Automatic pressing and buckling device of wallboard mold

A technology for moulds and wall panels, applied in the field of automatic pressing and releasing devices, can solve the problems of time-consuming, difficult to remove, easy to form dirt, etc., and achieve the effect of pressing and releasing fast and convenient, improving production efficiency and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

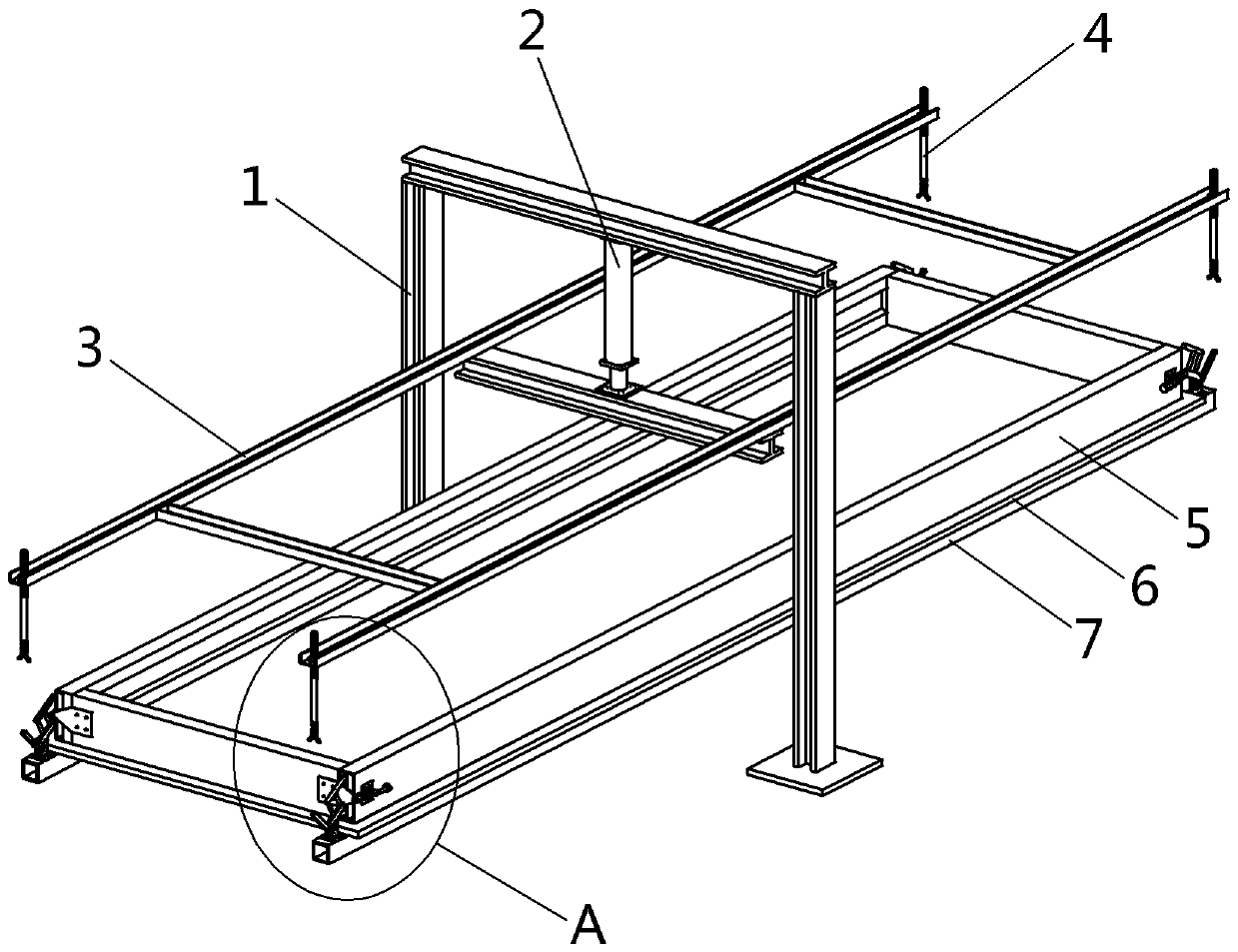

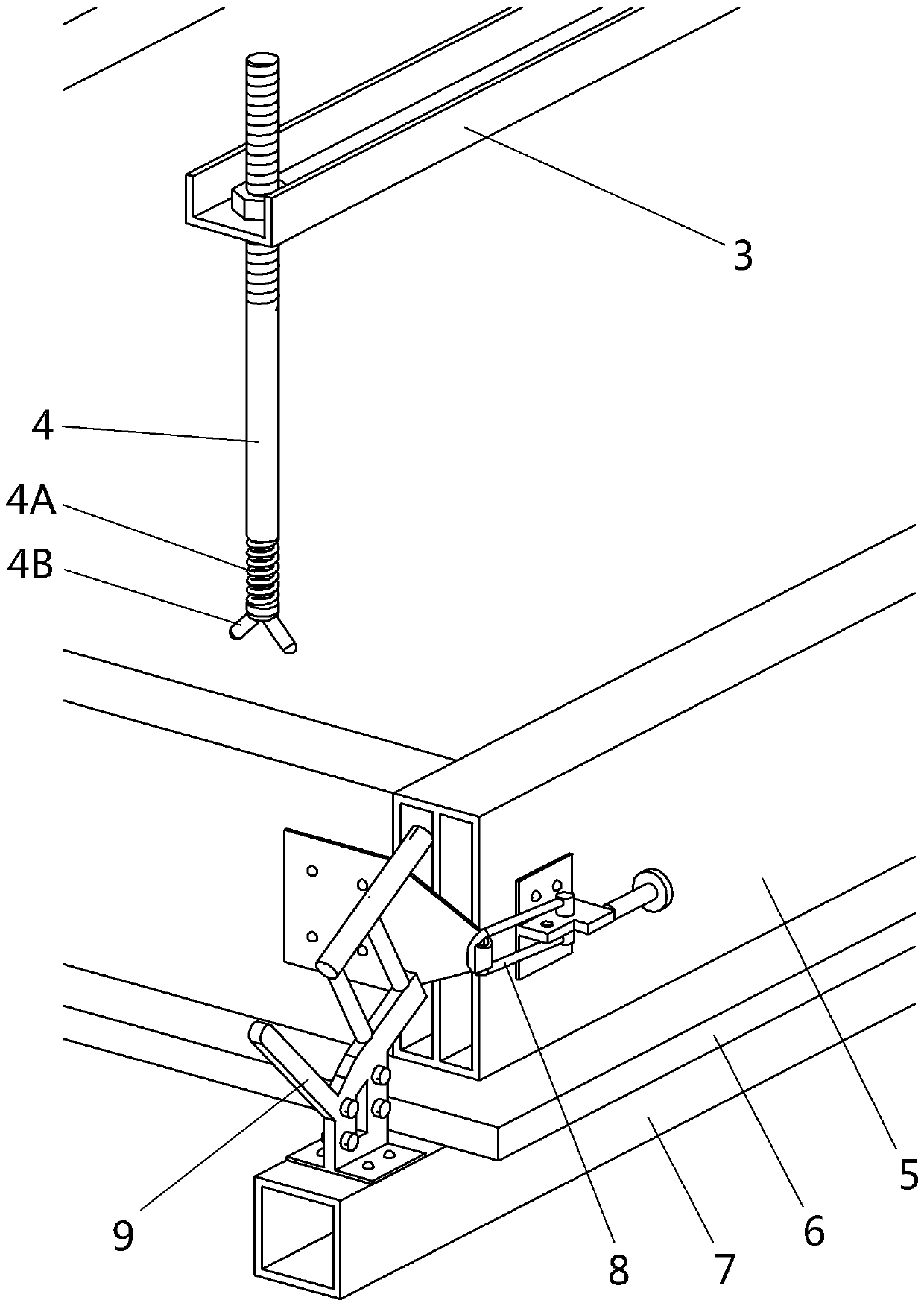

[0031] refer to figure 1 , figure 2 , The automatic pressing device of the wallboard mold of the present invention includes a gantry 1, a cylinder 2, a pressing frame 3, a pressing bar 4, a mold bracket 7, and a quick clamp 9. The gantry 1 is fixed on the ground; the cylinder 2 is installed on the gantry 1; the press frame 3 is connected to the cylinder 2, and moves up and down under the drive of the cylinder 2; On the four corners of the press frame 3, its position in the vertical direction corresponds to the position of the four quick clips 9 on the mold bracket 7. During work, the press bar 4 moves up and down with the press frame 3, and moves to When the lower end is just able to touch the quick clamp 9 on the mold bracket 7; Placed on the mold bracket 7; four quick clips 9 (compression type quick clips) are installed on the mold bracket 7, and the four quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com