Molding sand dispersing and screening device for mechanical casting

A technology of mechanical casting and screening device, which is applied in casting molding equipment, machinery for cleaning/processing mold materials, and manufacturing tools, etc. The effect of accelerated screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

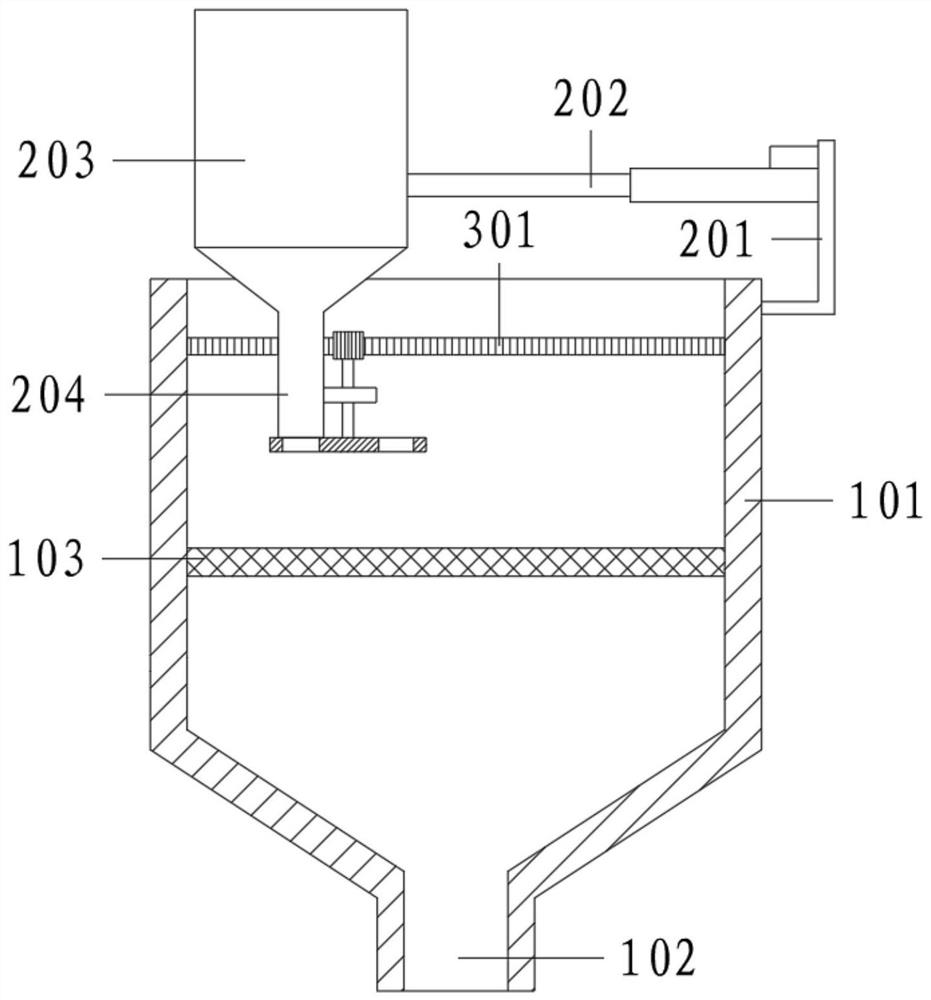

[0036] See attached figure 1 , a molding sand dispersion and screening device for mechanical casting, comprising a screening cylinder 101, a feed box 203, a screen 103 and a feeding mechanism,

[0037] The screen 103 is installed in the middle of the screening cylinder 101, and the bottom is provided with a discharge port 102; a support 201 is connected to one side of the top of the screening cylinder 101, and an electric push rod 202 is installed on the support 201; one end of the electric push rod 202 is connected to the support 201, and the other is One end extends to the other side of the top and is connected with a material box 203; the bottom of the material box 203 is connected with a feeding pipe 204, and one side of the feeding pipe 204 is connected with a support 205;

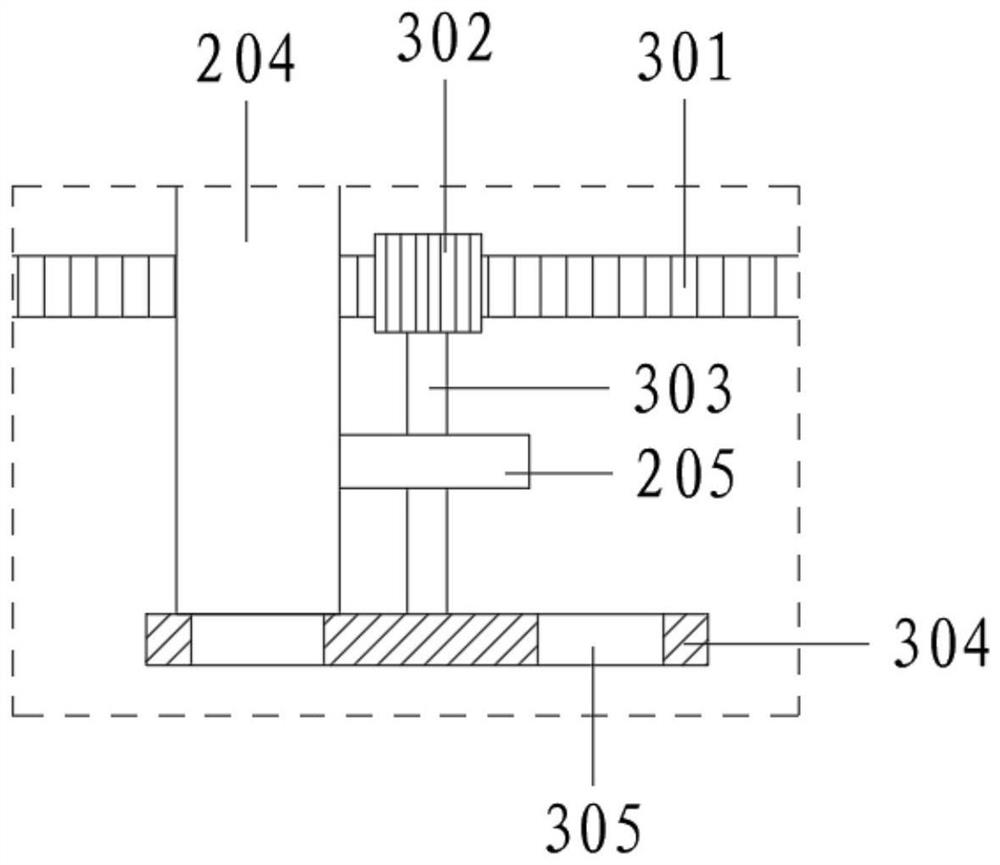

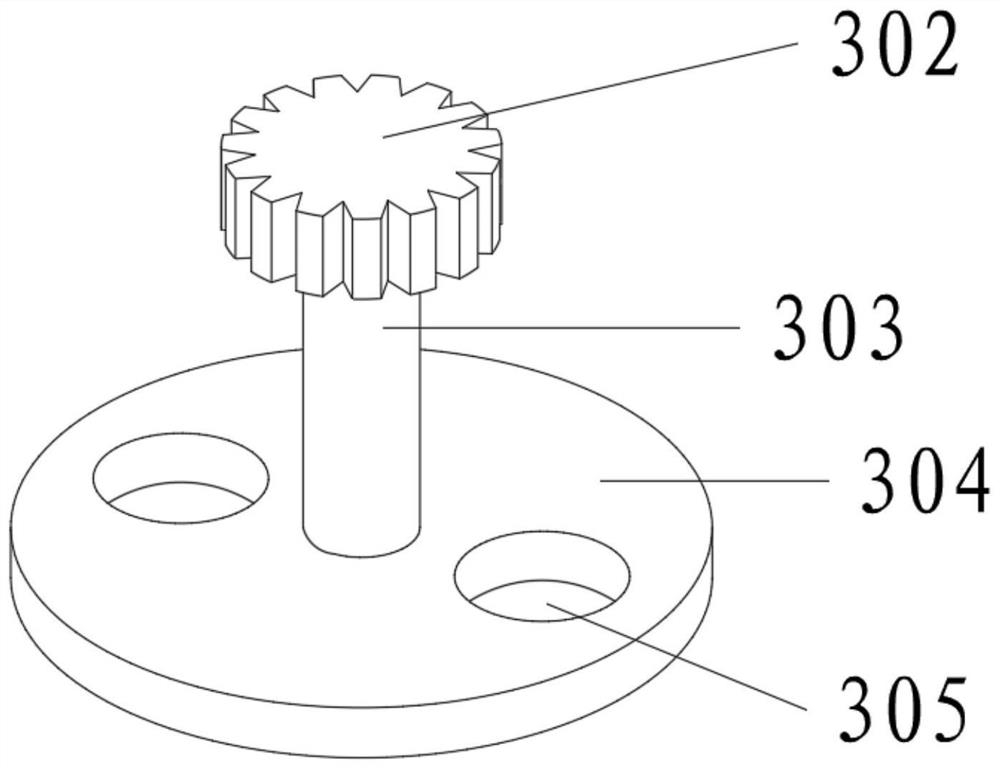

[0038] See attached figure 2 , 3 , the blanking mechanism includes a fixed rack 301, a gear 302, a connecting shaft 303 and a turntable 304, the fixed rack 301 is fixedly connected to the upper par...

Embodiment 2

[0042] On the basis of embodiment 1,

[0043] See attached Figure 4 , 5 , the edge of the top surface of the screen 103 is upwardly connected with a guide rod 104, the inner wall of the screening cylinder 101 is connected with a fixed plate 105, and the guide rod 104 passes through the fixed plate 105; a driven shaft 402 is arranged below the screen 103, and the driven shaft 402 There is a cam 401 which bears against the screen 103 .

[0044] One end of the driven shaft 402 stretches out the screening cylinder 101 and is equipped with the No. 2 gear 403; the No. 2 gear 403 is meshed with a longitudinal mobile rack 503, and the top of the mobile rack 503 is connected with a stay rope 502; the top of the screening cylinder 101 is equipped with The guide wheel 501 and the stay rope 502 go around the guide wheel 501 and are connected with the magazine 203 .

[0045] The outer wall of the screening cylinder 101 is also fixedly connected with a longitudinal slide rail 505 , on w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com