A lift-and-joint clothes-drying pole structure

A clothes rail and docking technology, which is applied in the field of lifting and docking clothes rail structure, can solve the problems of unsatisfactory drying treatment effect and inability to achieve complete drying, and achieve the elimination of rotation displacement error accumulation and precise positioning The effect of accumulating rotation displacement error and preventing back and forth shaking and disengagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

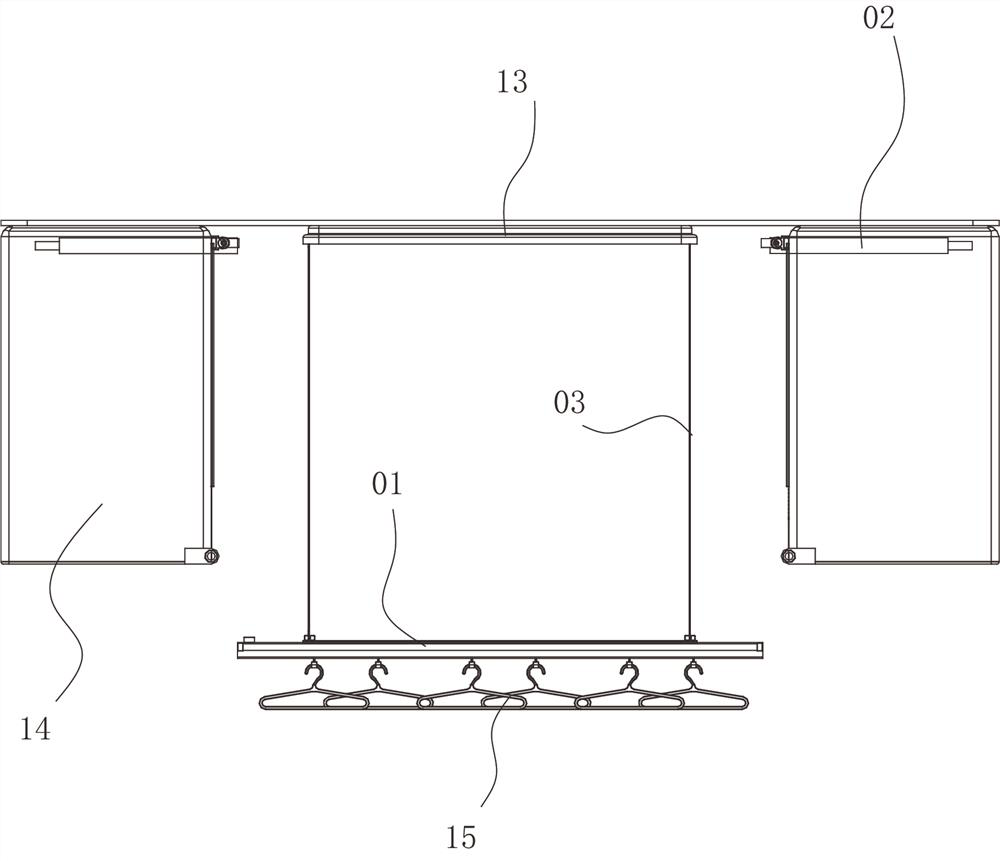

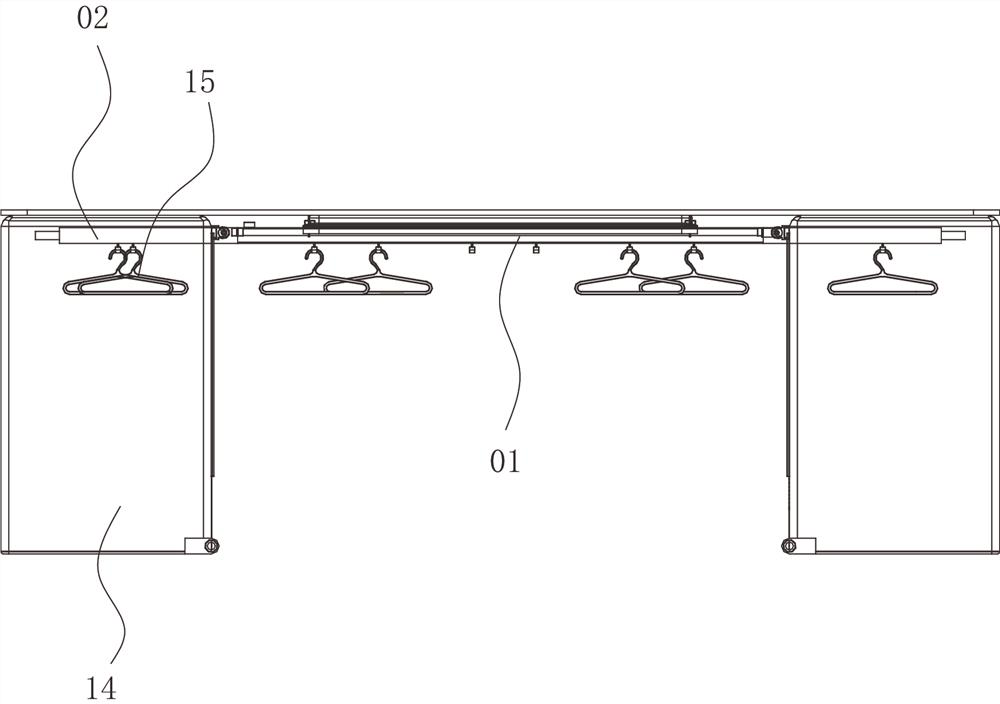

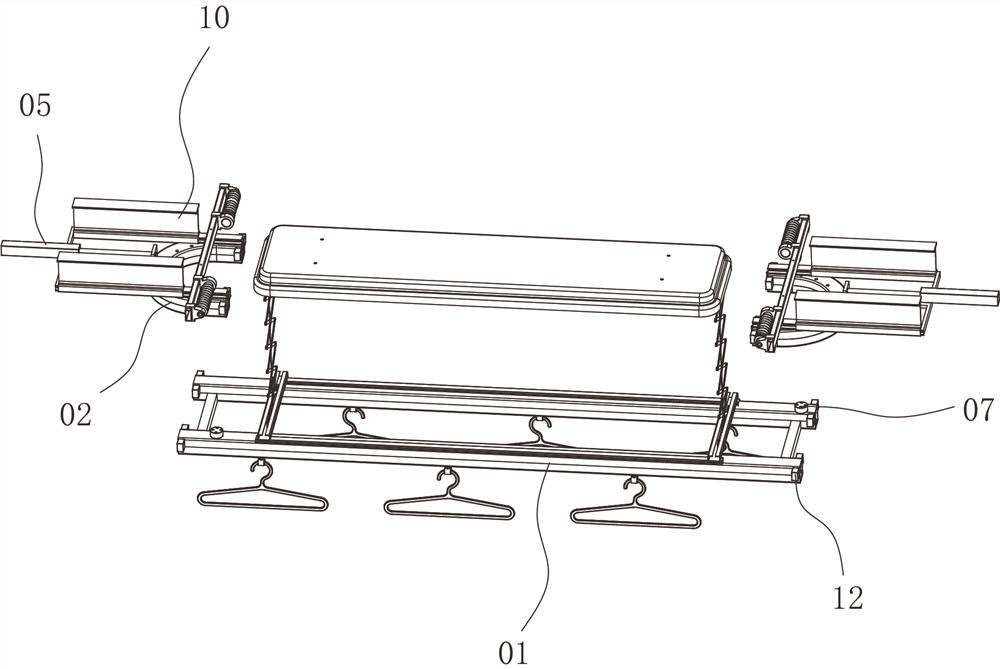

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1-10 As shown, marked as follows: Rectangular drying frame 01, profile main pipe 1a, bottom cover plate 1b, U-shaped drying frame 02, U-shaped upper cover 2a, U-shaped lower cover 2b, lifting rope 03, electric push rod 05, toothed belt 06. Protruding strip 6a, groove 6b, tooth groove 6c, transmission motor 07, clothes hook assembly 08, cross body 8a, tooth column 8b, hook ring 8c, rolling wheel 8d, guide column wheel 09, sliding frame 10, push rod Seat 11, cylinder type contact displacement sensor 12, telescoping rod 12a, trapezoidal groove 12b, main machine 13 for drying clothes, oven 14, clothes hook 15.

[0023] A lift-and-joint clothes-drying pole structure includes a rectangular drying frame 01 that moves up and down and a U-shaped drying frame 02 that moves horizontally. Lifting rope 03 and lifting motor (not shown in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com