Catalyst for decomposing heavy components in neopentyl glycol synthesis waste liquid and its preparation method and application

A technology of neopentyl glycol and catalyst, which is applied in the field of catalyst for decomposing heavy components in neopentyl glycol synthesis waste liquid and its preparation, can solve the problems of low conversion rate of ester decomposition, and achieve improved utilization, enhanced alkalinity, The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

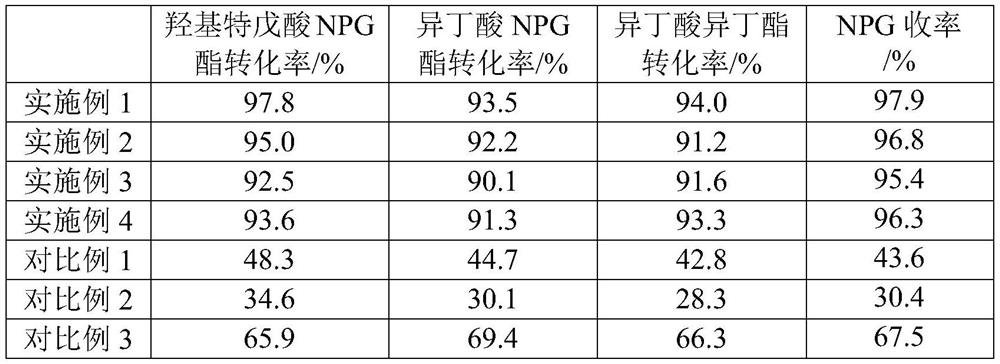

Examples

Embodiment 1

[0053] Catalyst Preparation for Decomposing Heavy Components in Neopentyl Glycol Synthesis Waste Liquid

[0054] (1) Weigh Mg(NO 3 ) 2 ·6H 2 O (molecular weight 256) 16.00g, Zr (NO 3 ) 4 ·5H 2 O (molecular weight 429) 3.49g and Al (NO 3 ) 3 9H 2 14.70 g of O (molecular weight 375) was dissolved in 100 mL of deionized water to obtain solution A. Weigh 4.5 g of sodium hydroxide and 12.0 g of sodium carbonate, and dissolve them together in 200 mL of deionized water to obtain solution B.

[0055] (2) Add solution A and solution B dropwise to 100mL deionized water, adjust the dropping rate at any time to stabilize the pH of the solution between 9 and 10, and control the reaction temperature to 50°C. Stir at a rotating speed for 60 minutes.

[0056] (3) Put the stirred mixed solution into a constant temperature tank, age at 70° C. for 16 hours, filter with suction and wash with water until the pH of the filtrate is 7. Dry the filter cake at 60°C for 20h, then put it into ...

Embodiment 2

[0063] Catalyst Preparation for Decomposing Heavy Components in Neopentyl Glycol Synthesis Waste Liquid

[0064] (1) Weigh MgSO respectively 4 (Molecular weight 120) 3.00g, Zr(NO 3 ) 4 ·5H 2 O (molecular weight 429) 6.98g and AlCl 3 ·6H 2 O (molecular weight 241) 9.45g was dissolved in 100mL deionized water together to obtain solution A. Weigh 5.0 g of sodium hydroxide and 13.3 g of sodium carbonate, and dissolve them together in 200 mL of deionized water to obtain solution B.

[0065] (2) Add solution A and solution B dropwise to 100mL deionized water, adjust the dropping rate at any time to stabilize the pH of the solution between 9 and 10, and control the reaction temperature to 40°C. Stir at a rotating speed for 50 min.

[0066] (3) Put the stirred mixed solution into a constant temperature tank, age at 60° C. for 24 hours, filter with suction and wash with water until the pH of the filtrate is 7.

[0067] Dry the filter cake at 60°C for 16h, then put it into a muf...

Embodiment 3

[0073] Catalyst Preparation for Decomposing Heavy Components in Neopentyl Glycol Synthesis Waste Liquid

[0074] (1) Weigh MgCl separately 2 ·6H 2 O (molecular weight 203) 15.23g, Zr (SO 4 ) 2 4H 2 O (molecular weight 355) 8.66g and Al (NO 3 ) 3 9H 2 O (molecular weight 375) 7.35g, dissolve in 100mL deionized water together, obtain solution A. Weigh 3.5g of sodium hydroxide and 9.3g of sodium carbonate, and dissolve them together in 200mL of deionized water to obtain solution B.

[0075] (2) Add solution A and solution B dropwise to 100mL deionized water, adjust the dropping rate at any time to stabilize the pH of the solution between 9 and 10, and control the reaction temperature to 60°C. Stir at high speed for 30 min.

[0076] (3) Put the stirred mixed solution into a constant temperature tank, age at 80° C. for 16 hours, filter with suction and wash with water until the pH of the filtrate is 7.

[0077] Dry the filter cake at 70°C for 16h, then put it into a muffl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com