Automatic control system and method for wellhead pressure return

An automatic control system and controller technology, which is applied in earth-moving drilling, flushing wellbore, wellbore/well components, etc., can solve the problems of multiple equipment sets, complex pressure control system, and high investment cost, so as to reduce the risk of well control. , the effect of optimizing the supporting process and improving the safety operation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

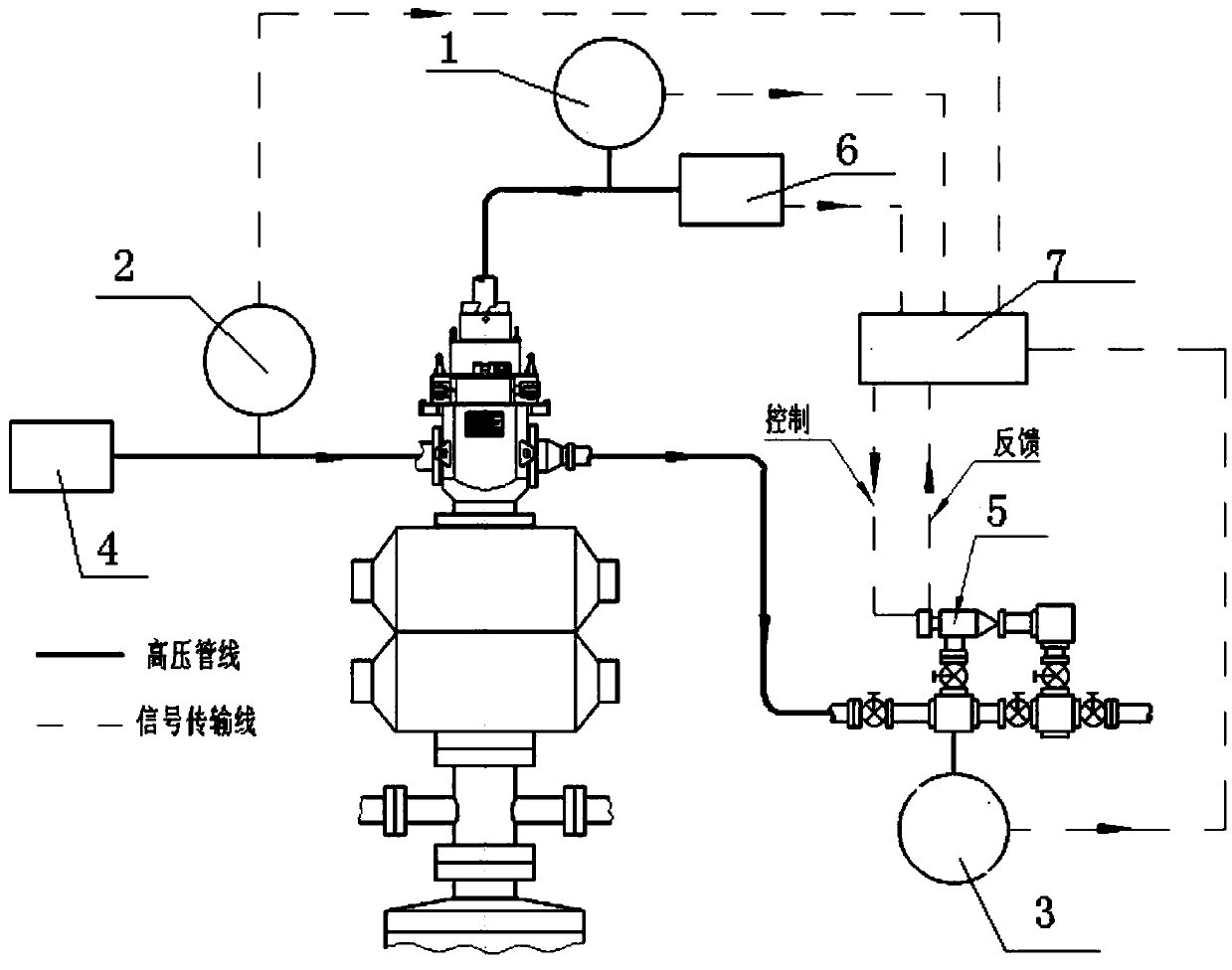

[0033] Such as figure 1 As shown, a wellhead back pressure automatic control system includes a first pressure sensor 1, a second pressure sensor 2, a third pressure sensor 3, a compensating pump 4, a throttle valve 5, a well depth sensor 6 and an analysis controller 7. A pressure sensor 1 is connected to the wellhead riser, a well depth sensor 6 is connected to the wellhead through a high-pressure pipeline, one end of the compensation pump 4 is connected to the second pressure sensor 2, the other end of the compensation pump 4 is connected to the wellhead inlet through a high-pressure pipeline, and the wellhead outlet is connected to the second pressure sensor through a high-pressure pipeline. One end of the three pressure sensors 3, the other end of the third pressure sensor 3 is connected to the throttle valve 5; the analysis controller 7 is respectively connected to the first pressure sensor 1, the second pressure sensor 2, the third pressure sensor 3, and the throttle valve...

Embodiment 2

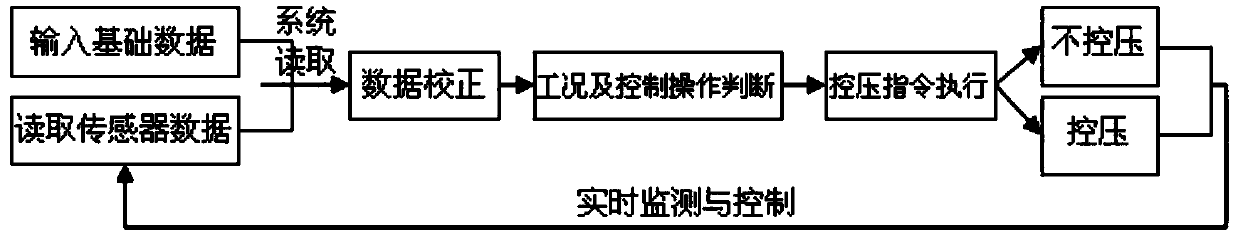

[0040] Such as Figure 2-3 Shown, on the basis of embodiment 1, a kind of wellhead back pressure automatic control method comprises the steps:

[0041] 1) acquire data, analyze controller 7 input basic parameter data and real-time parameter data and store;

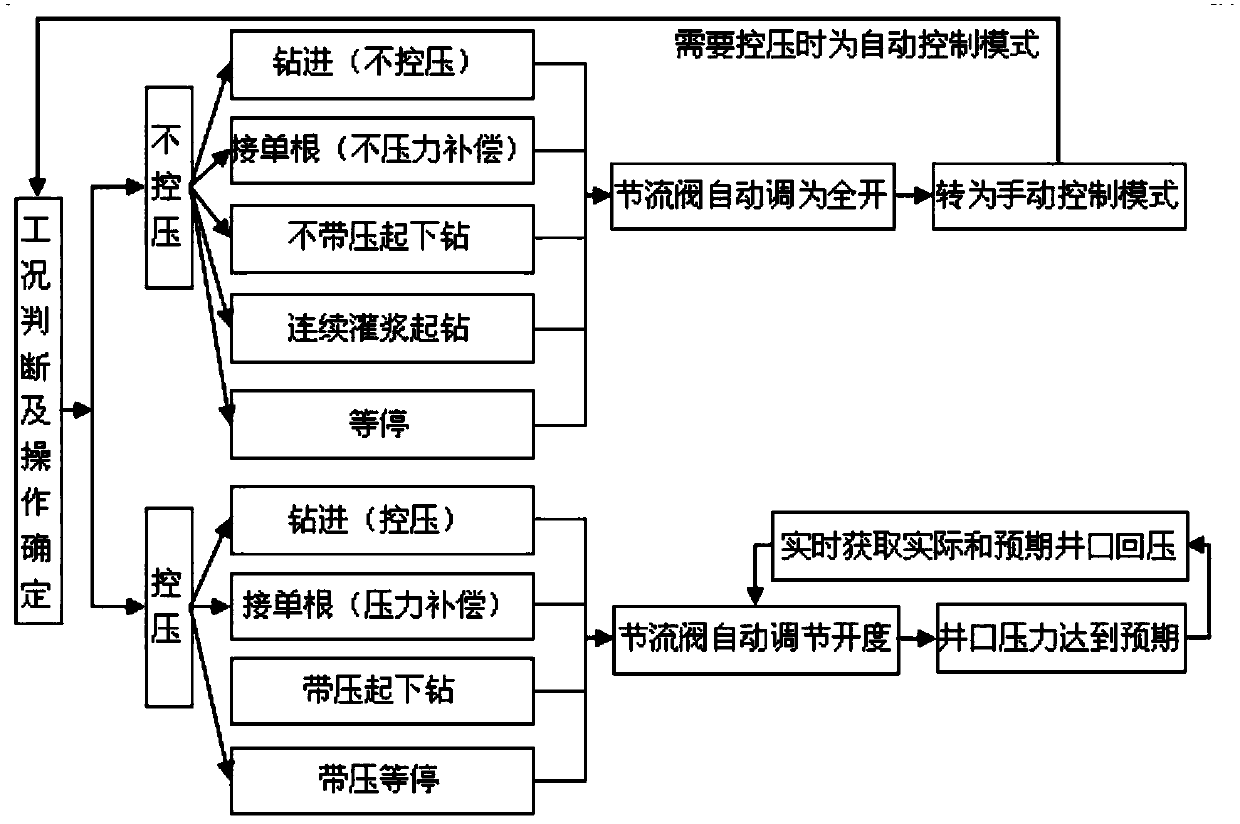

[0042] 2) analyze the data, the analysis controller 7 calculates the data obtained in step 1) to obtain the pressure data for realizing the judgment operation, and judges the working conditions and control operations;

[0043] 3) Executing operations and analyzing The controller 7 formulates execution instructions according to working conditions and control operation judgments to realize automatic control of wellhead back pressure.

[0044] Said step 2) judge the pressure data of the operation according to the pressure value P obtained by shutting down the well cw , Shut in the well and find the kill depth H cw , real-time well depth H rt , drilling fluid performance and displacement, wellbore structure, drilling tool ...

Embodiment 3

[0061] On the basis of Embodiment 2, the present invention takes the system automatic judgment and pressure control process of the working condition of well head pressure-controlled drilling connected to a single root (pressure compensation) as an embodiment.

[0062] (1) obtain data, analyze controller 7 input basic parameter data and real-time parameter data and store;

[0063] Input basic data: stop and start pump judgment value P sp , preset wellhead back pressure value P wd , Preset wellhead back pressure value P under non-circulation condition ma , Pressure control precision P ca , Shut in the well and calculate the pressure value P cw , Shut in the well and find the kill depth H cw , Drilling fluid performance and displacement, well structure, drilling tool assembly;

[0064] Read sensor data: standpipe pressure P d , Compensation source pressure P sc , wellhead back pressure P w , real-time well depth H rt ;

[0065] (2) Analyzing the data, the analysis contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com