A mechanical automatic structure demonstration teaching device

A technology of automatic structure and teaching device, applied in the field of teaching tools, can solve problems such as students being difficult to understand and teachers being laborious in explaining, etc., to achieve the effect of intuitive display, novel design and convenient learning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

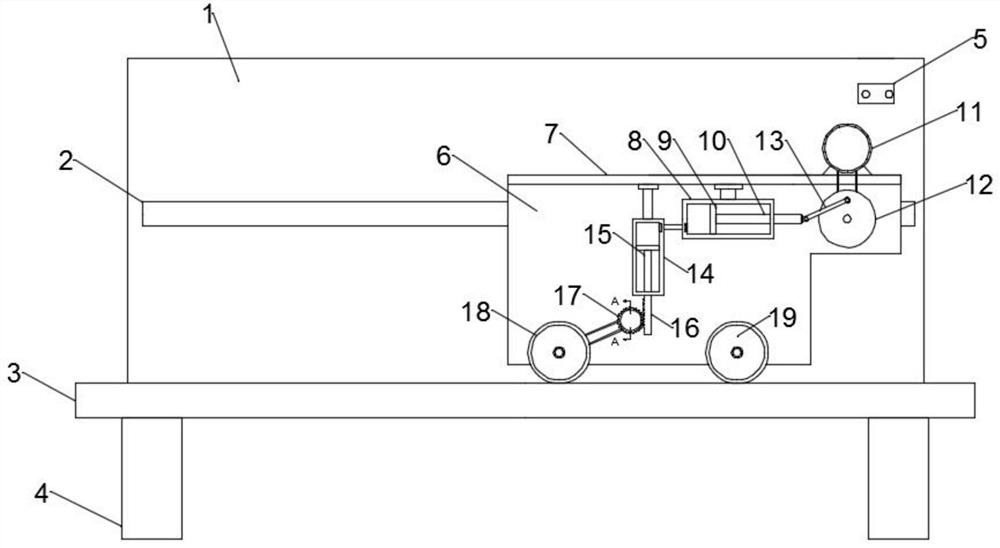

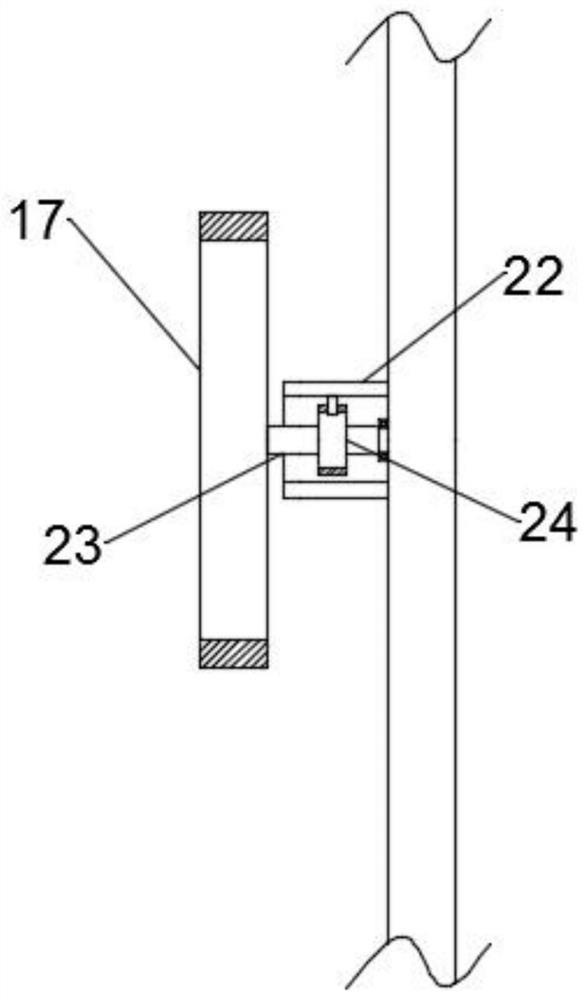

[0027] In the embodiment of the present invention, a mechanical automatic structure demonstration teaching device includes a base plate 3, a vertical plate 1 fixed on the base plate 3 and perpendicular to the base plate 3, and a sliding plate 6; the lower end of the base plate 3 is symmetrically equipped with legs 4 , the legs 4 play a supporting role, the rear end of the sliding plate 6 is fixed with a slider, and the slider is slidably connected with the slide rail 2 arranged at the front end of the vertical plate 1, so that the sliding plate 6 can be horizontally positioned relative to the vertical plate 1 direction, the upper end of the sliding plate 6 is fixed with a receiving plate 7 for installing the motor 11, the receiving plate 7 is placed horizontally and perpendicular to the sliding plate 6, and the lower end of the sliding plate 6 is provided with a pneumatic mechanism driven by the motor 11. The mechanism communicates with the sealing cylinder 14 through a communi...

Embodiment 2

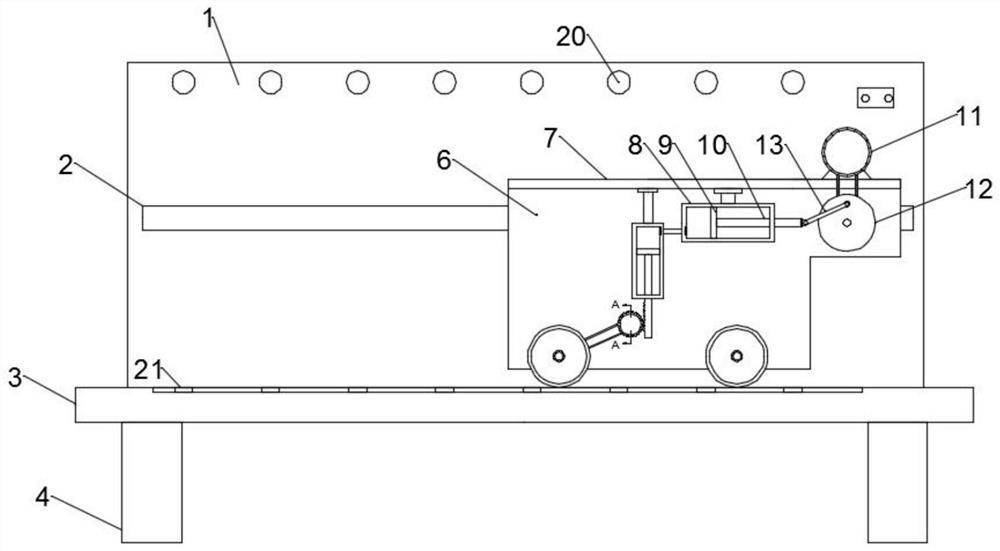

[0034] In the embodiment of the present invention, a mechanical automatic structure demonstration teaching device includes a base plate 3, a vertical plate 1 fixed on the base plate 3 and perpendicular to the base plate 3, and a sliding plate 6; the lower end of the base plate 3 is symmetrically equipped with legs 4 , the legs 4 play a supporting role, the rear end of the sliding plate 6 is fixed with a slider, and the slider is slidably connected with the slide rail 2 arranged at the front end of the vertical plate 1, so that the sliding plate 6 can be horizontally positioned relative to the vertical plate 1 direction, the upper end of the sliding plate 6 is fixed with a receiving plate 7 for installing the motor 11, the receiving plate 7 is placed horizontally and perpendicular to the sliding plate 6, and the lower end of the sliding plate 6 is provided with a pneumatic mechanism driven by the motor 11. The mechanism communicates with the sealing cylinder 14 through a communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com