Multi-substrate alignment printing method and alignment printing machine

A technology of alignment printing and printing machines, which is applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of no re-inspection, low efficiency, and difficulty in ensuring alignment accuracy, so as to ensure quality and ensure efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

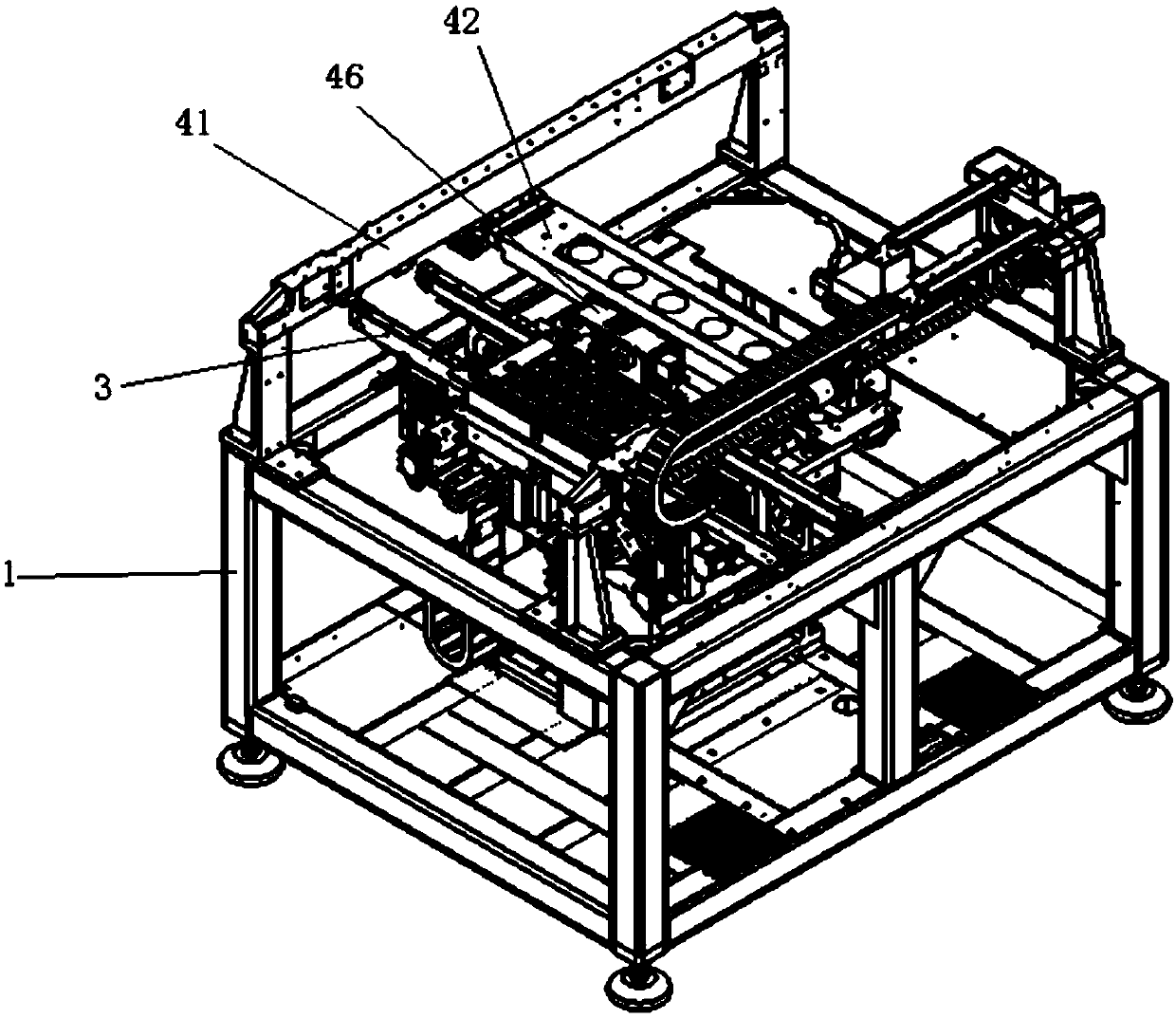

[0031] The following further describes the present invention based on the drawings and specific embodiments, but the implementation of the present invention is not limited thereto.

[0032] A multi-substrate alignment printing method includes the following steps:

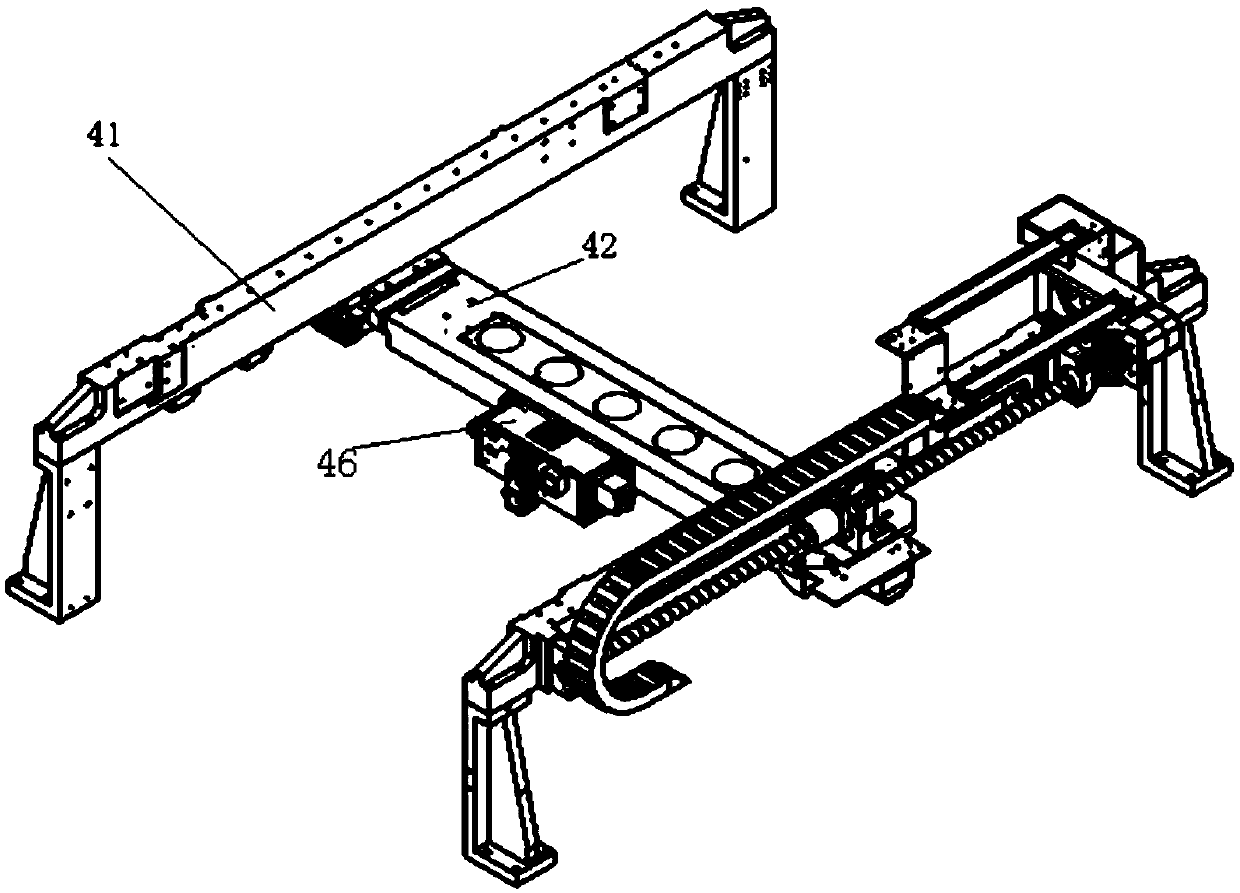

[0033] (1) Multi-substrate transportation; the jig loaded with multiple substrates is transported to the printing position of the printer through the transportation rail, and the transportation rail stops the transportation of the jig;

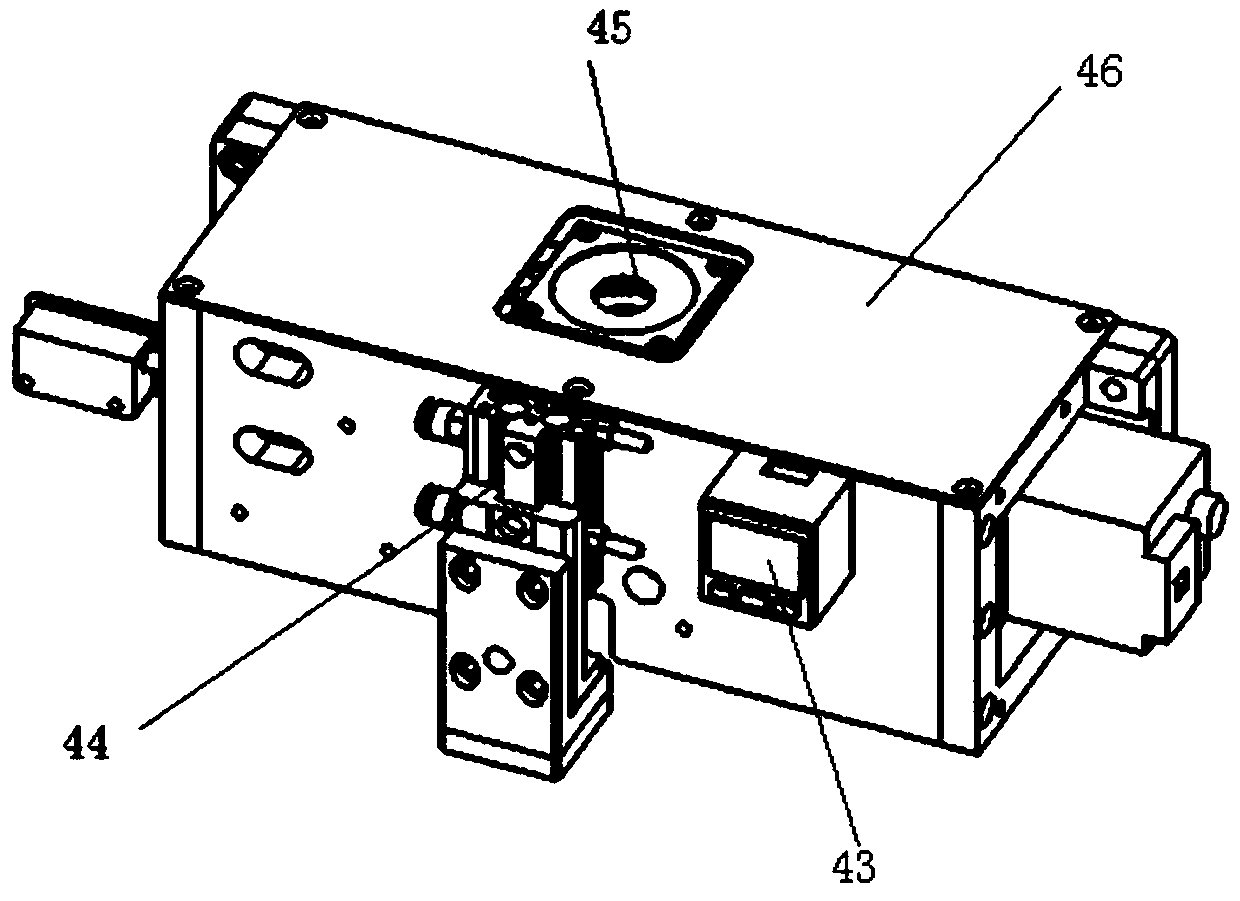

[0034] (2) The CCD module corrects the coincidence of the steel mesh and the fixture MARK; the CCD module first calibrates the coincidence of the steel mesh and the fixture MARK, and then positions each individual substrate MARK, and starts the correction after the positioning is completed;

[0035] (3) Substrate calibration; the lower nozzle platform is lifted and sucked the substrate by the lifting mechanism; the lower nozzle platform is provided with the same number of lower nozzles as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com