An axial centroid measuring device and method based on the principle of moment balance

A torque balance and measuring device technology, applied in the direction of measuring device, static/dynamic balance test, machine/structural component test, etc., can solve problems such as error, controlled sensor accuracy and installation, and difficulty in achieving high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

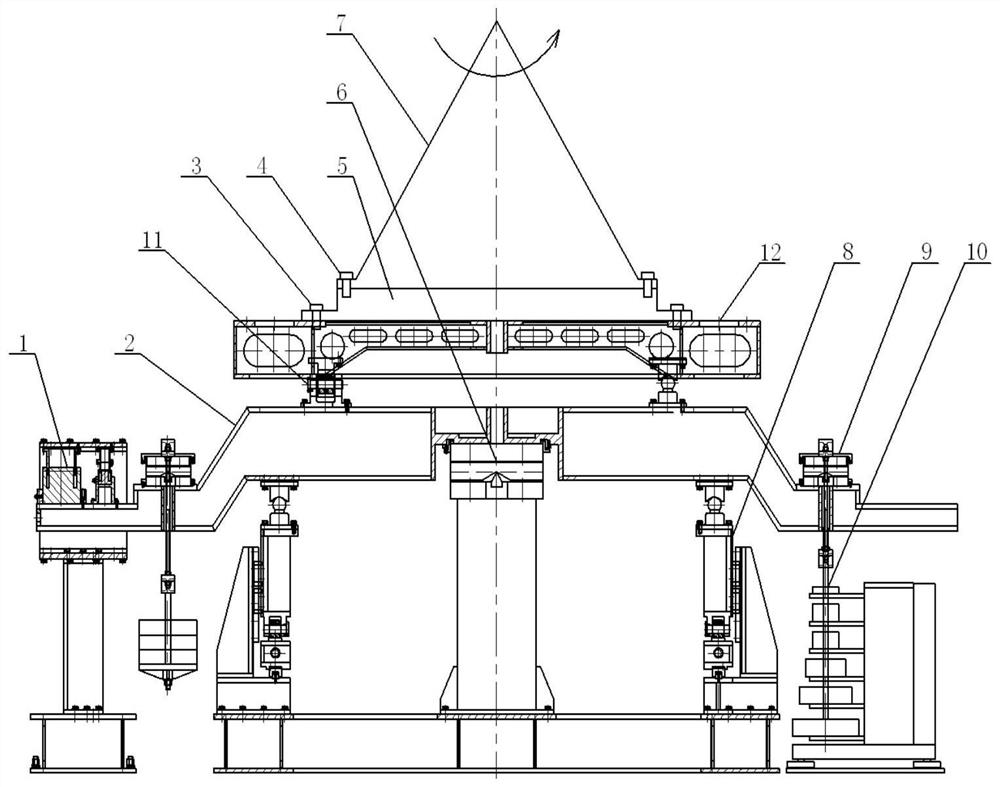

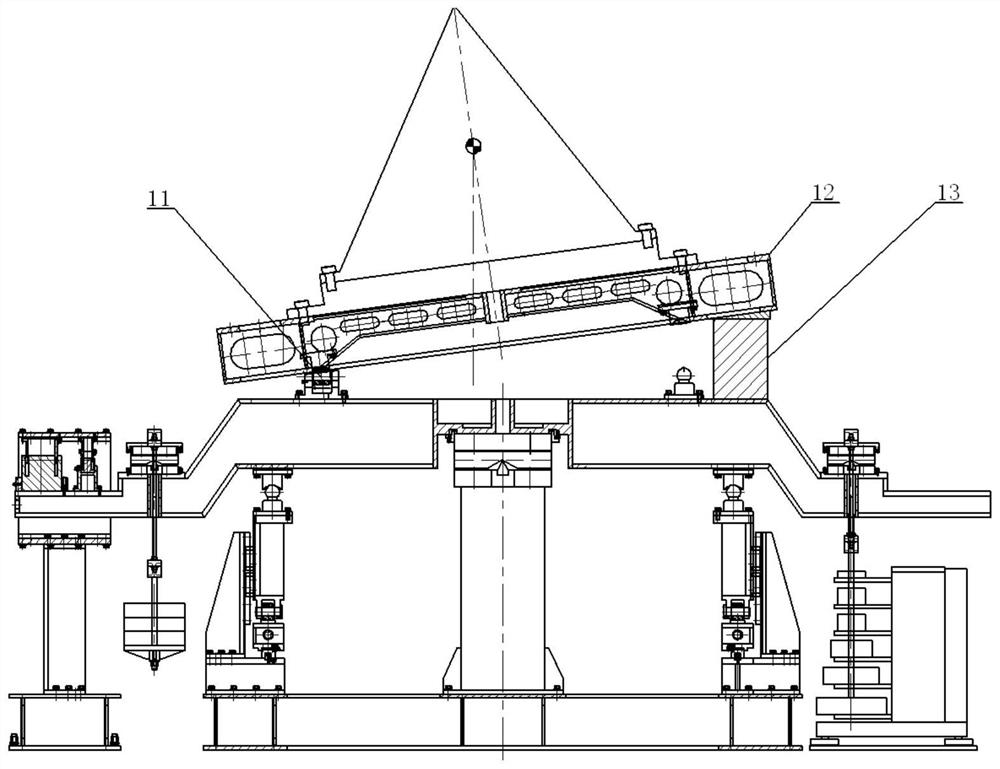

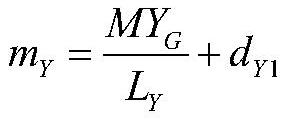

[0050] An axial center-of-mass measurement device based on the principle of moment balance, including a first-stage platform 2, which directly acts on the top of the main knife 6, and the main knife 6 is used to support the first-stage platform 2 and the components above it and maintain balance; the electromagnetic torque Device 1 is used to balance the measuring device after the weights are roughly matched during measurement. The tooling positioning pin 3 and the product positioning pin 4 are used for positioning the product tooling 5 and the product under test 7 respectively; the secondary platform 12 is arranged on the primary platform 2 above, and can be tilted 7°~8° on the first-level platform 2 around the platform shaft 11, the cushion block 13 is used to support the second-level platform 12 to form a fixed angle of inclination with the first-level platform 2, and the jacking mechanism 8 will The first-level platform 2 and the parts above it are jacked up, thereby breakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com