Fastener quenching treatment equipment

A technology for processing equipment and fasteners, which is applied to heat treatment equipment, quenching devices, heat treatment furnaces, etc., can solve problems such as cracking, excessive deformation, and parts that do not meet the predetermined requirements, so as to achieve uniform contact, improve production efficiency, Effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

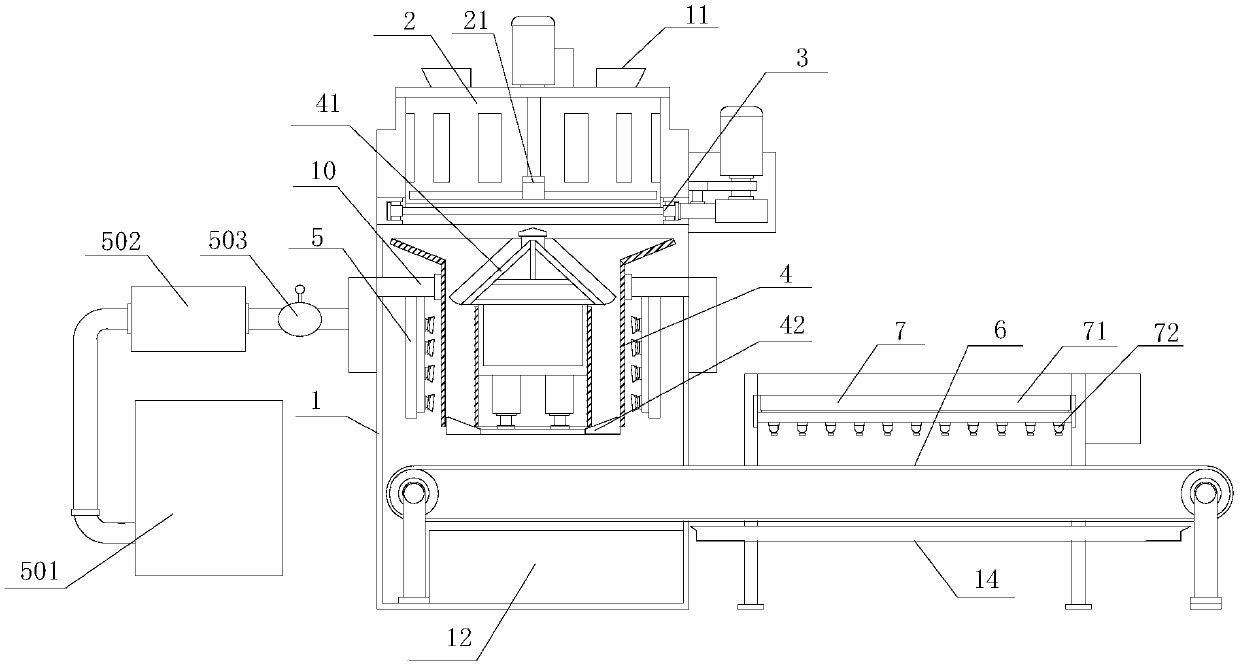

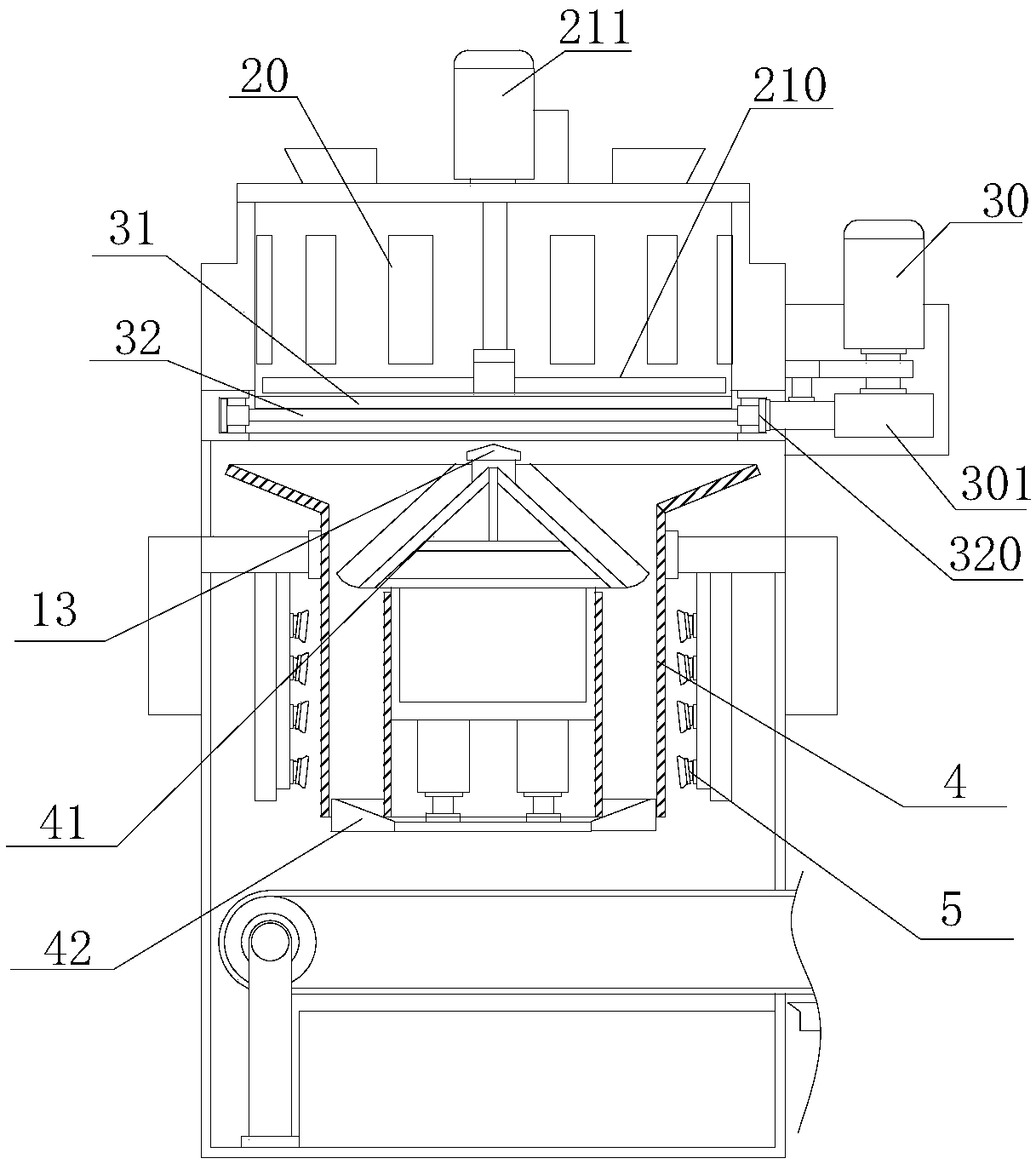

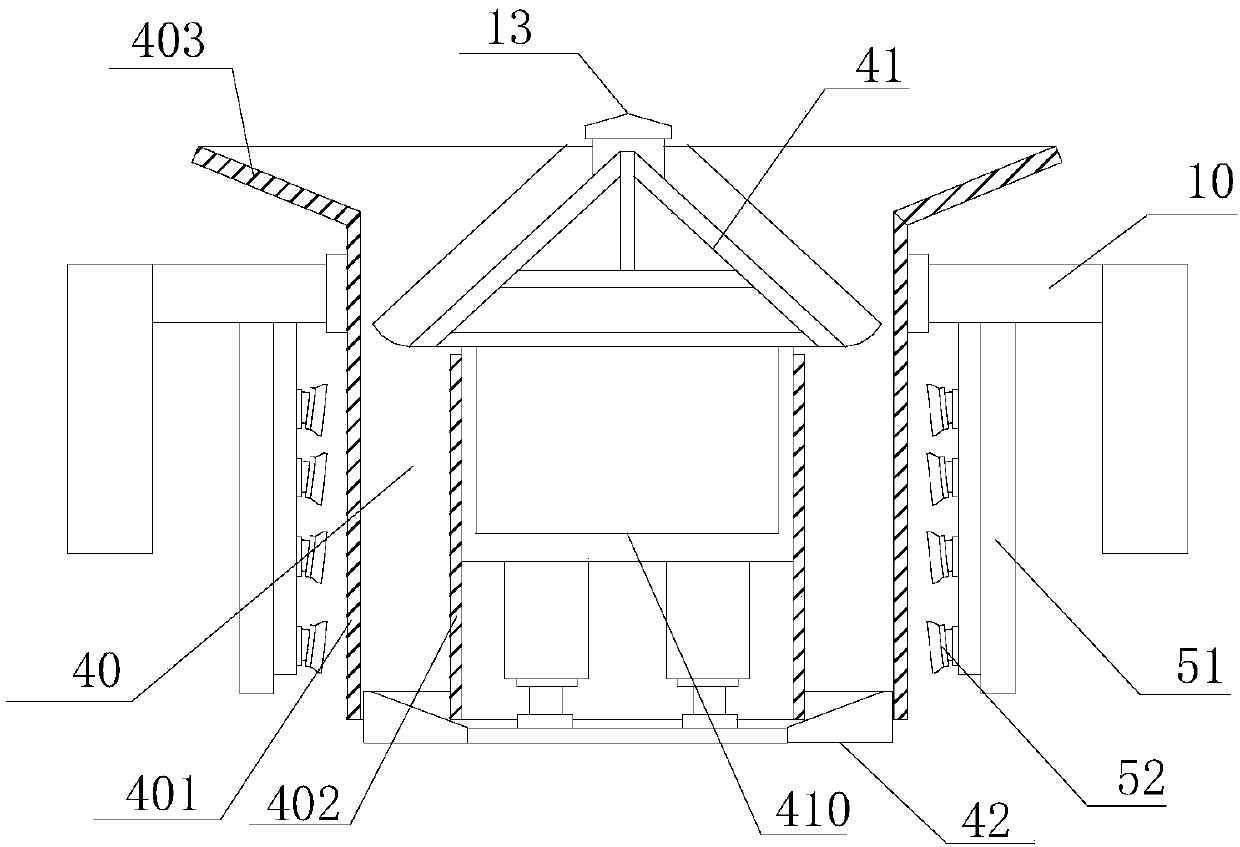

[0020] refer to Figure 1 to Figure 7 A fastener quenching treatment device of the present invention comprises a frame 1, a heating chamber 2, a first blanking device 3, a quenching box 4, a cooling spray device 5, a conveying device 6 and a blast drying device 7, the machine A heating chamber 2, a first unloading device 3, a quenching box 4, and a first waste liquid recovery box 12 are sequentially arranged in the frame 1 from top to bottom. The upper part of the frame 1 is provided with a plurality of chambers communicating with the heating chamber 2. The feeding port 11, the inner wall of the heating chamber 2 are evenly distributed with heating components 20, the first unloading device 3 is installed at the bottom of the heating chamber 2, and the quenching box 4 includes an outer cylinder 401 and an inner cylinder 402 , the top of the inner cylinder 402 is provided with a distributing mechanism 41, a material chamber 40 is formed between the outer cylinder 401 and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com