Dispenser nozzle, manufacturing method thereof, and fluid dispensing device using same

A dispenser and fluid technology, which is applied to the surface coating liquid device, spray device, spray device, etc., can solve the problems of expensive metal precision nozzles, complicated cleaning management, and difficulty in mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, the present invention will be described using the drawings.

[0048] (Dispenser nozzle and manufacturing method thereof)

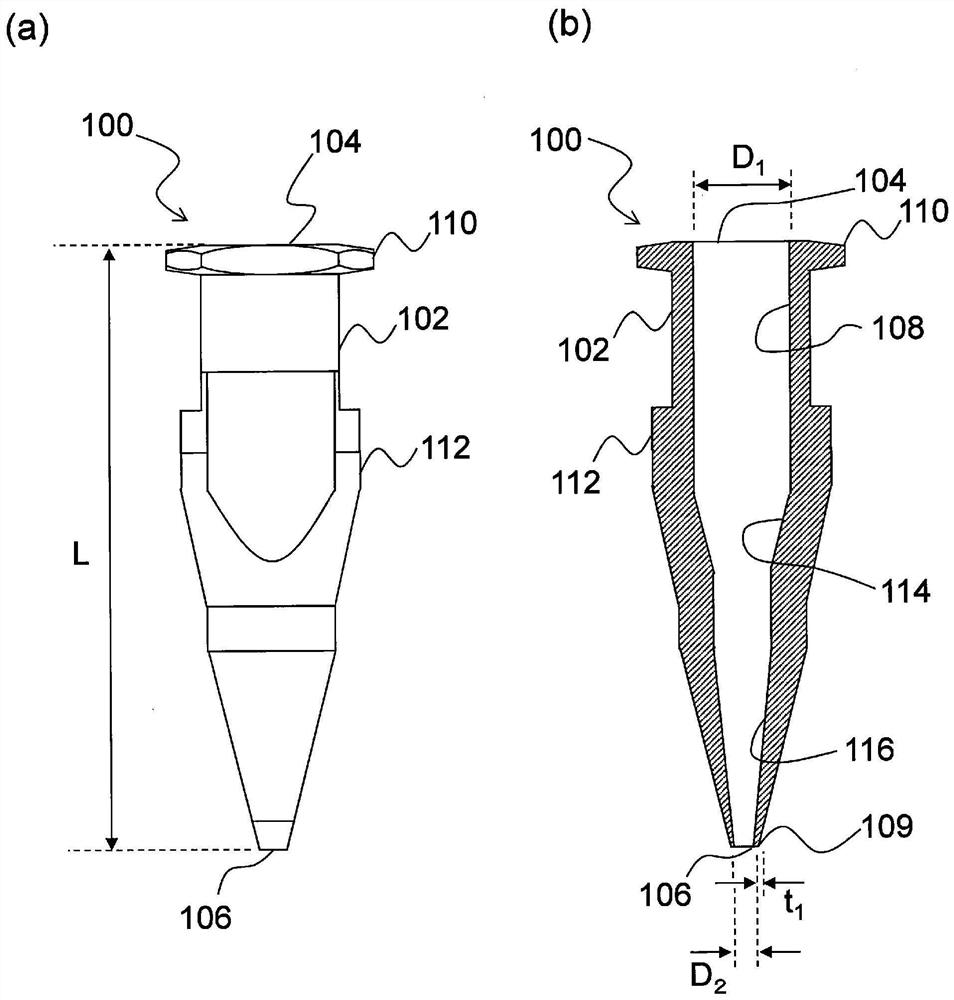

[0049] figure 1 An example of the dispenser nozzle of the present invention is shown. figure 1 (a) is a front view of the dispenser nozzle of the present invention, and (b) is an axial sectional view of the dispenser nozzle.

[0050] The dispenser nozzle 100 consists of a hollow nozzle body 102 . A fluid inlet portion 104 is provided at one end of the nozzle body 102, and a fluid outlet portion 106 is provided at the other end.

[0051] The fluid inlet portion 104 communicates with a fluid supply portion of a fluid dispensing device (not shown), and receives fluid supplied from the fluid supply portion. The fluid inlet portion 104 has, for example, a circular opening shape, and has a structure capable of fitting with a Luer taper. exist figure 1 In the embodiment shown in (a), the flange 110 is provided above the nozzle body 102, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com