Polymeric dispersant and environment-friendly surface sizing agent prepared by utilizing the same

A technology of polymerizing dispersant and surface sizing agent, which is applied in the direction of water repellent addition, etc., can solve the problems of high VOC and residue, and achieve the effects of low Cobb value, good water resistance, and low residual monomer in emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

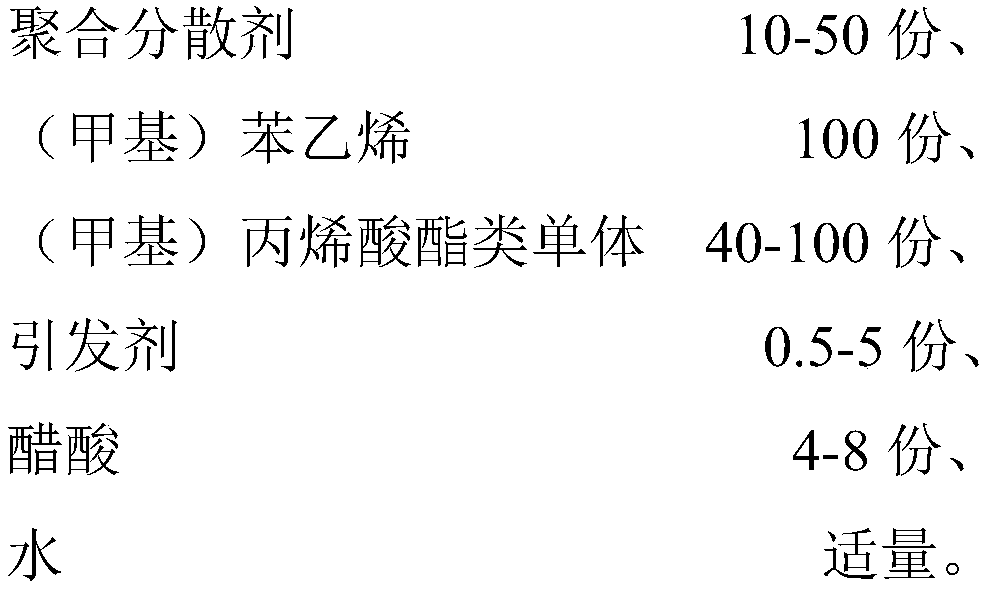

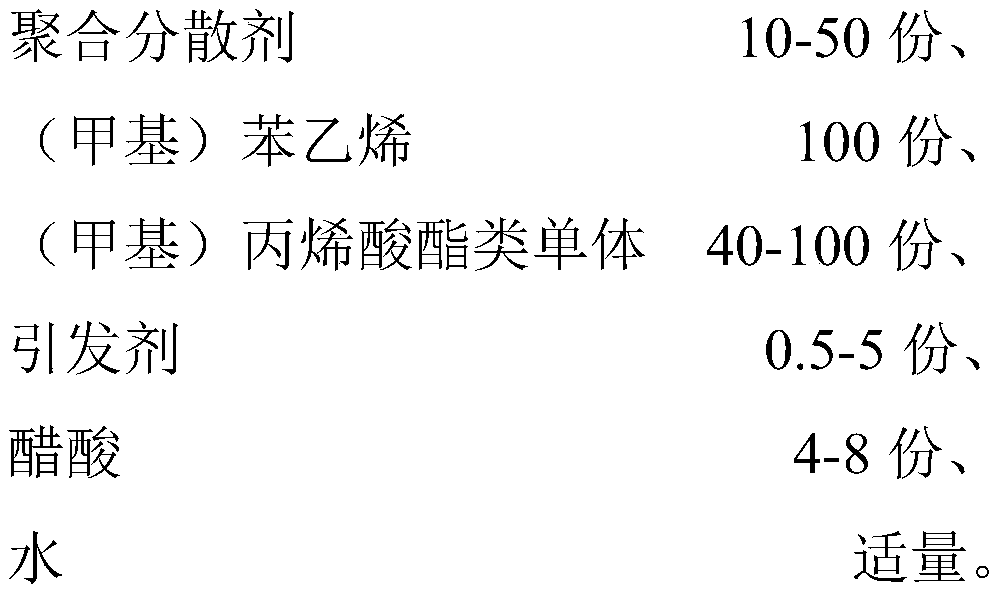

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of polymeric dispersant:

[0032] In a 1000ml four-necked flask equipped with a condenser, a dropping device, a stirrer and a thermometer, add 100 grams of maleic anhydride and 600 grams of polyvinyl alcohol, heat and melt, and react at 80° C. for 3 hours. The temperature was lowered to 40°C and 120 g of chlorosulfonic acid was added, and the reaction was continued for 1 hr.

[0033] 2. Preparation of environment-friendly surface sizing agent:

[0034] In a 1000ml four-neck flask equipped with a condenser, a dropping device, a stirrer and a thermometer, add 10 grams of polymeric dispersant, 500 grams of deionized water, and 4 grams of acetic acid, then heat up to 80°C, and add 1 grams of ammonium persulfate. After reacting for 10 minutes, 180 g of mixed monomers (100 g of styrene, 80 g of ethyl acrylate) were slowly added dropwise, and the addition was completed within 1.5 hr. 0.5 g of ammonium persulfate was added to continue the reaction for 1 hr. Af...

Embodiment 2

[0036] 1. Preparation of polymeric dispersant:

[0037] In a 1000ml four-necked flask equipped with a condenser, a dropping device, a stirrer, and a thermometer, add 100 grams of maleic anhydride and 650 grams of polyvinyl alcohol, heat to dissolve, and react at 90°C for 3 hours. Cool down to 50°C and add 125g of chlorosulfonic acid to continue the reaction for 1.5hr.

[0038] 2. Preparation of environment-friendly surface sizing agent:

[0039] In a 1000ml four-neck flask equipped with a condenser, dropping device, stirrer, and thermometer, add 20 grams of polymeric dispersant, 600 grams of deionized water, and 4 g of acetic acid, then heat up to 90° C., and add 1 g of potassium persulfate. After reacting for 10 minutes, 200 grams of mixed monomers (100 g of styrene, 100 g of n-butyl acrylate) were slowly added dropwise, and the addition was completed in 2.0 hours. 0.5 g of potassium persulfate was added to continue the reaction for 1 hr. After cooling, filter through a 32...

Embodiment 3

[0041] 1. Preparation of polymeric dispersant:

[0042] In a 1000ml four-necked flask equipped with a condenser, a dropping device, a stirrer and a thermometer, add 100 grams of maleic anhydride and 700 grams of polyvinyl alcohol, heat to dissolve, and react at 95° C. for 3 hours. Cool down to 50°C and add 130g of chlorosulfonic acid to continue the reaction for 2.5hr.

[0043] 2. Preparation of environment-friendly surface sizing agent:

[0044] In a 1000ml four-necked flask equipped with a condenser, dropping device, stirrer, and thermometer, add 35 grams of polymeric dispersant, 530 grams of deionized water, 4 g of acetic acid, heat up to 90 ° C, and add 3 g of dibenzoyl peroxide . After 15 minutes of reaction, 160 g of mixed monomers (100 g of styrene, 60 g of isooctyl acrylate) were slowly added dropwise, and the addition was completed in 2.0 hr. 1.0 g of potassium persulfate was added to continue the reaction for 1 hr. After cooling, filter through a 325-mesh filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com