Precision forming method of aluminum alloy reinforcement plate rectangular forging part

A precision forming and aluminum alloy technology, applied in metal processing equipment, etc., can solve the problems affecting the forming quality of forgings, complex metal flow, large projected area, etc., and achieve the effects of low labor intensity, saving metal materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

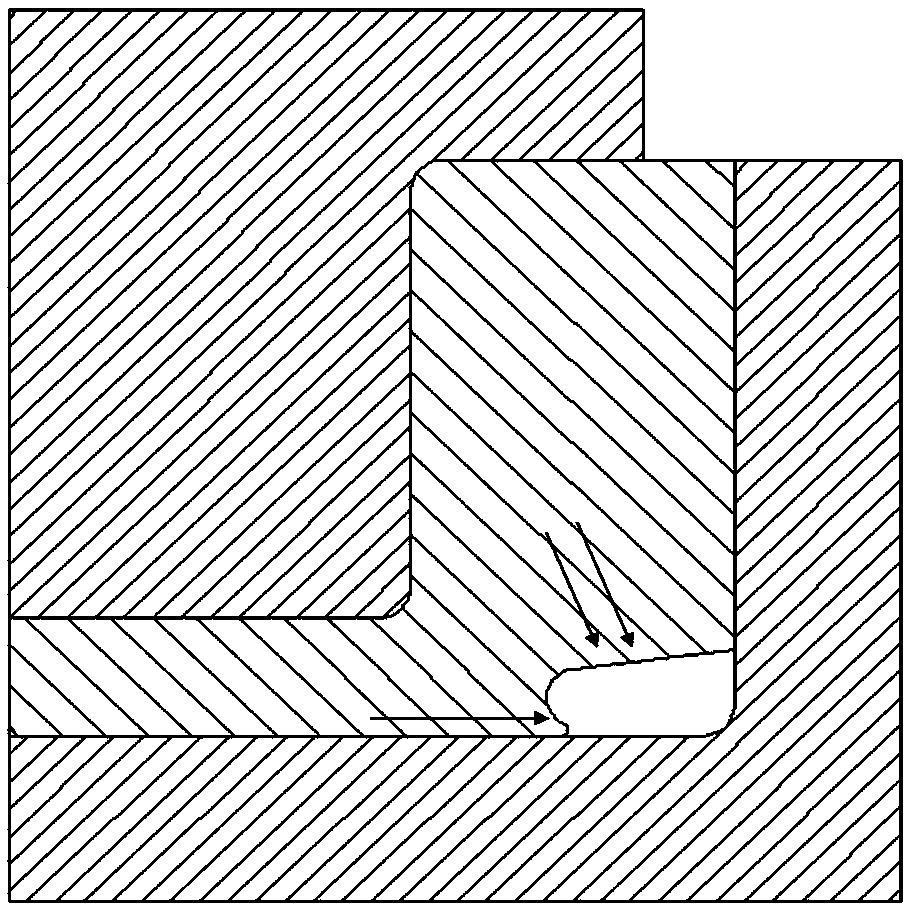

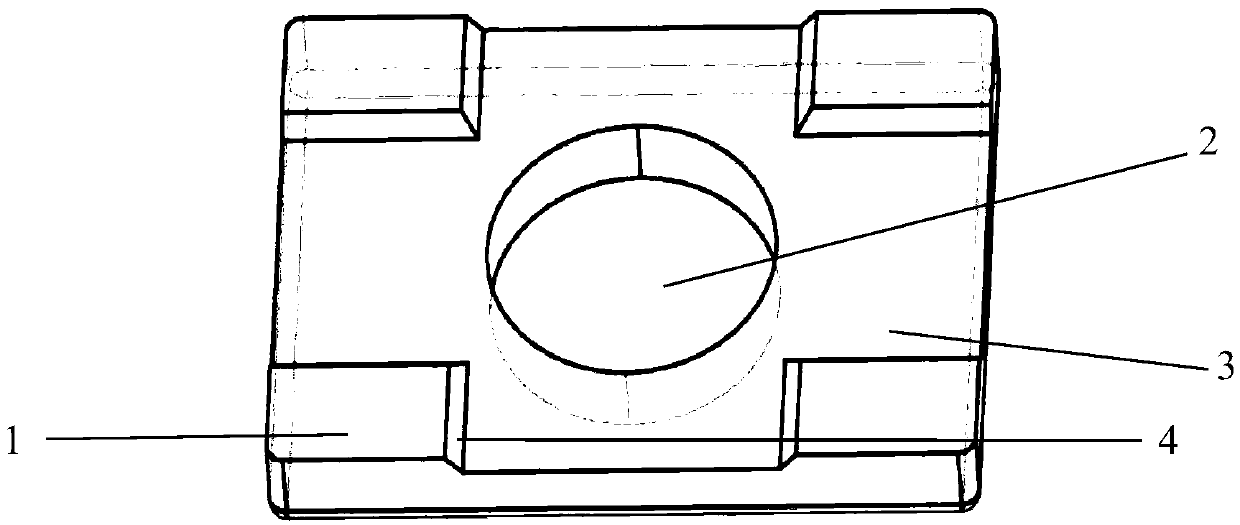

[0040] (1) Billet making: Machine processing the aluminum alloy raw material rolling plate with a thickness of 80mm, and process four bosses on the four corners of the upper surface of the billet. The height of the bosses is 4mm, and the top surface of the bosses is a rectangular plane , the two sides of the boss are perpendicular to the bottom surface, coincide with the side of the blank, and the other two sides transition to the surface of the blank with a slope, the slope angle is 164°, and a through hole with a diameter of 170mm is processed in the middle of the blank, which is corresponding to the through hole than the die. The diameter of the constraining table is 8mm larger to obtain a preform;

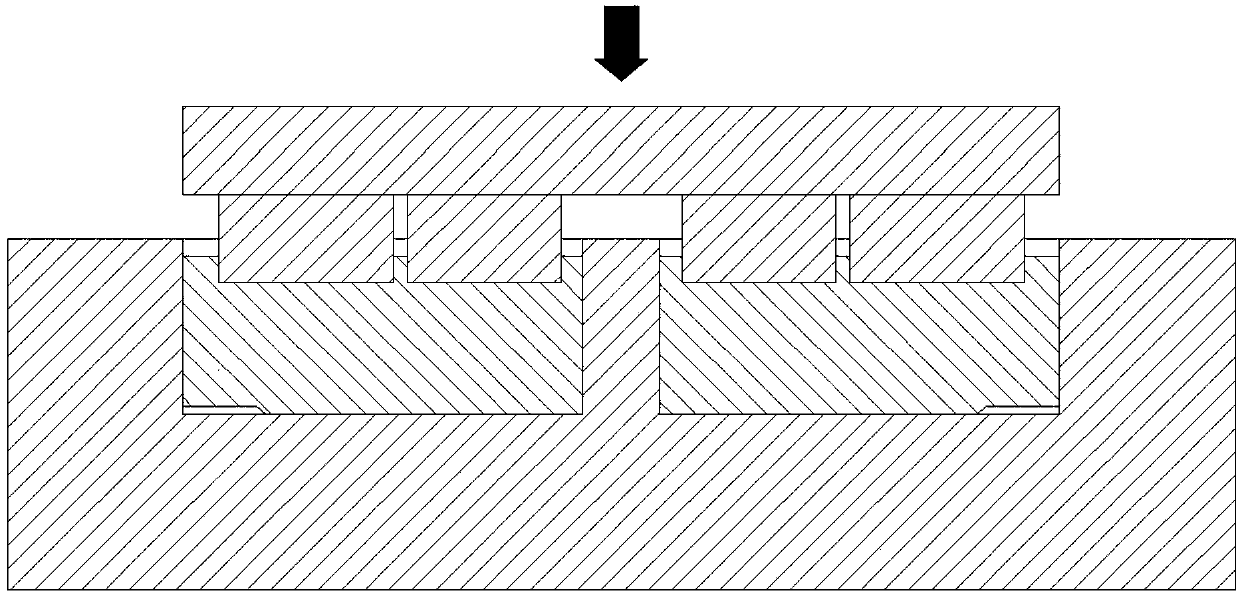

[0041] (2) Forging and forming: Put the obtained aluminum alloy preform into a box-type heating resistance furnace for preheating, take it out when it is heated to 170°C, and spray the graphite emulsion solution evenly on the surface of the blank; the sprayed graphite emulsion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com