A Thin-Wall Model Double-Beam Hinged Structure and Dynamic Test Support Method

A model and thin-walled technology, which is applied in the field of aerospace engineering, can solve the problems that the connection between the model and the flange is easily deformed, the hinge condition of the aircraft cannot be simulated, and the dynamic characteristics of the model cannot be simulated, so as to avoid deformation and facilitate Mounting and dismounting, the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

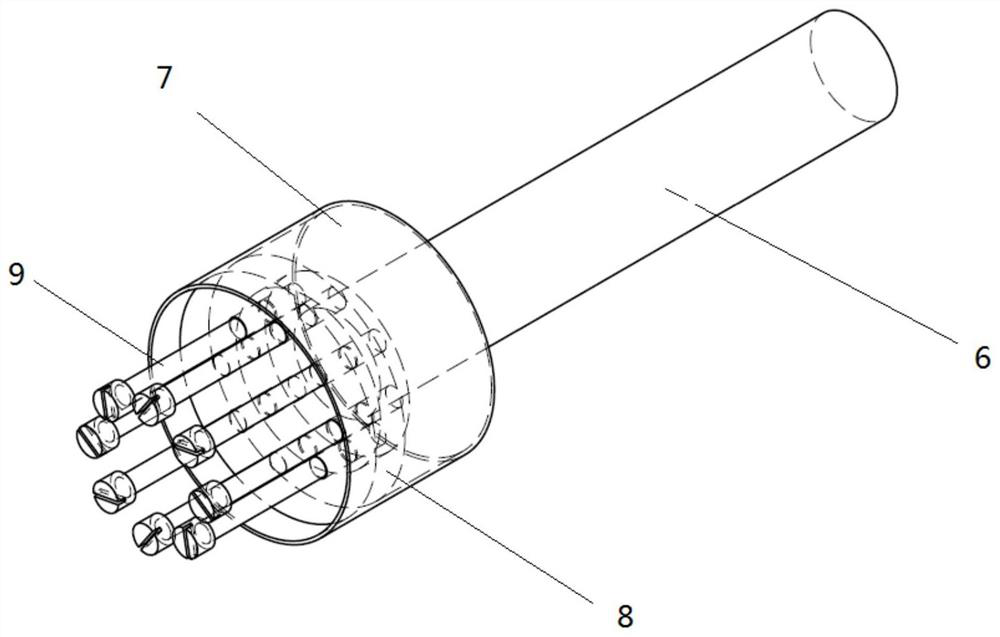

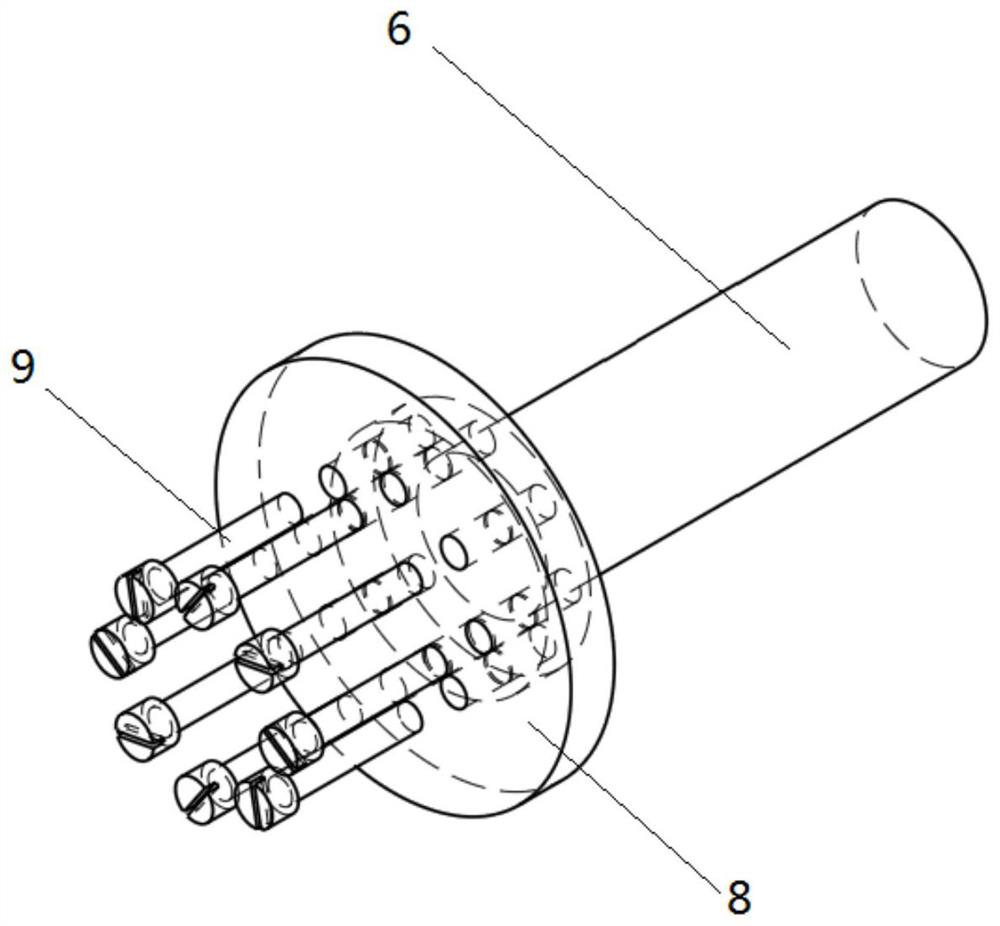

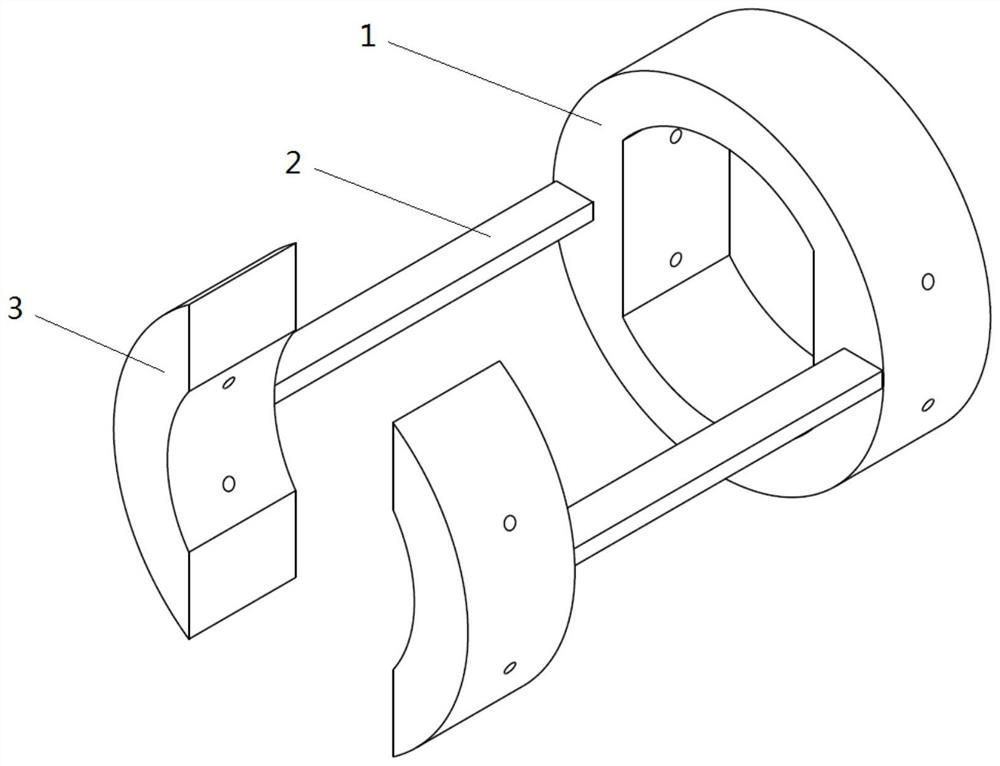

[0040] Such as image 3 , 4 As shown, the present invention includes: a pole fixing sleeve 1, an elastic beam 2, a model fixing flap 3, a pole fixing compression screw 4, a model fixing screw 5, a pole 6, a test model 7, and a model support sleeve 10.

[0041] Wherein the pole fixing sleeve 1, the elastic beam 2, and the model fixing flap 3 are integrally processed, and the model supporting sleeve 10 and the test model 7 are fixedly connected by rivets. The two elastic beams 2 are placed in parallel on the same plane, and the pole fixing sleeve 1 and the model fixing flap 3 are respectively connected to the two ends of the elastic beams. During the test, use the pole fixing compression screw 4 to compress and fix the pole fixing sleeve 1 on the pole 6, use the pole fixing compression screw 4 to fix the pole 6 and the pole fixing sleeve 1, and use the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com