A method for testing the vertical direction resistance of fuel cell catalytic layer

A vertical direction, fuel cell technology, applied in the direction of material electrochemical variables, measuring electricity, measuring electrical variables, etc., to achieve the effect of real data and flexible and convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

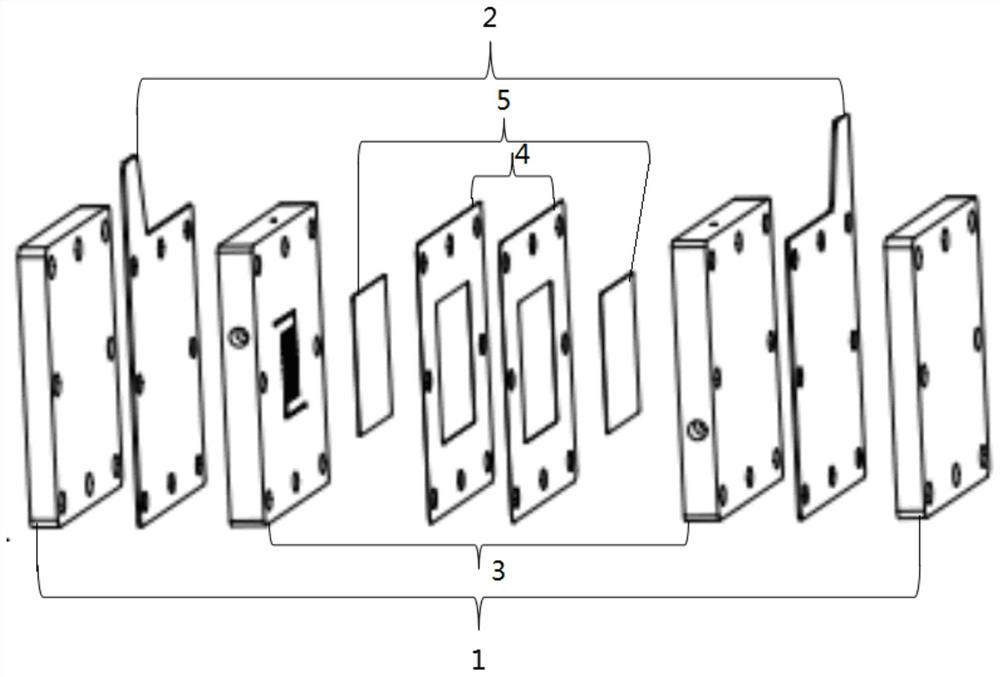

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

[0021] The method for testing the vertical resistance of the fuel cell catalyst layer comprises the following steps:

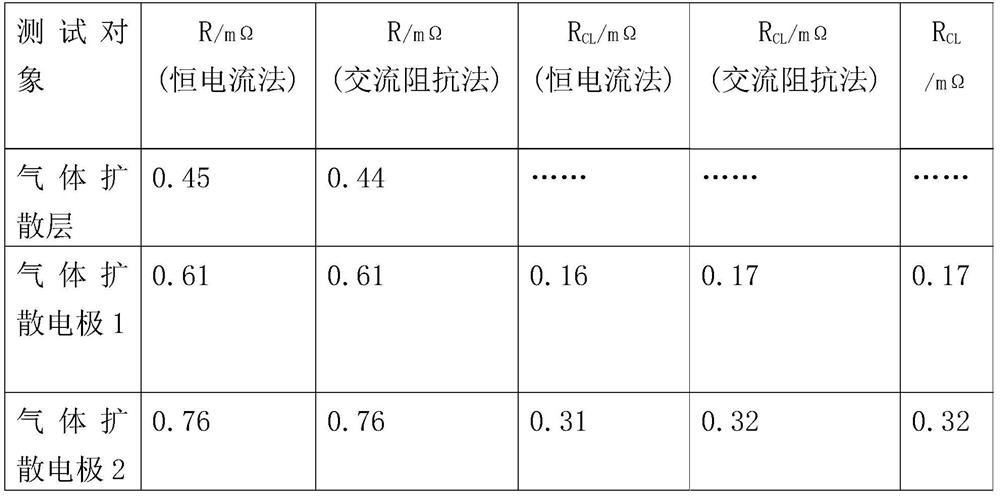

[0022] 1) Select a commercial gas diffusion layer with a thickness of 150-300 μm, and cut it into a thickness of 25 cm 2 The shape of the small single cell test fixture is matched. Under the condition of setting the assembly force at 4N·m for reinforcement, the cut gas diffusion layer is assembled in the small single cell test fixture, and the initial performance of the conventional membrane electrode is set in the test environment. The test conditions are 70°C, normal pressure, the flow rate of hydrogen gas into the anode and air into the cathode is 200mL / min, and the gas diffusion layer is vertically tested by the constant current method and the AC impedance method of the electrochemical workstation. For the resistance test of the direction, each tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com