Check nut, check gasket and check bolt

A technology of backstop and nut, which is applied in the fields of backstop washer, backstop bolt and backnut, can solve the problems of complex production process and high machining precision of backstop nut, and achieve the effects of convenient use, increased bite force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

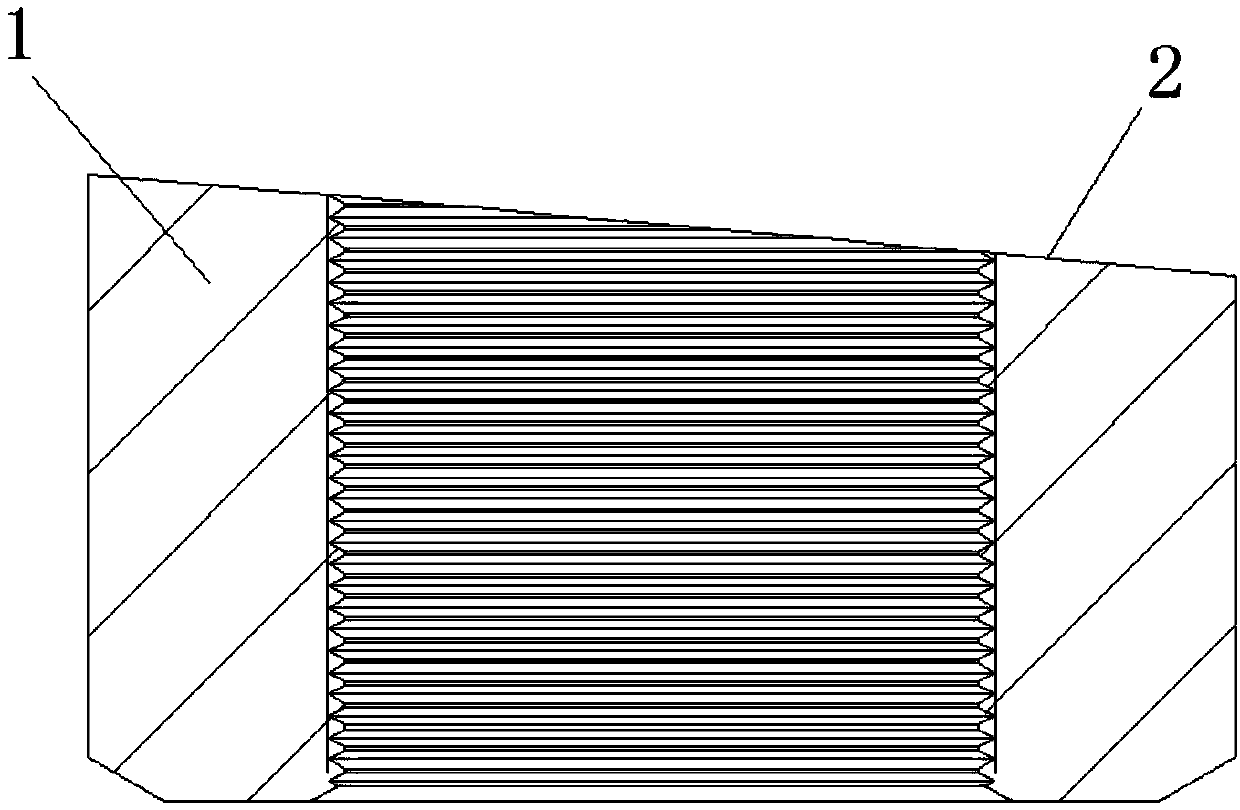

[0034] A back nut such as figure 1 and figure 2 As shown, it includes a nut body 1, the end surface of one end of the nut body 1 is a slope 2, and the angle between the slope 2 and the plane where the end surface of the other end of the nut body 1 is located is A, and A is greater than 0° and less than 90°.

[0035] When using the anti-retraction nut with the above structure, the worker can direct the slope 2 of the nut body 1 toward the workpiece 4 and connect and fix it with the screw or bolt, so that the lowest point of the slope 2 contacts the workpiece 4. At this time, The staff can continue to tighten the nut body 1, so that the inclined surface 2 of the nut body 1 fits the workpiece 4, and the internal thread on the nut body 1 squeezes the external thread on the screw or the bolt, so that the external thread on the screw or the bolt produces elasticity deformation, so as to increase the bite force on the nut body 1 and the screw rod or bolt, and then achieve the effec...

Embodiment 2

[0039] Such as figure 1 and image 3 As shown, as another specific embodiment of a stop nut of the present invention, the stop nut also includes a fastening nut 3 used in conjunction with the nut body 1, through the cooperation of the fastening nut 3 and the nut body 1, The anti-retraction nut also has a good anti-retraction effect, and can also protect the workpiece 4 well, so that the workpiece 4 will not be squeezed by the nut body 1 and cause the workpiece 4 to be damaged.

[0040] During specific use, the staff can install the above-mentioned nut body 1 on the screw rod or bolt on the workpiece 4, make the inclined surface 2 of the nut body 1 away from the side of the workpiece 4, and then install the fastening nut 3 on the screw rod correspondingly. Or on the bolt, make the fastening nut 3 contact with the highest point of the slope 2 of the nut body 1. At this time, the staff can continue to twist the fastening nut 3 so that the lower end surface of the fastening nut 3...

Embodiment 3

[0046] Such as Figure 4 As shown, the present invention provides a back-stop washer, which includes a washer body 5 and a fastening nut 3. The end face at one end of the washer body 5 is an inclined plane 2, and the plane between the inclined plane 2 and the end face at the other end of the washer body 5 is located. The angle is B, and B is greater than 0° and less than 90°; the fastening nut 3 is located on one side of the bevel 2 of the washer body 5 .

[0047] With the anti-retraction washer of the above structure, the end surface of the fastening nut 3 is attached to the inclined surface 2 by turning the fastening nut 3. At this time, the internal thread of the fastening nut 3 squeezes the outer surface of the screw or bolt The thread makes the internal thread of the fastening nut 3 and the external thread on the screw rod or the bolt produce elastic deformation, thereby increasing the occlusal force between the internal thread in the fastening nut 3 and the external thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com