A glue amount detection device for concave space after glue dispensing

A detection device and space point technology, which is applied to the device, sorting, coating and other directions of coating liquid on the surface, can solve the problems such as the inability to digitize the detection accuracy, the detection accuracy rate is reduced, and the manual detection speed is slow. There is visual fatigue problem, simple structure, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

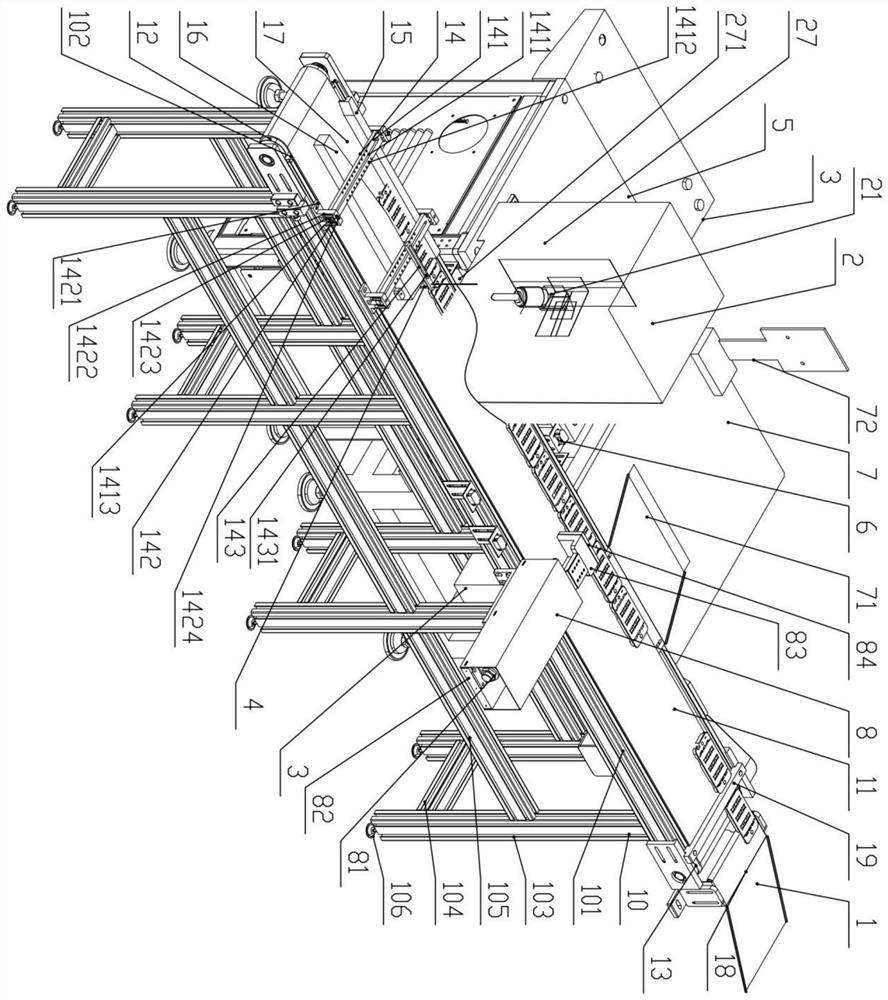

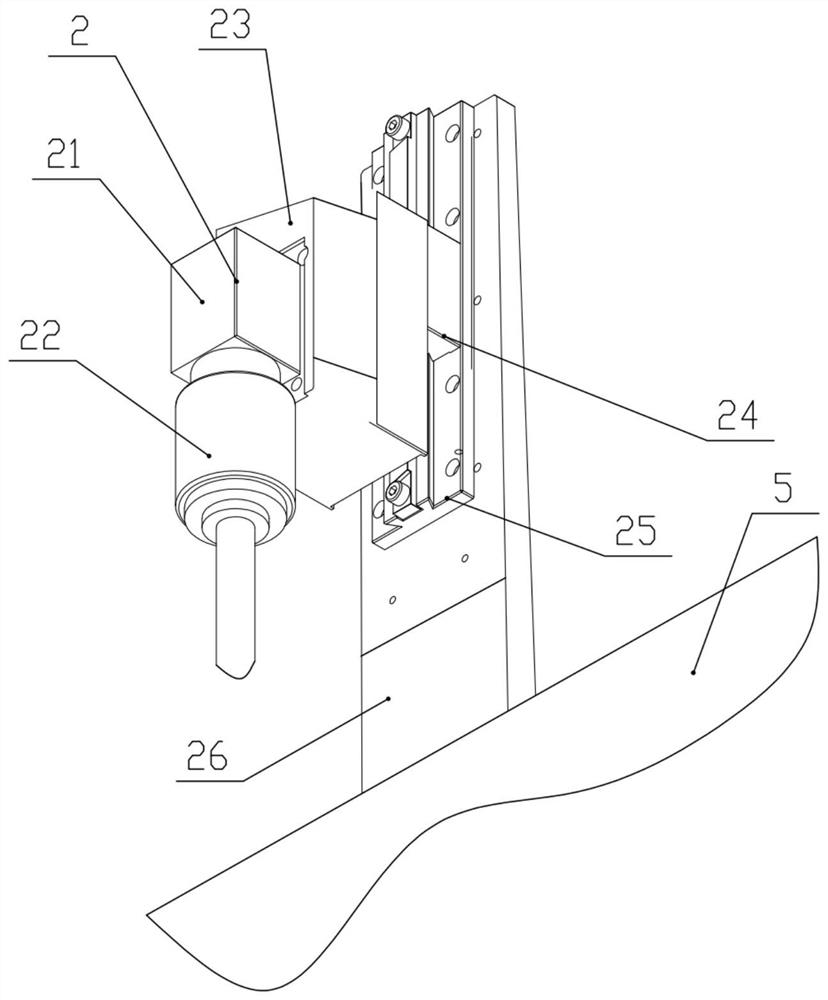

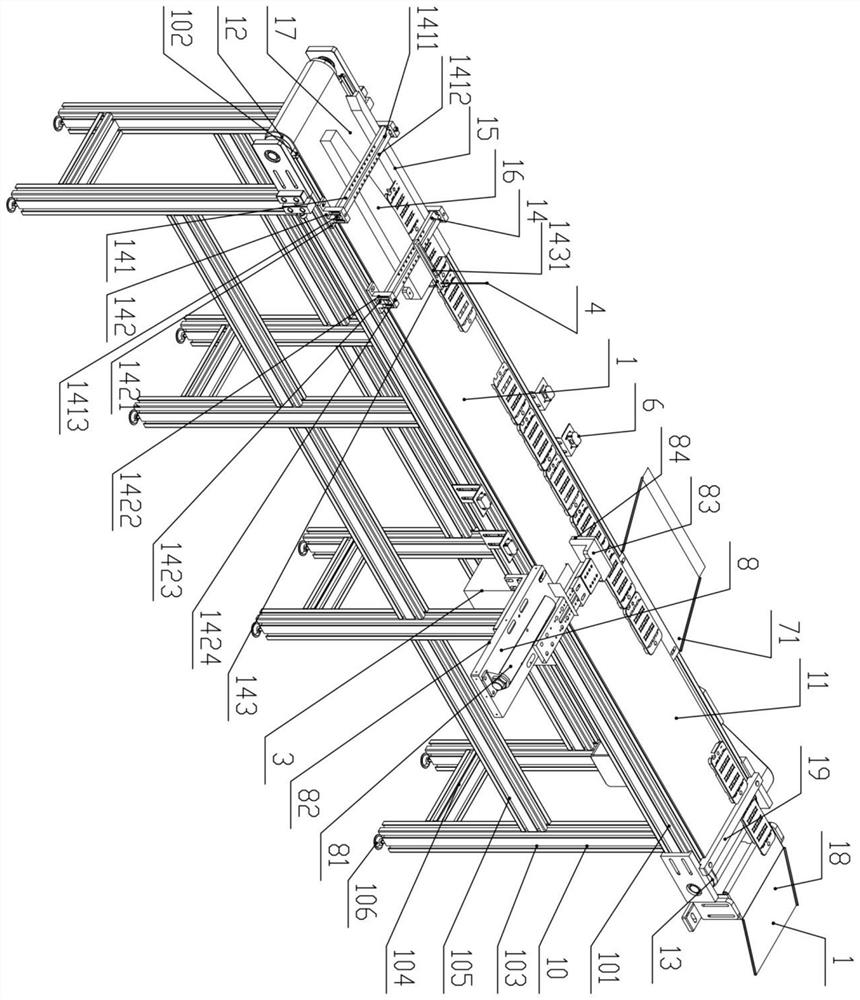

[0038] Figure 1 to Figure 7 Schematically shows a glue amount detection device for concave space after glue dispensing according to an embodiment of the present invention. As shown in the figure, the device includes a belt conveyor 1 and a detection assembly 2,

[0039] Belt conveyor 1 comprises frame 10, is provided with supporting plate 102 in the middle of the upper surface of frame 10, and frame 10 front end connects driven roller 12 and rear end connects driving roller 13, and driving roller 13 directly connects motor, driven roller 12, driving roller 13 And t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com