A kind of anti-yellowing type β-hydroxyalkylamide curing agent and its preparation method and application

A technology of hydroxyalkyl amide and curing agent, which is used in the field of preparing powder coatings and anti-yellowing β-hydroxyalkyl amide curing agent, can solve the problems of poor anti-yellowing performance, etc., and achieve improved catalytic efficiency and anti-yellowing performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

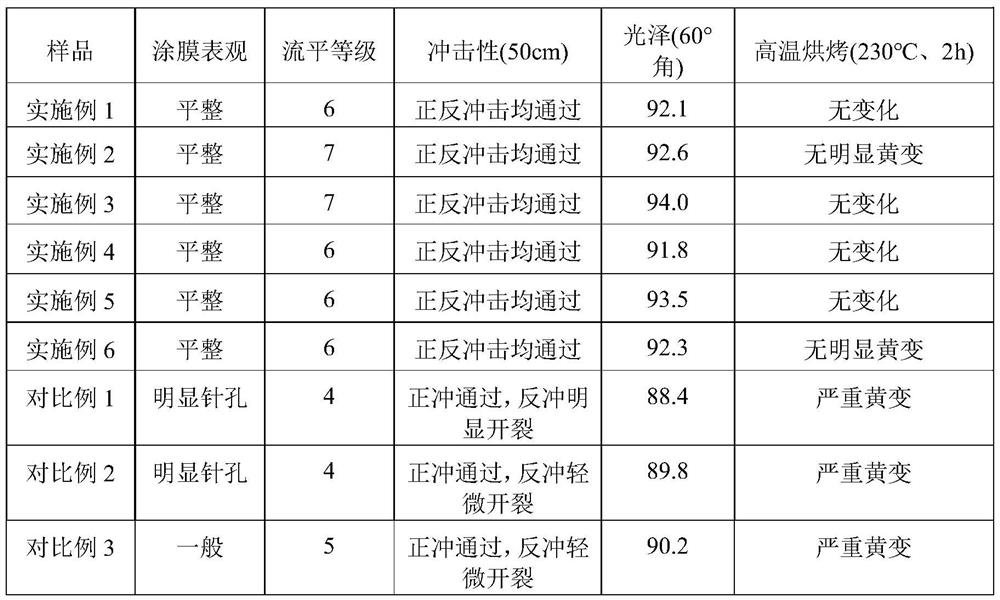

Embodiment 1

[0029] The yellowing-resistant β-hydroxyalkylamide curing agent described in this example uses a supported solid super-base catalyst Na / NaOH / Al 2 O 3 Prepare according to the following method: take a certain amount of nano-α-Al 2 O 3 (Particle size of 100-300nm) was added to the reactor, then high-purity argon (purity > 99%) was introduced into the reactor, and then the temperature was slowly raised to 350 ° C for high-temperature dehydration for 4 hours, and then cooled to 200 ° C. Add Metal sodium (controlling metal sodium and α-Al 2 O 3 The mass ratio is 1:5) After fully mixing, the temperature is increased to 500 °C for high temperature calcination for 12 h, and the supported solid super base catalyst Na / NaOH / Al is obtained. 2 O 3 .

[0030] The yellowing-resistant β-hydroxyalkylamide curing agent described in this embodiment is prepared according to the following method:

[0031](1) get diethanolamine 30mol, dimethyl adipate 60mol, add in the reactor 1 and fully mi...

Embodiment 2

[0038] The yellowing-resistant β-hydroxyalkylamide curing agent described in this example uses a supported solid super-base catalyst Na / NaOH / Al 2 O 3 Prepare according to the following method: take a certain amount of nano-α-Al 2 O 3 (Particle size of 100-300nm) was added to the reactor, and then high-purity argon (purity > 99%) was introduced into the reactor, and then the temperature was slowly raised to 400 ° C for high-temperature dehydration for 2 hours, and then cooled to 250 ° C. Add Metal sodium (controlling metal sodium and α-Al 2 O 3 The mass ratio of 1:10) was fully mixed, and the temperature was increased to 650 °C for high temperature calcination for 5 h to obtain a supported solid super base catalyst Na / NaOH / Al 2 O 3 .

[0039] The yellowing-resistant β-hydroxyalkylamide curing agent described in this embodiment is prepared according to the following method:

[0040] (1) get diethanolamine 65mol, dimethyl adipate 30mol, add in reactor 1 and mix fully, and ...

Embodiment 3

[0047] The yellowing-resistant β-hydroxyalkylamide curing agent described in this example uses a supported solid super-base catalyst Na / NaOH / Al 2 O 3 Prepare according to the following method: take a certain amount of nano-α-Al 2 O 3 (Particle size of 100-300nm) was added to the reactor, then high-purity argon gas (purity > 99%) was introduced into the reactor, and then the temperature was slowly raised to 380°C for high-temperature dehydration for 3h, and then cooled to 220°C, adding Metal sodium (controlling metal sodium and α-Al 2 O 3 The mass ratio is 1:8) After fully mixing, the temperature is increased to 580 °C for high temperature calcination for 8 h, and the supported solid super base catalyst Na / NaOH / Al is obtained. 2 O 3 .

[0048] The yellowing-resistant β-hydroxyalkylamide curing agent described in this embodiment is prepared according to the following method:

[0049] (1) get diethanolamine 45mol, dimethyl adipate 40mol, add in the reactor 1 and fully mix,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com