Novel production process for silk spinning

A production process, a new type of technology, applied in silk fiber production, textiles and papermaking, fiber cutting, etc., can solve the problems that automatic silk spinning has not made a major breakthrough, and achieve the improvement of overall product quality, low accident rate, and simplification of the overall process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0049] The invention provides a new production process for silk spinning, which adopts a fully automated method to replace the original silk spinning production process, and makes a breakthrough by changing the original circular comb method with low utilization rate into a straight comb method with higher effect, so that the whole process The simplified process can realize fully automatic production, thereby greatly reducing the number of operators, improving safety, and ensuring high fiber uniformity after production, greatly improving product quality.

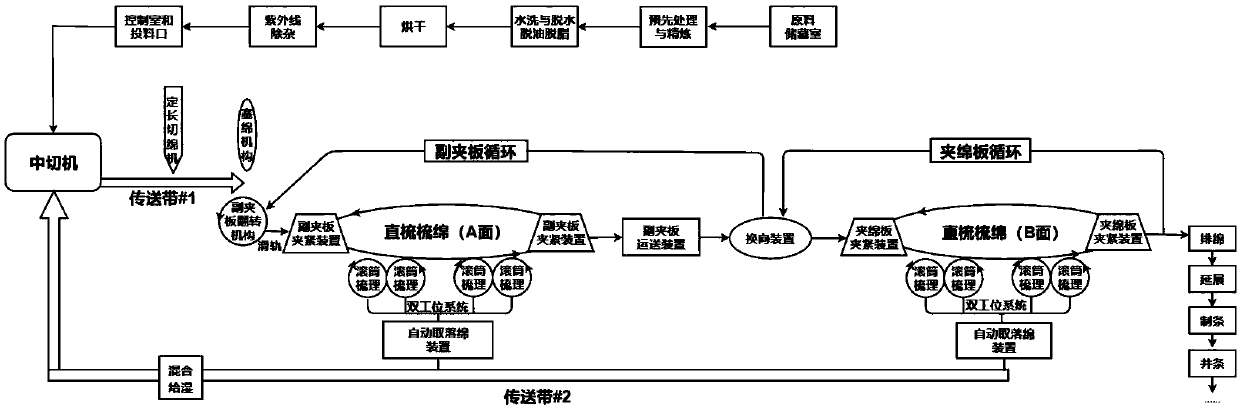

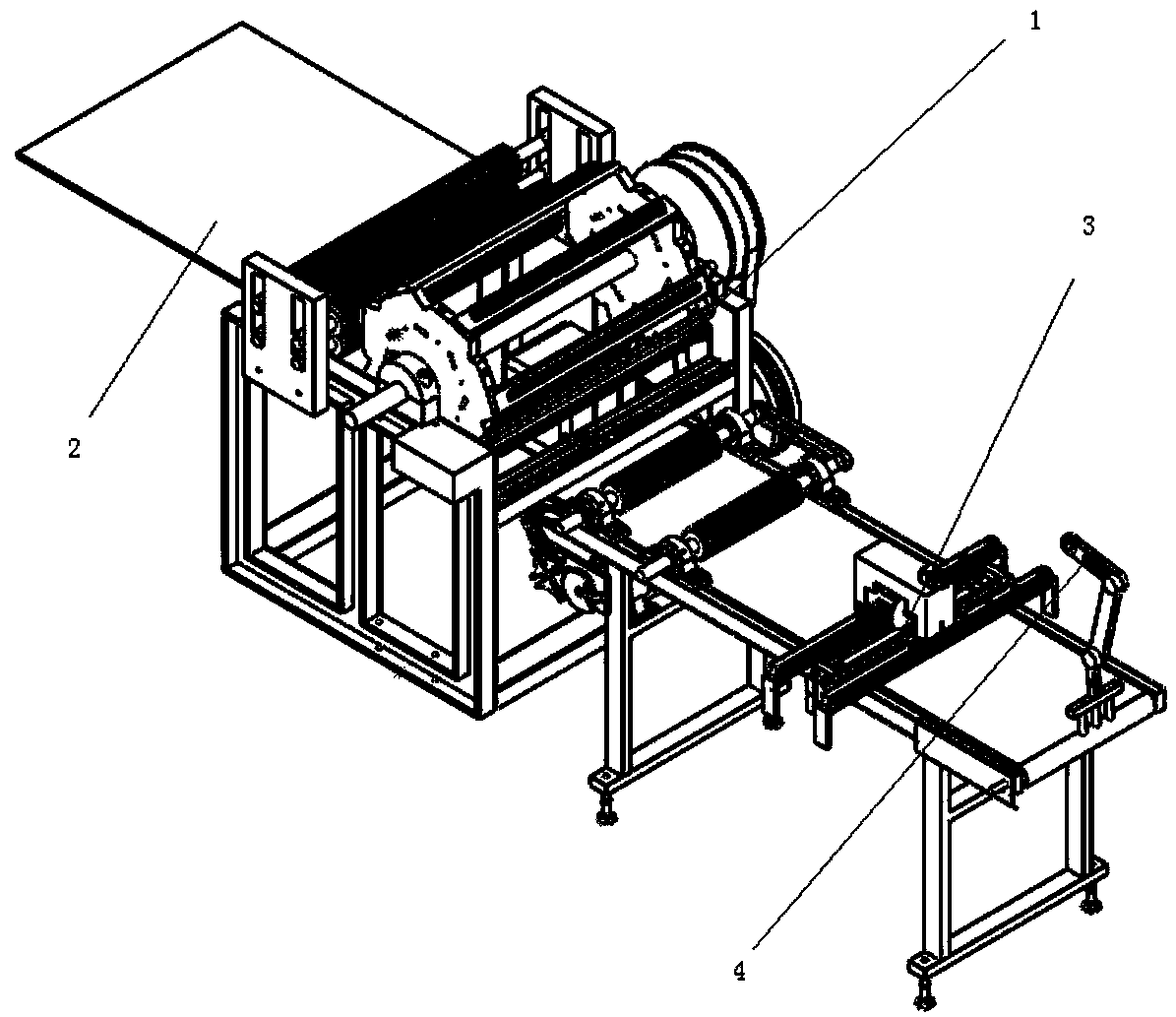

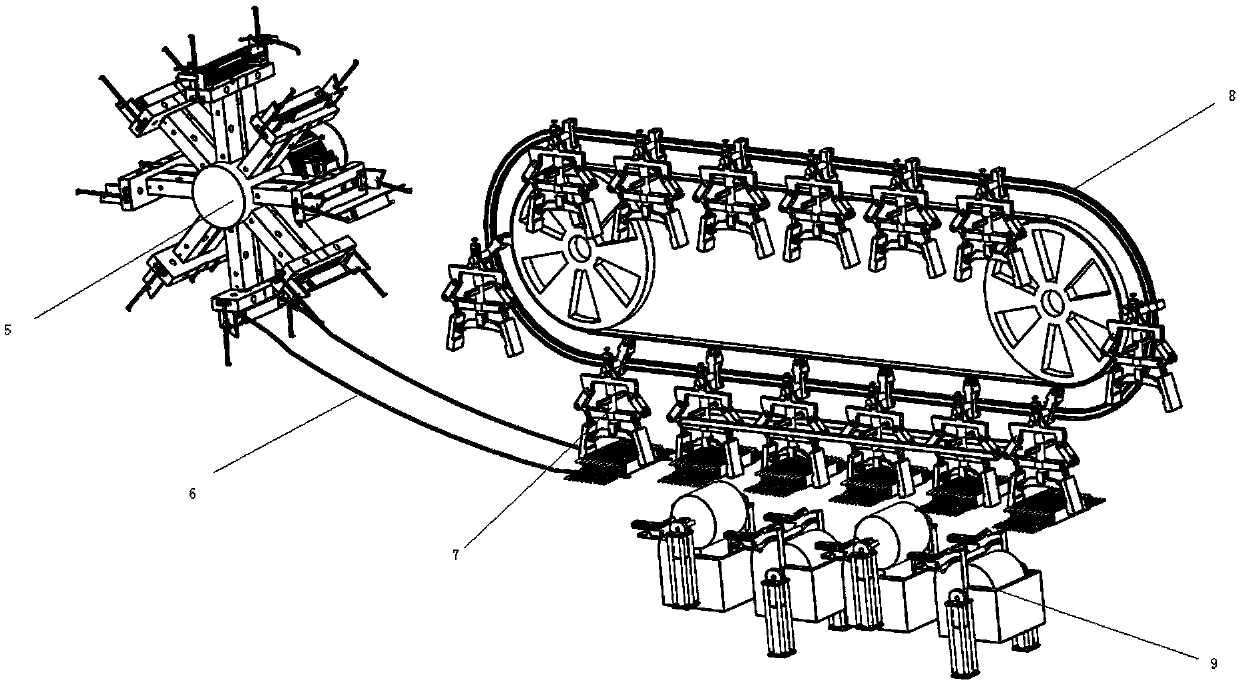

[0050] As a specific embodiment of the present invention, the present invention provides such as figure 1 Shown is a novel production process for silk spinning, and the equipment used for the production process is as follows: Figure 2-7 Shown includes center cutting machine 1, transmission be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com