Physicochemical combination process based on recycling treatment of chlorella aging liquid

A combined process and aging solution technology, applied in the field of water treatment, can solve the problems of low utilization efficiency, bacterial pollution, high treatment cost, etc., and achieve the effect of improved effect and strong oxidation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

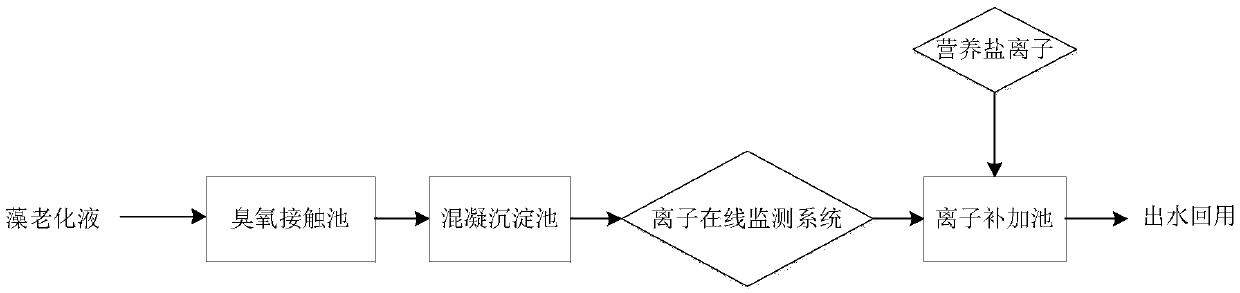

Image

Examples

Embodiment 1

[0025] Measure 500mL of chlorella aging solution provided by Cibai Enterprises, pump it into the ozone reaction tank, add 5mL of 30% hydrogen peroxide, set the ozone concentration at 6.5mg / L, and react for 30-60 minutes, the content of inhibitor fatty acids decreased 34%, pump the waste liquid into the coagulation sedimentation tank, adjust the pH to 6-6.5, and add 5 mg of composite flocculant (inorganic composite flocculant polymerized ferric magnesium sulfate and organic polymer flocculant polyacrylamide according to the ratio of 1:3 mass ratio compound), after mixing at a speed of 300r / min for 30s; stirring at a speed of 350r / min for 2min; stirring at a medium speed of 100r / min for 10min, stirring at a slow speed of 60r / min for 20min, and reprecipitating for 30min. A further reduction of 52%; the effluent enters the medium nutrient salt online monitoring and replenishment system, online monitoring of all anions and cations in the medium formula, it is measured that iron and ...

Embodiment 2

[0027] Measure 500mL of chlorella aging solution provided by Cibai Enterprises, pump it into the ozone reaction tank, add 5mL of 30% hydrogen peroxide, set the ozone concentration at 6.5mg / L, and react for 30-60 minutes, the content of inhibitor fatty acids decreased 34%, pump the waste liquid into the coagulation sedimentation tank, adjust the pH to 6-6.5, and add 5 mg of composite flocculant (inorganic composite flocculant polymerized ferric magnesium sulfate and organic polymer flocculant polyacrylamide according to the ratio of 1:4 mass ratio compound), after mixing at a speed of 300r / min for 30s; stirring at a speed of 350r / min for 2min; stirring at a medium speed of 100r / min for 10min, stirring at a slow speed of 60r / min for 20min, and reprecipitating for 30min. A further reduction of 57%; the effluent enters the medium nutrient salt online monitoring and replenishment system, online monitoring of all anions and cations in the medium formula, it is measured that iron and ...

Embodiment 3

[0029] Measure 500mL of chlorella aging solution provided by Cibai Enterprises, pump it into the ozone reaction tank, add 5mL of 30% hydrogen peroxide, set the ozone concentration at 6.5mg / L, and react for 30-60 minutes, the content of inhibitor fatty acids decreased 34%, pump the waste liquid into the coagulation sedimentation tank, adjust the pH to 6-6.5, and add 5 mg of composite flocculant (inorganic composite flocculant polymerized ferric magnesium sulfate and organic polymer flocculant polyacrylamide according to the ratio of 1:2 mass ratio compound), after mixing at a speed of 300r / min for 30s; stirring at a speed of 350r / min for 2min; stirring at a medium speed of 100r / min for 10min, stirring at a slow speed of 60r / min for 20min, and reprecipitating for 30min. A further reduction of 18%; the effluent enters the medium nutrient salt online monitoring and replenishment system, and all anions and cations in the medium formula are monitored online. It is measured that iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com