Passivating agent for zinc plating and zinc plating passivation method

A passivating agent and oxidizing agent technology, applied in the direction of metal material coating process, etc., can solve the problems of purple, blue corners easy to yellow, immature technology, etc., and achieve the effect of good color effect

Inactive Publication Date: 2019-03-29

广州传福化学技术有限公司

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the current trivalent chromium blue passivation technology is immature. The blue color obtained by galvanized trivale

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

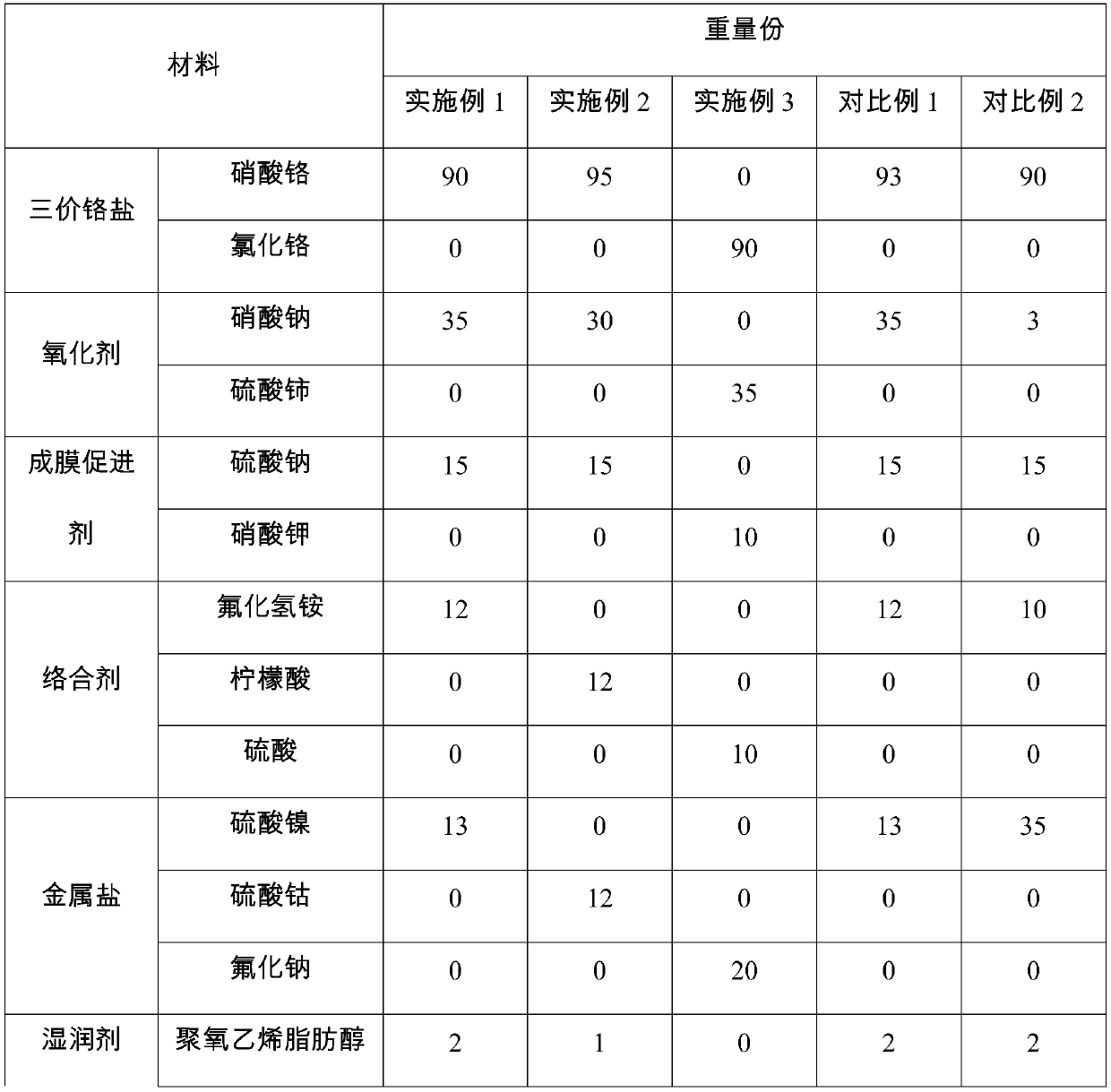

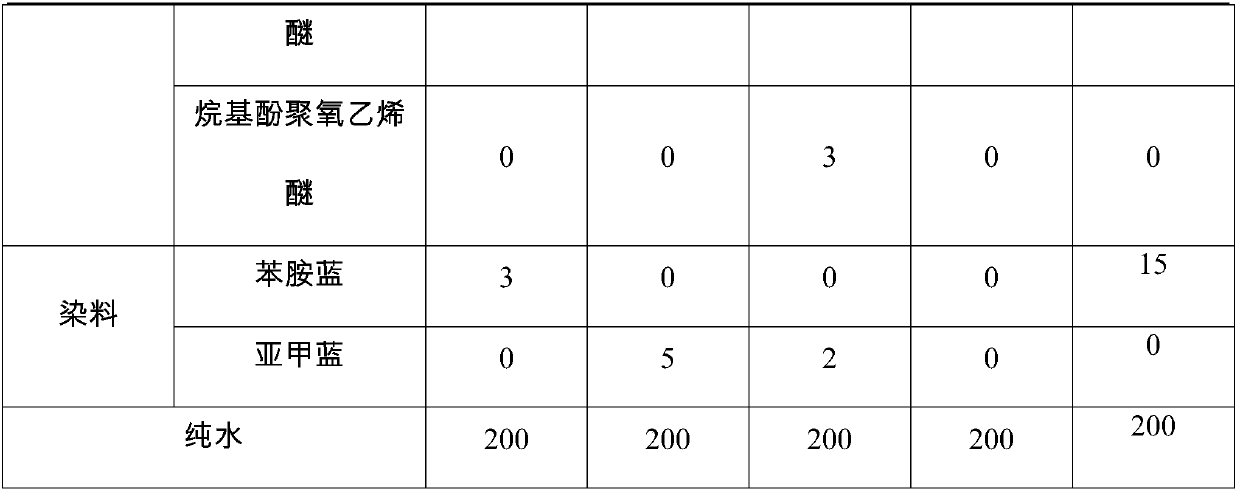

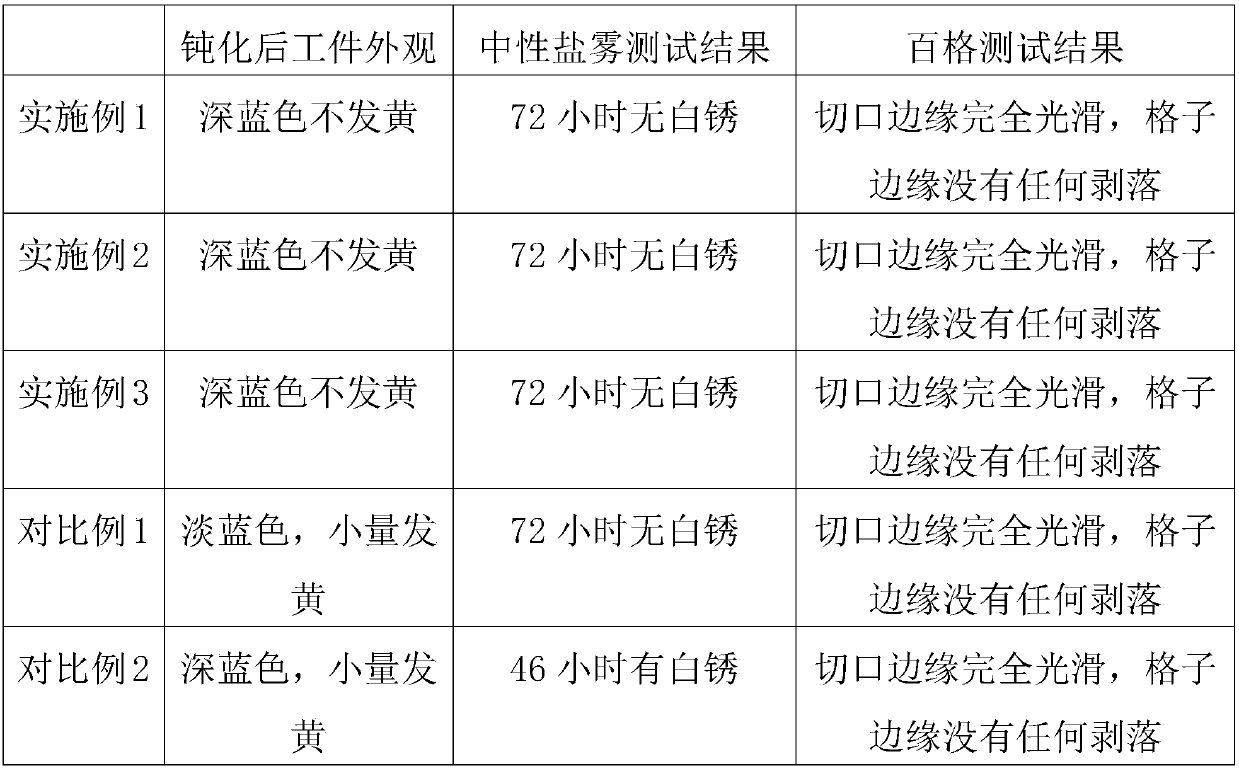

The invention provides a passivating agent for zinc plating and a zinc-plating passivation method. The passivating agent for zinc plating provided by the invention comprises 50-150 parts of chromic salts, 10-50 parts of oxidants, 5-30 parts of film-forming accelerators, 5-30 parts of complexing agents, 5-30 parts of metal salts and 0.1-10 parts of dyestuffs. The dyestuffs comprise one or more of the aniline blue, the methyl blue and the methylene blue. According to the passivating agent for zinc plating and the zinc-plating passivation method, workpieces passivated by the passivating agent have a good appearance.

Description

technical field [0001] The invention belongs to the technical field of electroplating chemistry, and in particular relates to a passivating agent for galvanizing and a galvanizing passivation method. Background technique [0002] Electrogalvanizing is an effective way to improve the corrosion resistance of steel parts, and is widely used in many fields such as construction, transportation, machinery, electronics, and aviation. However, in a humid environment, the galvanized layer is prone to corrosion, causing the surface of the coating to form a dark gray or white loose corrosion product, that is, white rust; after a long time, red rust will appear, thus losing the anti-corrosion effect. In order to improve the corrosion resistance of the coating, it is necessary to electro-galvanize the steel parts and immerse the parts in a passivation solution for passivation treatment to form a dense passivation film on the surface of the galvanized layer, thereby further improving the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C22/53C23C22/46C23C22/34

CPCC23C22/34C23C22/46C23C22/53

Inventor 黎效传刘信

Owner 广州传福化学技术有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com