Surface sulfur vacancy defect mode structure-enriched sulfur-indium-zinc photocatalyst and preparation method thereof

A photocatalyst and vacancy defect technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problem of high photo-generated electron-hole recombination rate, achieve low cost, simple modification means, improve The effect of photocatalytic hydrogen production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Firstly, the sulfur indium zinc photocatalyst powder was prepared by hydrothermal method, the specific process was as follows: 2 mmol of ZnCl 2 , 4mmol of In(NO 3 ) 3 ·H 2 O and 8 mmol of CH 3 CSNH 2 According to the stoichiometric molar ratio of 1:2:4, it was sequentially dissolved into the aqueous solution, and ultrasonically treated for 30 minutes to prepare a precursor solution; after that, the precursor solution was transferred to a hydrothermal reaction kettle and reacted at 160 degrees for 6 hours; After the reaction, cool to room temperature, collect the reaction product by suction filtration, wash several times with absolute ethanol and deionized water, and dry overnight in a vacuum oven to prepare sulfur indium zinc photocatalyst powder, which is marked as ZIS.

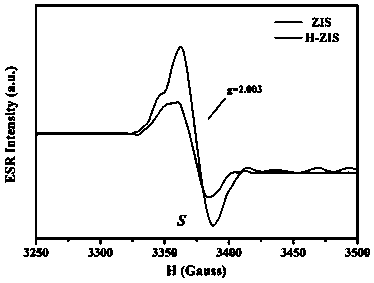

[0020] (2) On the premise of obtaining the above-mentioned sulfur indium zinc photocatalyst powder, further prepare a sulfur indium zinc photocatalyst rich in surface sulfur vacancy defect sta...

Embodiment 2

[0022] (1) The preparation process of the sulfur-indium-zinc photocatalyst powder is the same as in Example 1;

[0023] (2) On the premise of obtaining the above-mentioned sulfur indium zinc photocatalyst powder, further prepare a sulfur indium zinc photocatalyst rich in surface sulfur vacancy defect state structure by means of high temperature and high pressure hydrogenation treatment. The hydrogenation treatment process is specifically: Weigh 0.5 Put 1 gram of sulfur indium zinc photocatalyst powder into the hydrogenation reaction device. After the device is sealed, it is evacuated to below 10 Pa, and then the device is heated to 400 degrees at a heating rate of 10 degrees per minute. Fill high-purity hydrogen (purity greater than 99.999%) until the hydrogen pressure reaches 2.0 MPa; then carry out the hydrogenation reaction for a period of 6 hours under the condition of maintaining 400 degrees and 2.0 MPa high temperature and high pressure; after the reaction is completed, t...

Embodiment 3

[0025] (1) The preparation process of the sulfur-indium-zinc photocatalyst powder is the same as in Example 1;

[0026](2) On the premise of obtaining the above-mentioned sulfur indium zinc photocatalyst powder, further prepare a sulfur indium zinc photocatalyst rich in surface sulfur vacancy defect state structure by means of high temperature and high pressure hydrogenation treatment. The hydrogenation treatment process is as follows: weigh 1.0 Put 1 gram of sulfur indium zinc photocatalyst powder into the hydrogenation reaction device. After the device is sealed, it is evacuated to below 10 Pa, and then the device is heated to 250 degrees at a heating rate of 5 degrees per minute. Fill high-purity hydrogen (purity greater than 99.999%) until the hydrogen pressure reaches 3.0 MPa; then carry out the hydrogenation reaction for a period of 20 hours under the condition of maintaining 250 degrees and 3.0 MPa high temperature and high pressure; after the reaction is over, wait for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com