Novel outer conductor embossing mould of super-flexible 1/2 feeder line cable, and method thereof

A technology of outer conductor and embossing, which is used in the manufacture of cables/conductors and used to form corrugations and circuits on conductors/cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

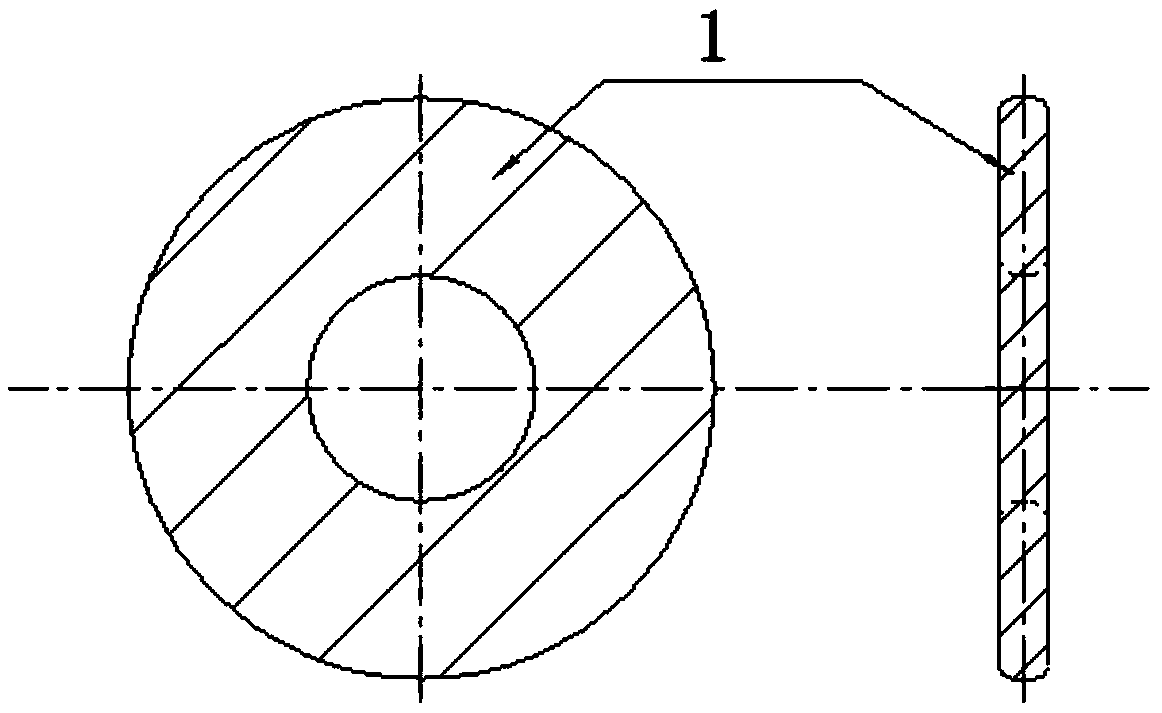

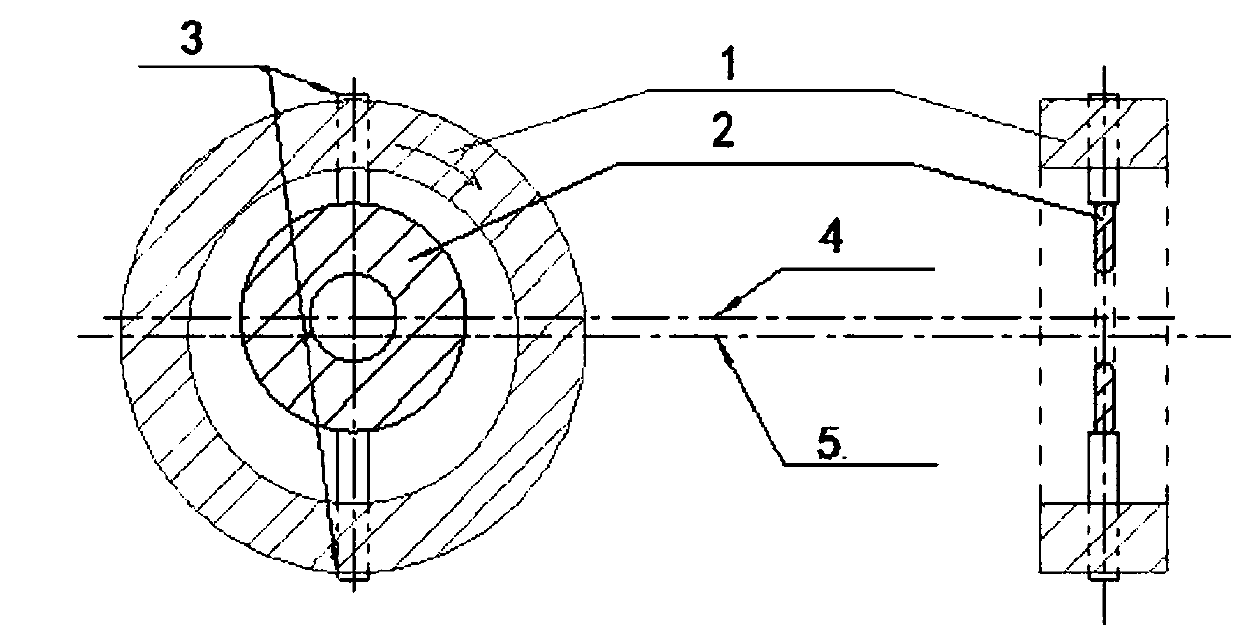

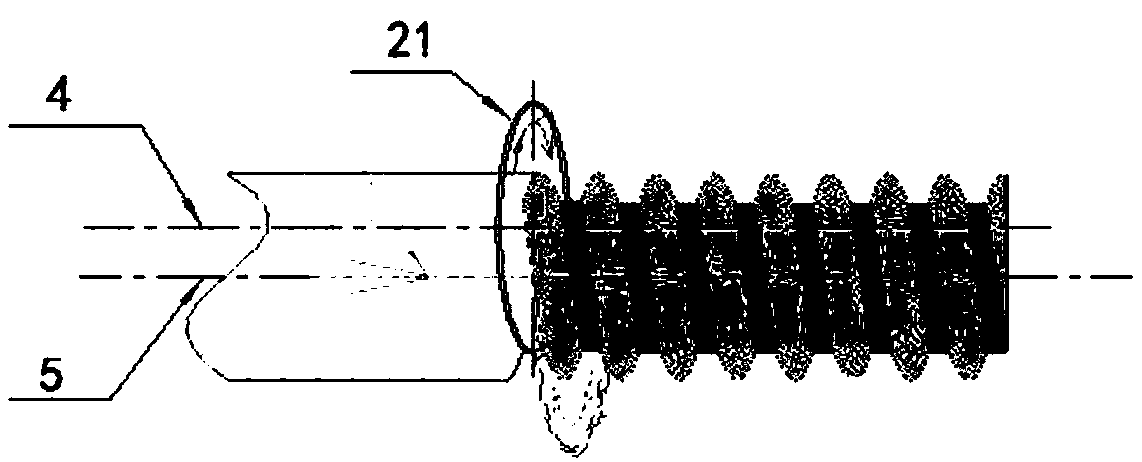

[0036] Such as figure 1 , 2 , 3, a new type of outer conductor embossing die for super flexible 1 / 2 "feeder cable, including a concentrically rotating embossing head 1, said embossing head 1 is provided with an embossing ring 2, said embossing The ring center line 4 is not the same line as the embossing head center line 5, wherein the embossing ring center line 5 coincides with the cable outer conductor center line. That is, compared with the prior art, the embossing ring and the embossing head are concentric Setting, the eccentric setting of the embossing in this embodiment can realize the adjustable trough of the embossing, that is, adjust the eccentricity of the embossing ring 2 and the new outer conductor, and at the same time, the pitch of the embossing in this embodiment can also be adjusted, that is, through Adjust the embossing ratio to realize the adjustment of the embossing pitch. The embossing ratio refers to the ratio between the production speed of the new outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com