Injection mold for side gate vertical runners and side gates

A side gate and vertical flow technology, which is applied in the field of side gate vertical runners and side gate plastic molds, can solve problems such as product structure complexity, improve material utilization, shorten alignment, and ensure processing effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

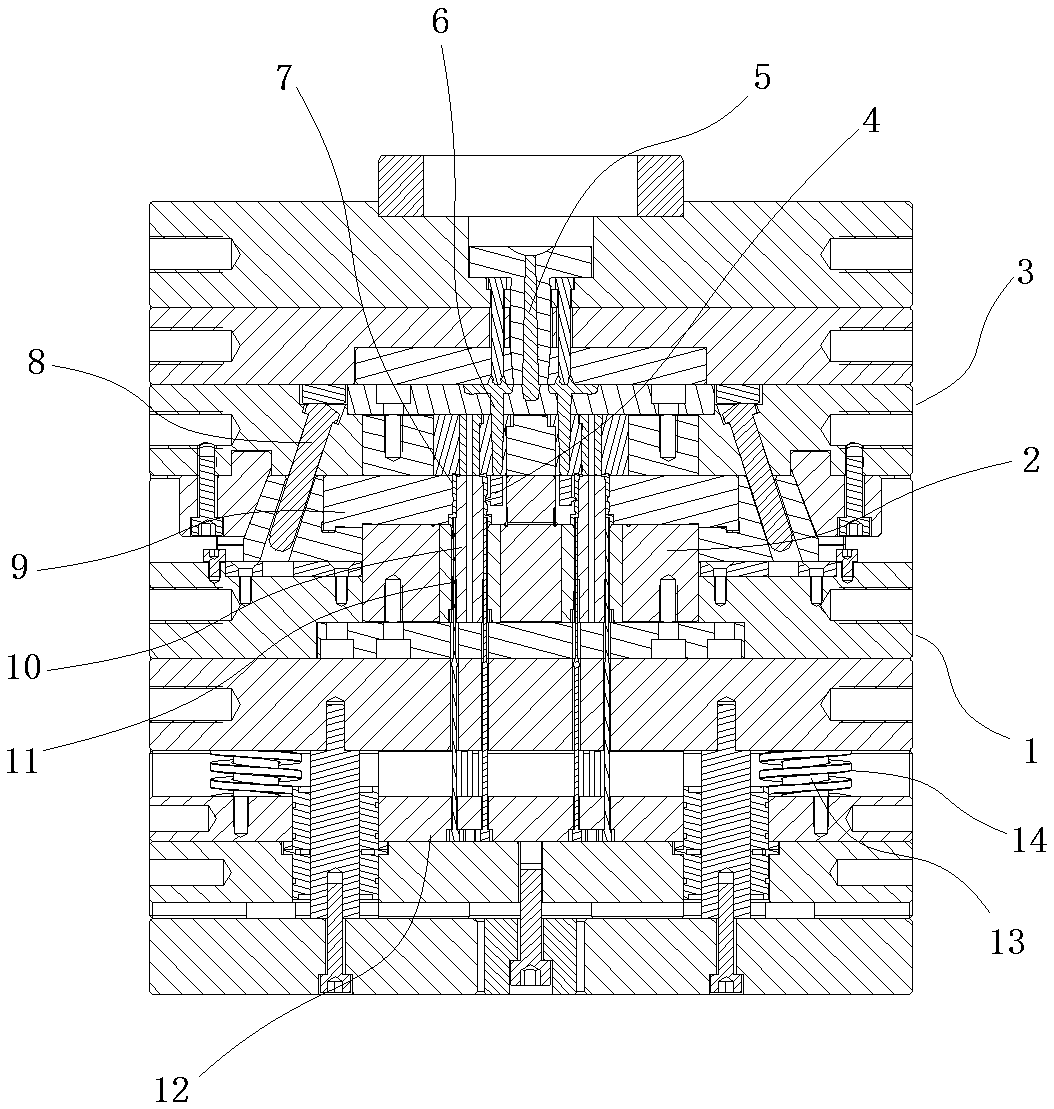

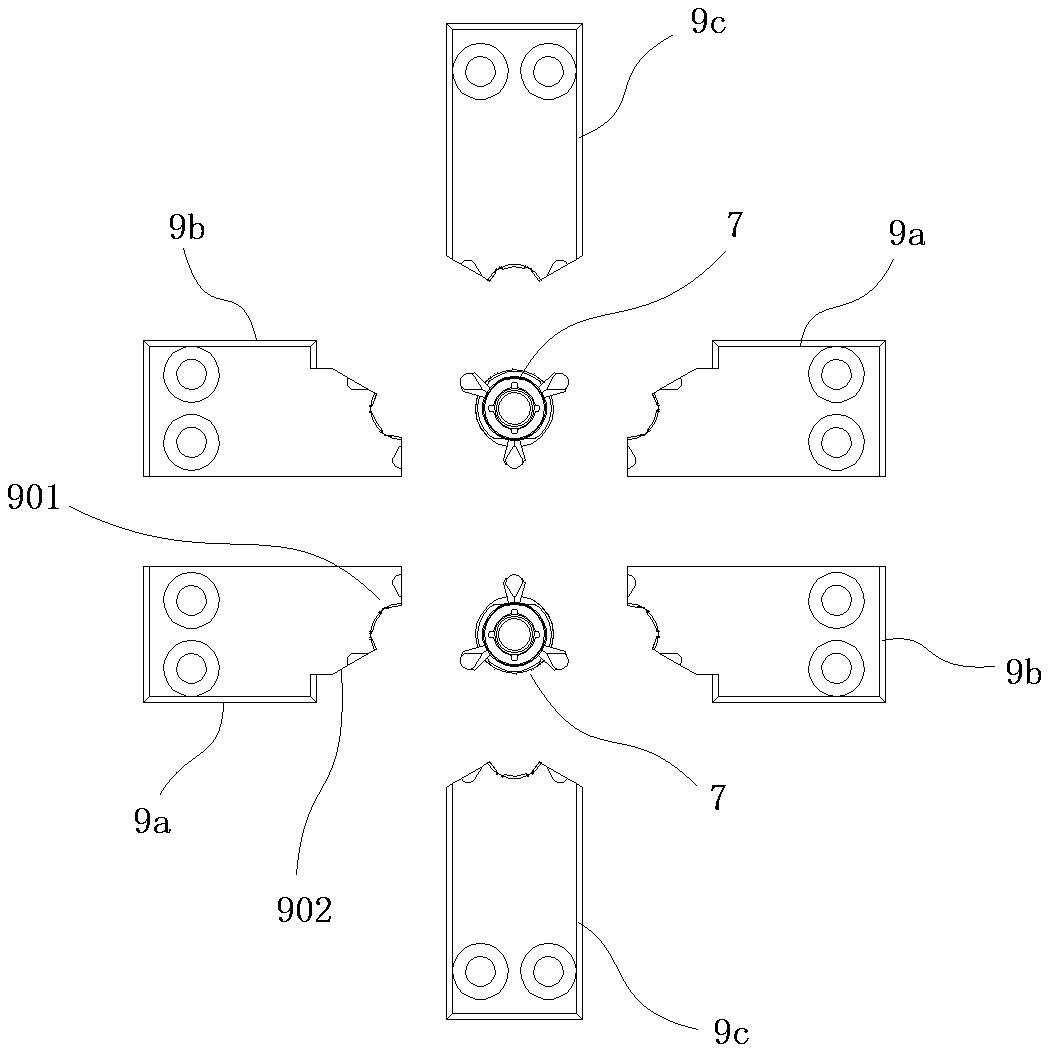

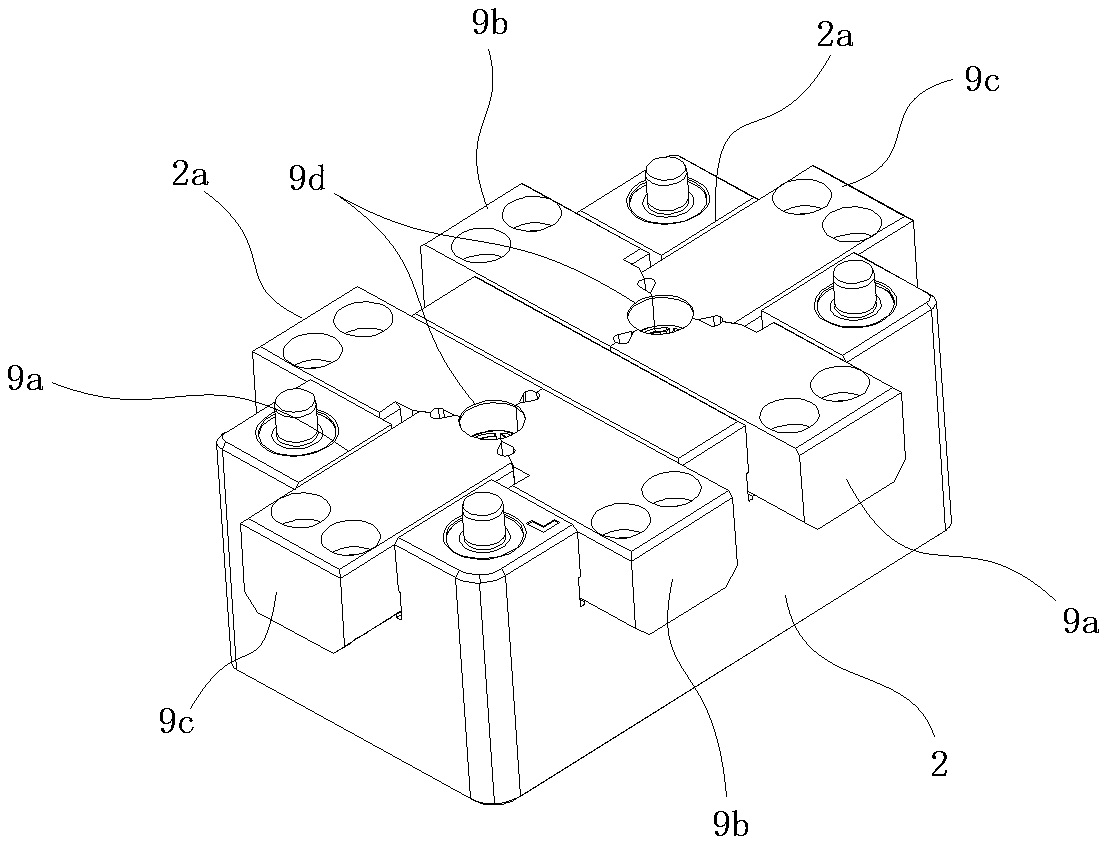

[0020] Such as figure 1 , figure 2 In the shown embodiment, a side gate vertical runner and a plastic mold for side gates include a static mold 3 and a movable mold 1 located below the static mold 3, and a side of the movable mold 1 near the parting surface is provided with Die kernel 2, mold kernel 2 is provided with slide block 9, and slide block comprises first slide block 9a, second slide block 9b and the 3rd slide block 9c, static mold 3 is provided with the first slide block 9a, the second slide block The block 9b and the third slider 9c independently correspond to the inclined guide pillar 8 that drives the first slider 9a, the second slider 9b and the third slider 9c to slide outward when the movable mold 1 is away from the static mold 3 . The movable mold 1 is provided with a thimble 11 corresponding to the cavity 9d. The movable mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com