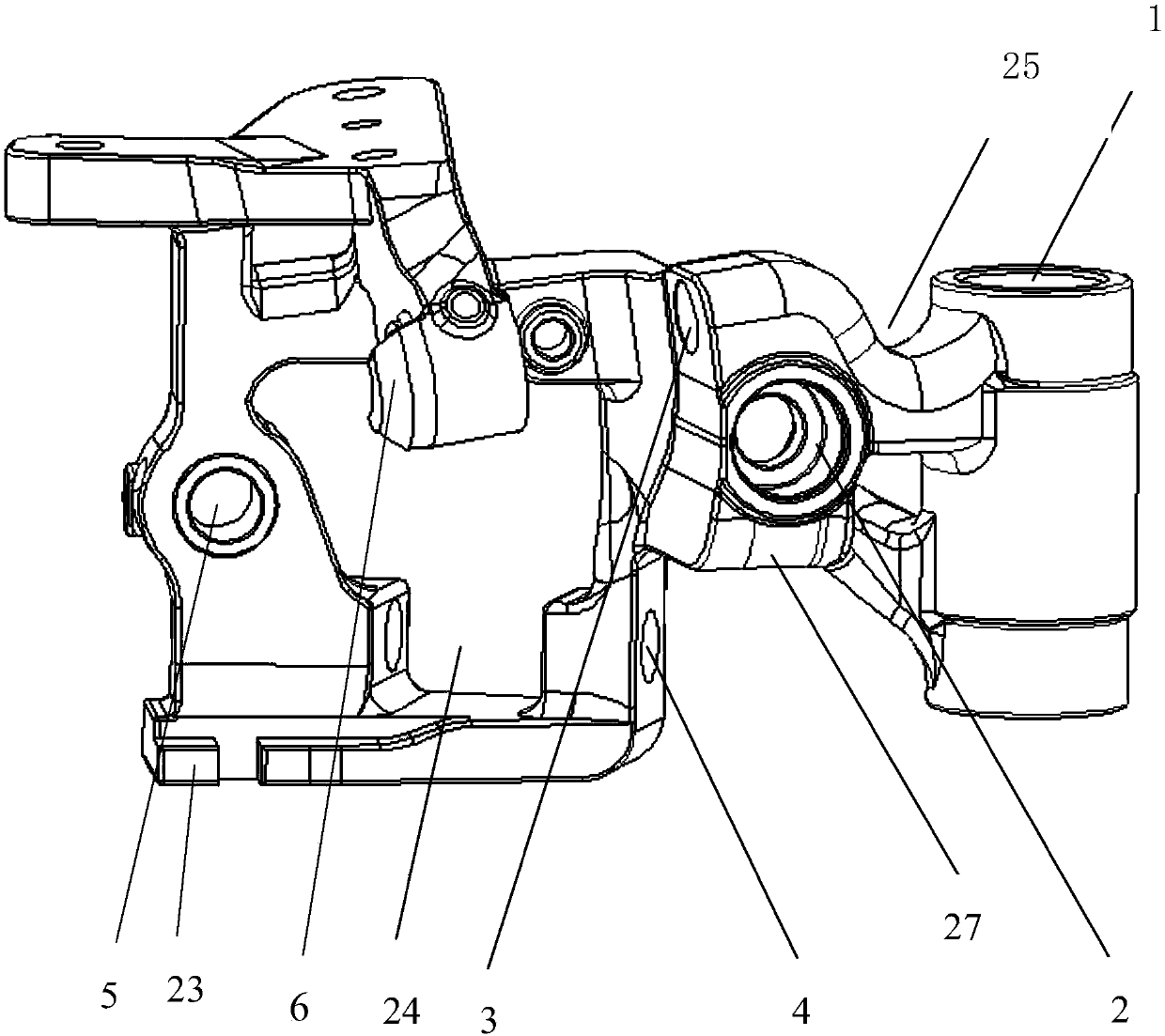

[0046] figure 1 Shown is the bracket of the double tooth disc drive knotter according to the present invention, including a main shaft hole 1, a knife arm shaft hole 2, a knotting nozzle shaft hole 3, a worm shaft hole 4, a rope clamp disc shaft hole 5 and a knotting nozzle shaft Hole cam surface6.

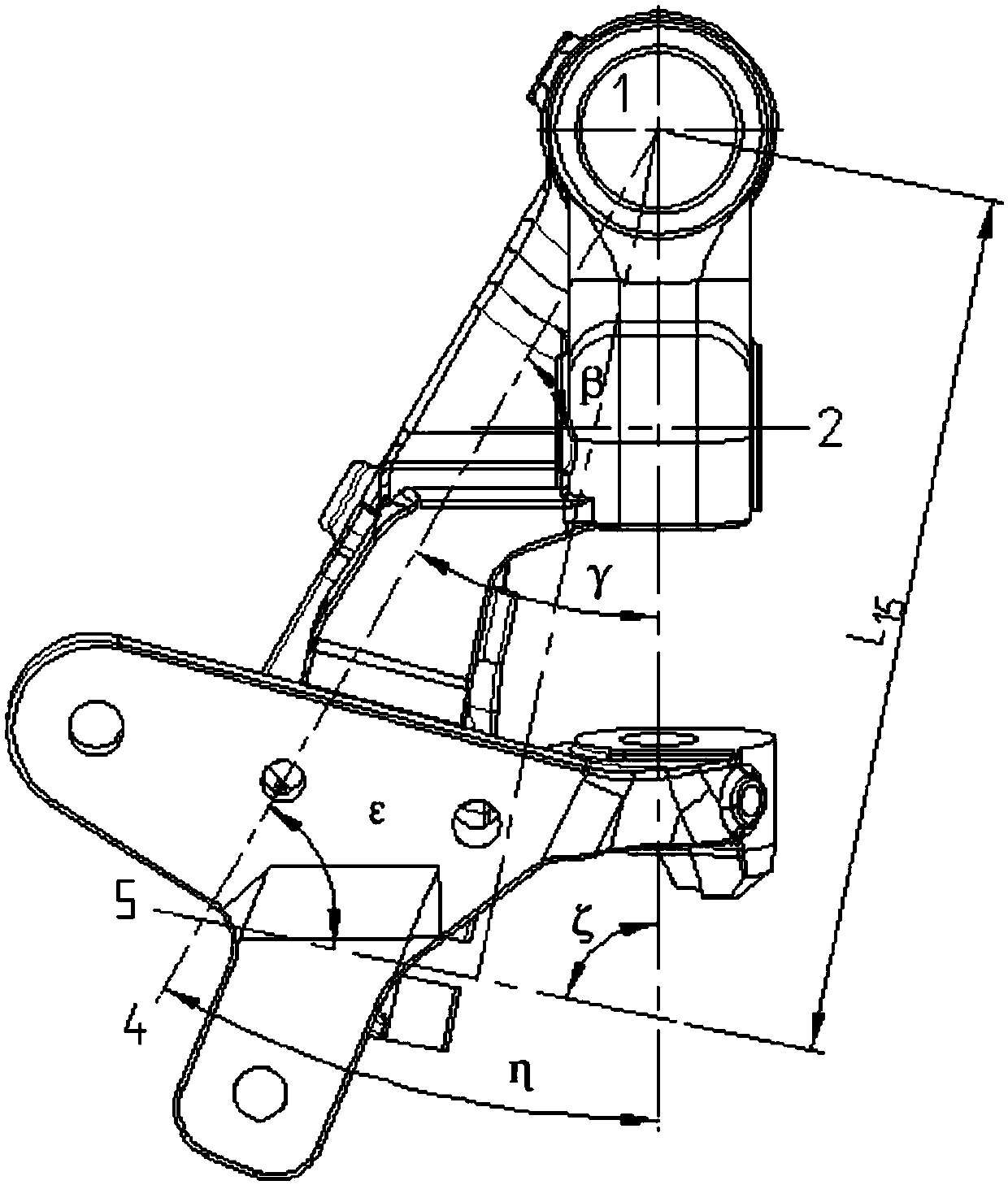

[0047] figure 2Shown is the spatial angle relationship between the shaft holes of the knotter bracket driven by the double toothed disc: the angle between the main axis line of the knotter and the axis line of the knotting mouth is α = 78°, the axis line of the worm and The angle between the axis of the knife arm is β=60°, the axis of the worm and the axis of the knotting nozzle γ=30°, the axis of the shaft and the axis of the rope clamp ε=72°, the axis of the knotting nozzle With the axis line ζ=78° of the rope clamping disc, the axis line of the knotting nozzle and the axis line η=60 ° of the rope clamping disc.

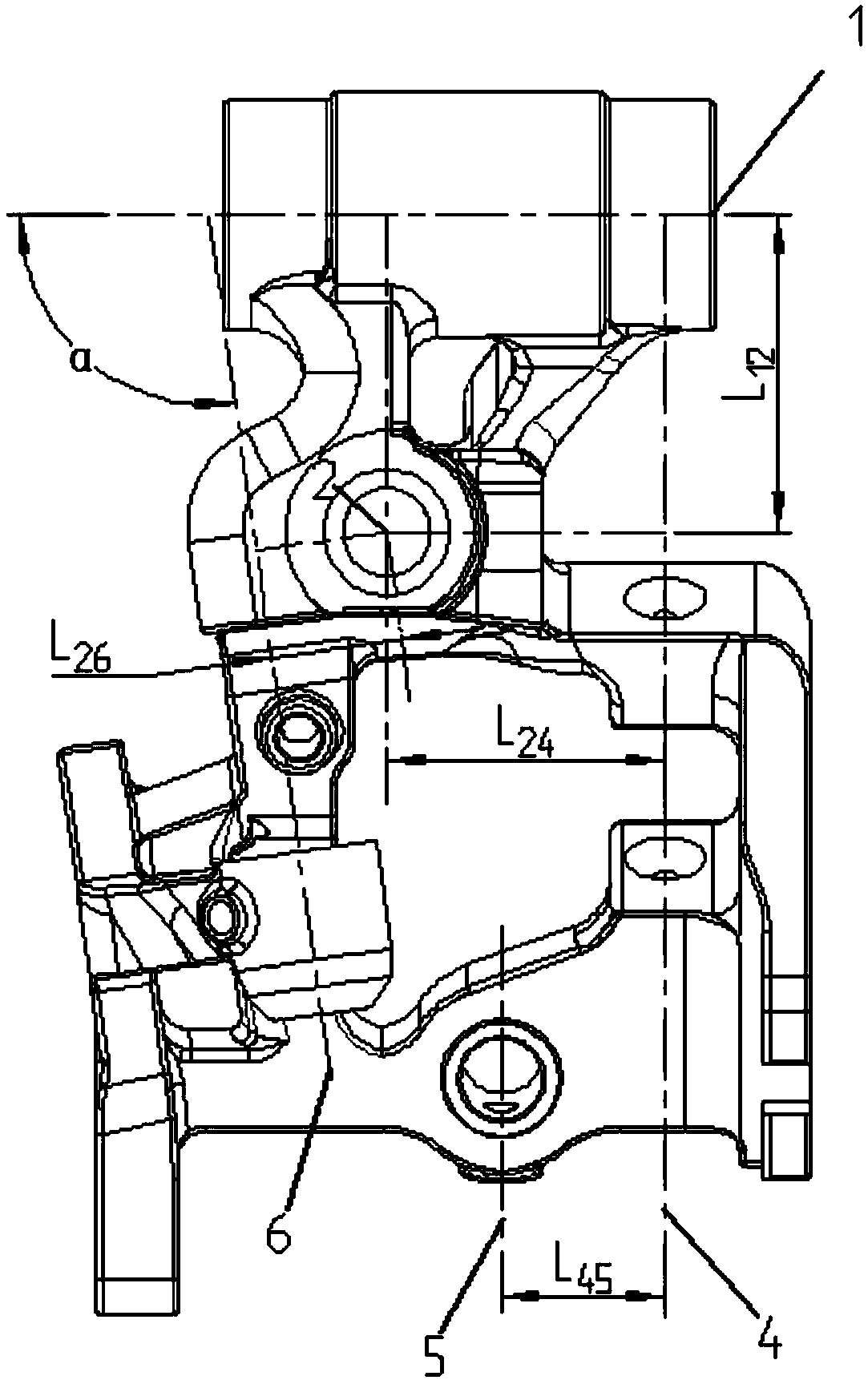

[0048] image 3 Shown is an embodiment of the spatial positi...

Embodiment 2

[0059] A method for machining shaft holes by using the double toothed discs described in Embodiment 1 to drive the shaft hole processing jig of the knotter bracket. The absolute coordinate system setting for processing the knotter bracket on a five-axis numerical control machine tool is set by clamping and punching The double toothed disk of the knotter bracket drives the knotter bracket shaft hole processing fixture to be fixed on the worktable of the five-axis CNC machine tool, and the bolts on the bottom plate 7 of the special fixture are adjusted so that the knotter bracket blank with the grooved plane 23 remains Horizontal, set as the reference plane; use the dial indicator to measure the outer edge of the main shaft hole of the knotter support, determine the axis position of the main shaft hole of the knotter support, set the axis of the main shaft hole of the knotter support as the reference axis, and the reference axis and The reference plane maintains a vertical inters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com