A thermal fusion effect pile end stiffness adjustment device

An adjustment device and hot-melt technology, applied in construction, infrastructure engineering and other directions, can solve the problems of short circuit, support stiffness cannot be actively intervened and adjusted according to needs, etc., to achieve simple process steps, flexible and convenient control and adjustment, and easy to achieve. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

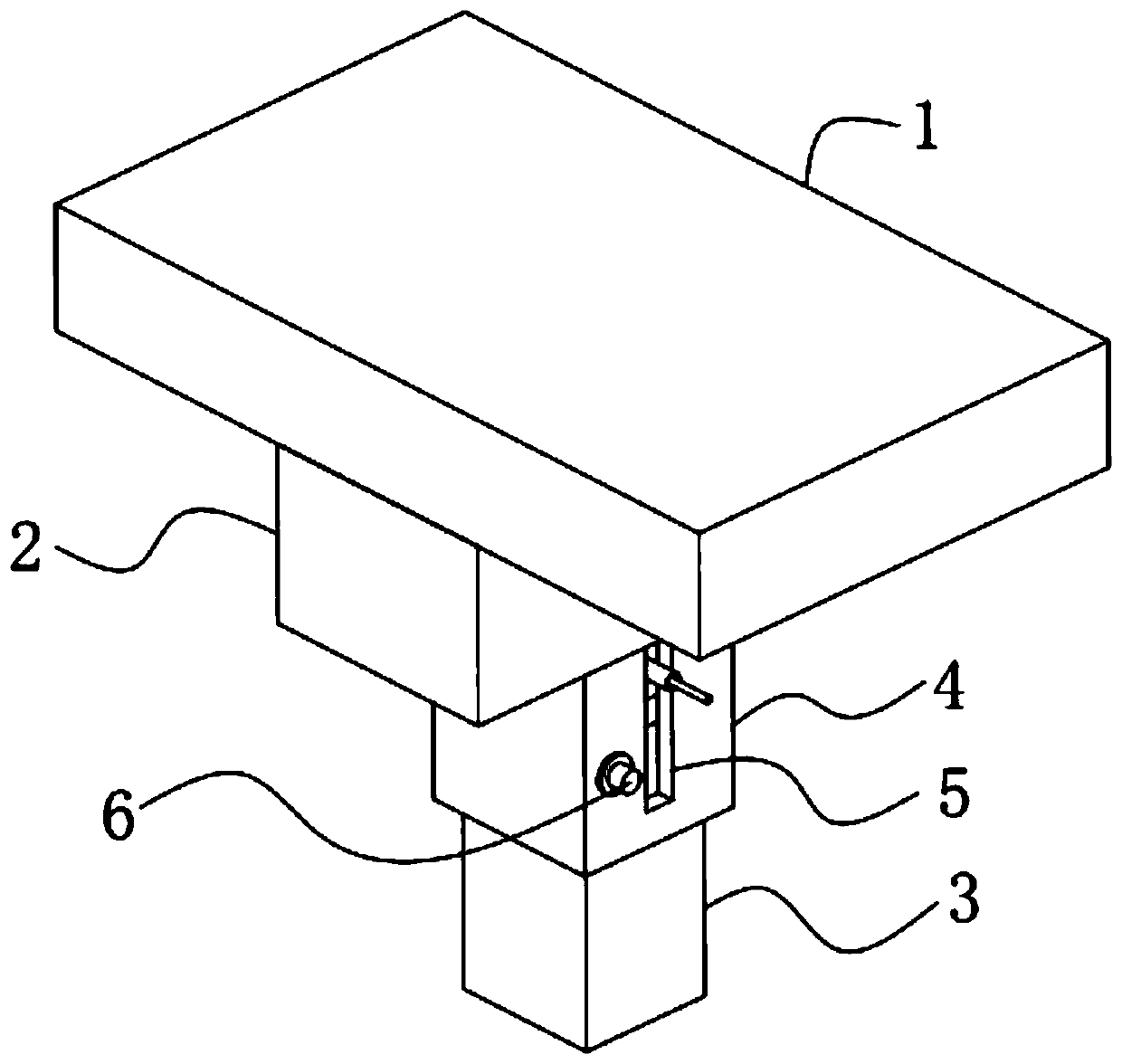

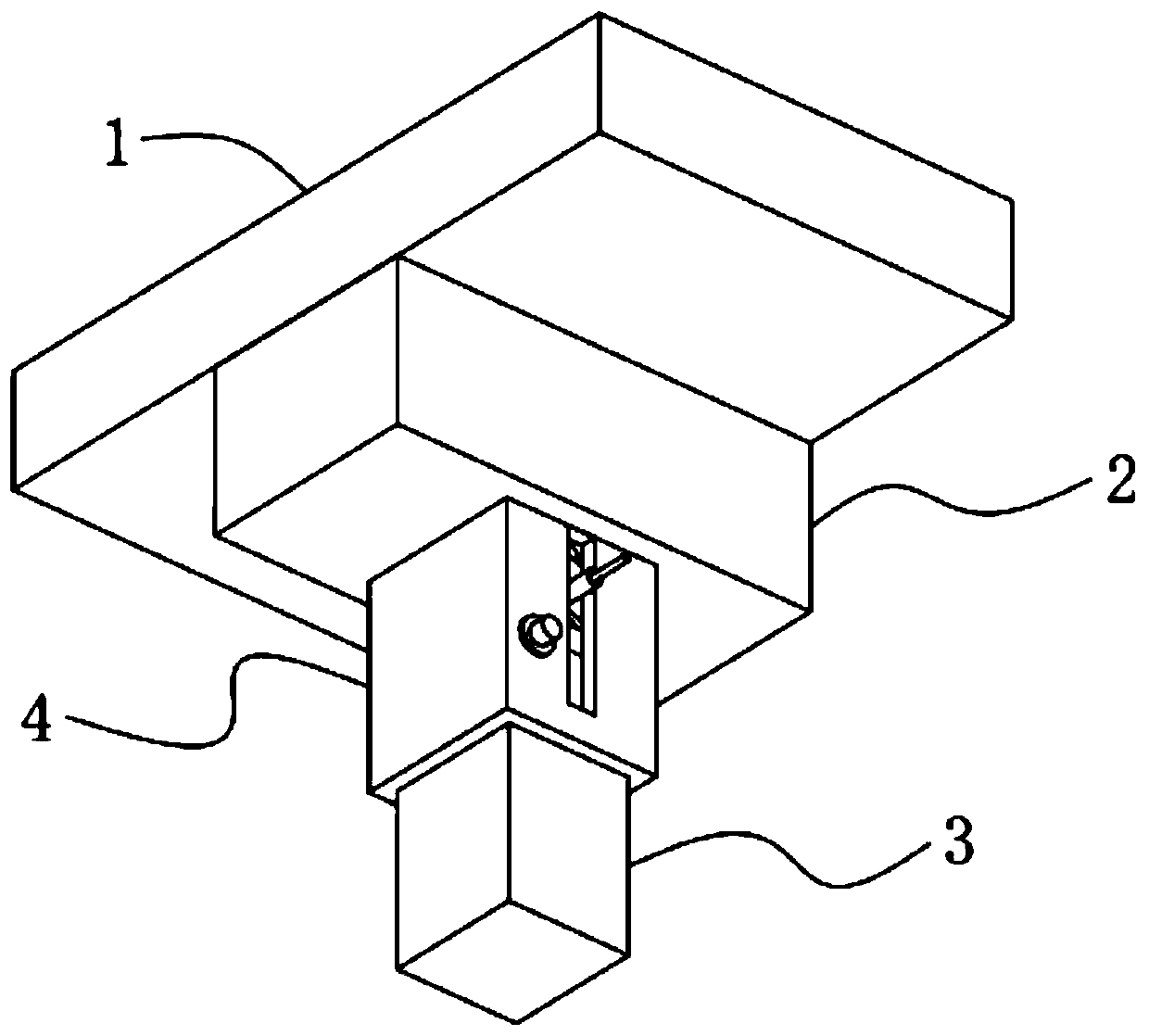

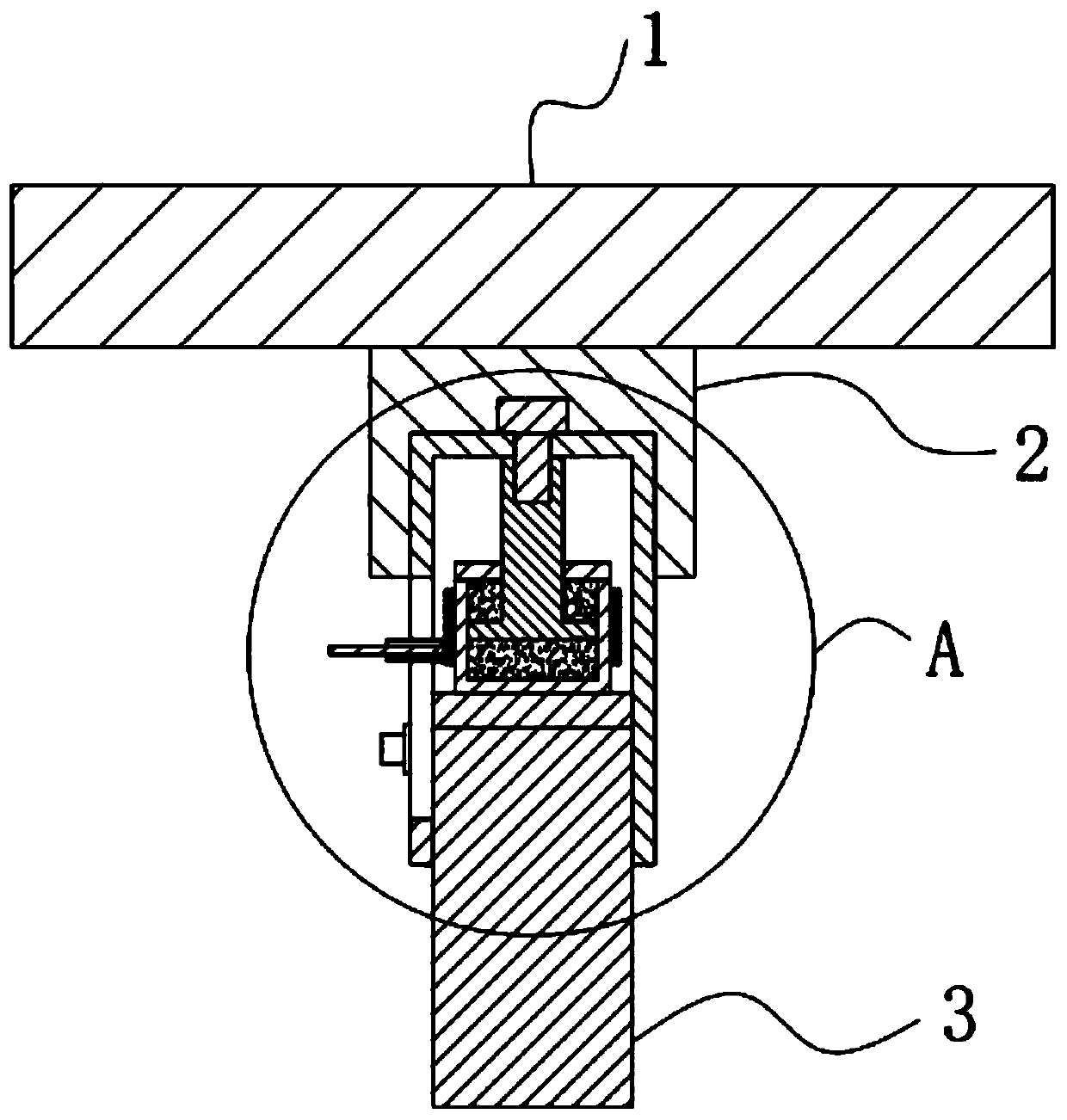

[0047] A thermal fusion effect pile end stiffness adjustment device, such as figure 1 , 2 , 5 and 6, including a raft 1 and a pile body 3 fixedly installed on the pile foundation, the bottom of the raft 1 is poured with a ground beam 2, and the bottom of the ground beam 2 is reserved with an installation groove 12, The inside of the mounting groove 12 is fixed with a cylinder 4, the top of the cylinder 4 is a closed structure, and the bottom of the cylinder 4 is an open structure, and the upper end of the pile 3 is movably inserted in the cylinder. Inside the bottom of the body 4, and the upper end of the pile body 3 is fixedly installed with a top plate 11, and a heat-melt telescopic element 10 is arranged between the top of the top plate 11 and the inner top wall of the cylinder body 4.

[0048] The hot-melt telescopic element 10 effectively uses the hot-melt effect to change its telescopic height to further improve the existing pile end stiffness adjustment device, so as t...

Embodiment 2

[0065] The difference from Example 1 is that a protective layer is also provided on the surface of the electromagnetic heating coil 20, and the protective layer is prepared by the following method:

[0066] Take the following raw materials and weigh them by weight: 20 parts of ceramic particles, 8 parts of alumina powder, 12 parts of silicon nitride, 18 parts of polyethylene, 10 parts of vinyl acetate, 11 parts of acrylic emulsion, 10 parts of phenolic resin, ten parts of alcohol ester 2 parts of diethylthiourea, 2 parts of diethylthiourea, 1 part of high-carbon alcohol fatty acid ester compound, 3 parts of polydimethylsiloxane, 1 part of organic bentonite and 30 parts of ethanol;

[0067] S1. Add the weighed acrylic emulsion, alcohol ester dodeca, diethylthiourea, higher alcohol fatty acid ester complex, polydimethylsiloxane and ethanol into the mixer and stir for 25min at a stirring speed of 500r / min, make mixed solution;

Embodiment 3

[0074] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0075] Take the following raw materials and weigh them by weight: 25 parts of ceramic particles, 10 parts of alumina powder, 14 parts of silicon nitride, 23 parts of polyethylene, 11 parts of vinyl acetate, 13 parts of acrylic emulsion, 11 parts of phenolic resin, ten parts of alcohol ester 3 parts of diethylthiourea, 3 parts of diethylthiourea, 2 parts of high-carbon alcohol fatty acid ester complex, 4 parts of polydimethylsiloxane, 2 parts of organic bentonite and 40 parts of ethanol;

[0076] S1. Add the weighed acrylic emulsion, alcohol ester dodeca, diethylthiourea, higher alcohol fatty acid ester complex, polydimethylsiloxane and ethanol into the mixer and stir for 30min at a stirring speed of 600r / min, make mixed solution;

[0077] S2. Add organic bentonite, ceramic particles, calcium carbonate powder, silicon nitride, polyethylene, viny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com