Vibration aging method for lowering and homogenizing residual stress generated after turnout switch rail quenching

A residual stress and vibration aging technology, used in design optimization/simulation, special data processing applications, instruments, etc., can solve the problem of inability to accurately locate the point with the smallest displacement deformation and the most displacement deformation, affect the residual stress elimination effect, and obtain residual stress. It can achieve the effect of eliminating residual stress, short time and good residual stress without reducing the problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: This embodiment specifically relates to a vibration aging method for reducing and homogenizing the residual stress of the switch point rail after quenching. By performing modal analysis on the finite element model of the point rail of the switch point, accurate fixed support points and exciting vibrations are obtained. Point, and get the best actual excitation force and actual excitation frequency, and then carry out vibration aging on the switch point rail, effectively reduce the overall residual stress of the switch point rail after quenching.

[0022] In this embodiment, the vibration aging method for reducing and homogenizing the residual stress of the switch point rail after quenching includes the following steps: Step 1: Establish a finite element model of the switch point rail, and simulate the quenching process according to the finite element model to obtain the quenching completion The residual stress distribution cloud diagram of the switch point ...

Embodiment 2

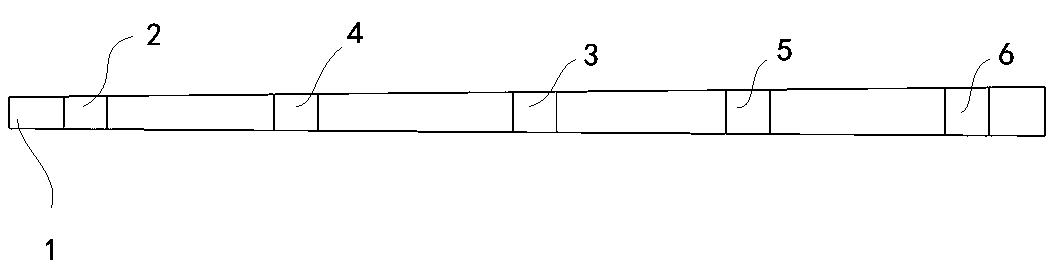

[0029] Embodiment two: if figure 1 As shown, this embodiment specifically relates to a vibration aging method for reducing and homogenizing the residual stress after quenching of the 50AT type switch point rail. Residual Stress.

[0030]Firstly, a finite element model is constructed for the 50AT switch point rail, and the residual stress distribution cloud map is obtained by simulating the quenching process of the 50AT type switch point rail through the finite element model.

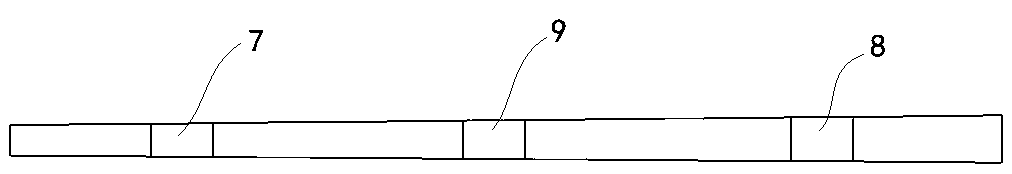

[0031] Then, the free modal analysis is carried out on the finite element model, and the tenth-order free modal vibration diagram of the 50AT switch point rail is obtained, in which there are three positions with small displacement and deformation, and the above-mentioned position points are determined as fixed supports point. Such as figure 1 As shown, taking the bottom of tip 1 of the 50AT type turnout point rail as the origin, the first fixed support point 2 is 700mm away from the origin, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com