Horizontal glue valve glue wiping mechanism

A glue valve, horizontal technology, applied in the field of the horizontal glue valve wiping mechanism, can solve the problem of secondary pollution of the needle, and achieve the effect of avoiding secondary pollution and ensuring the cleanliness of the needle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

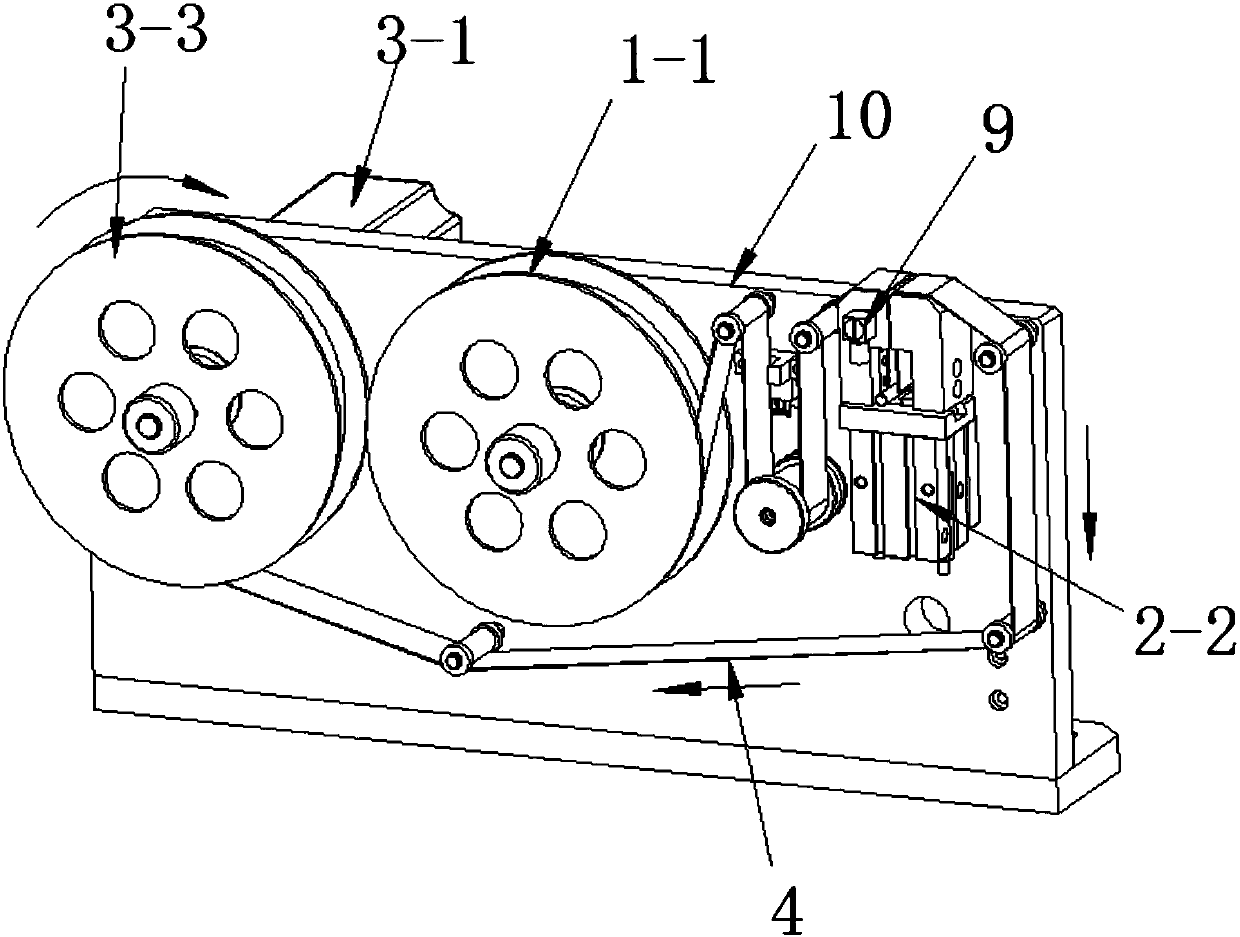

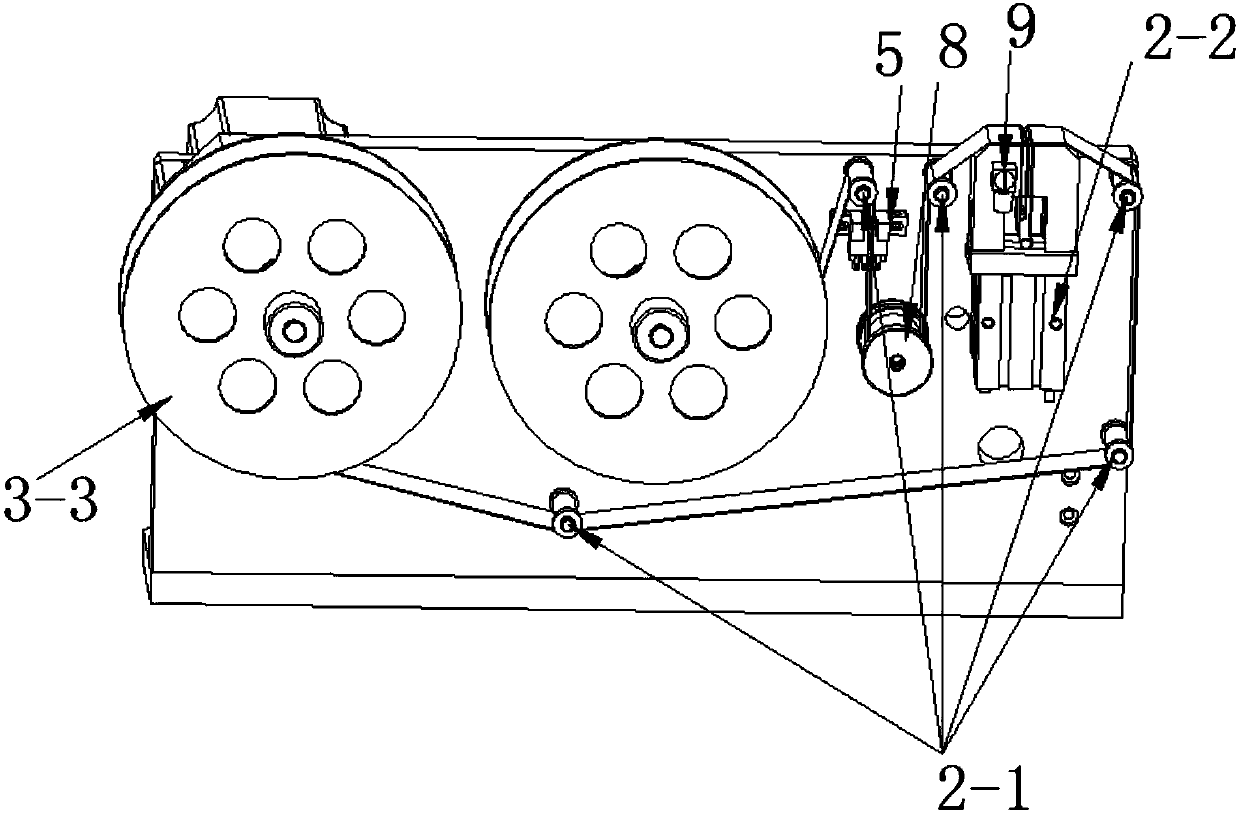

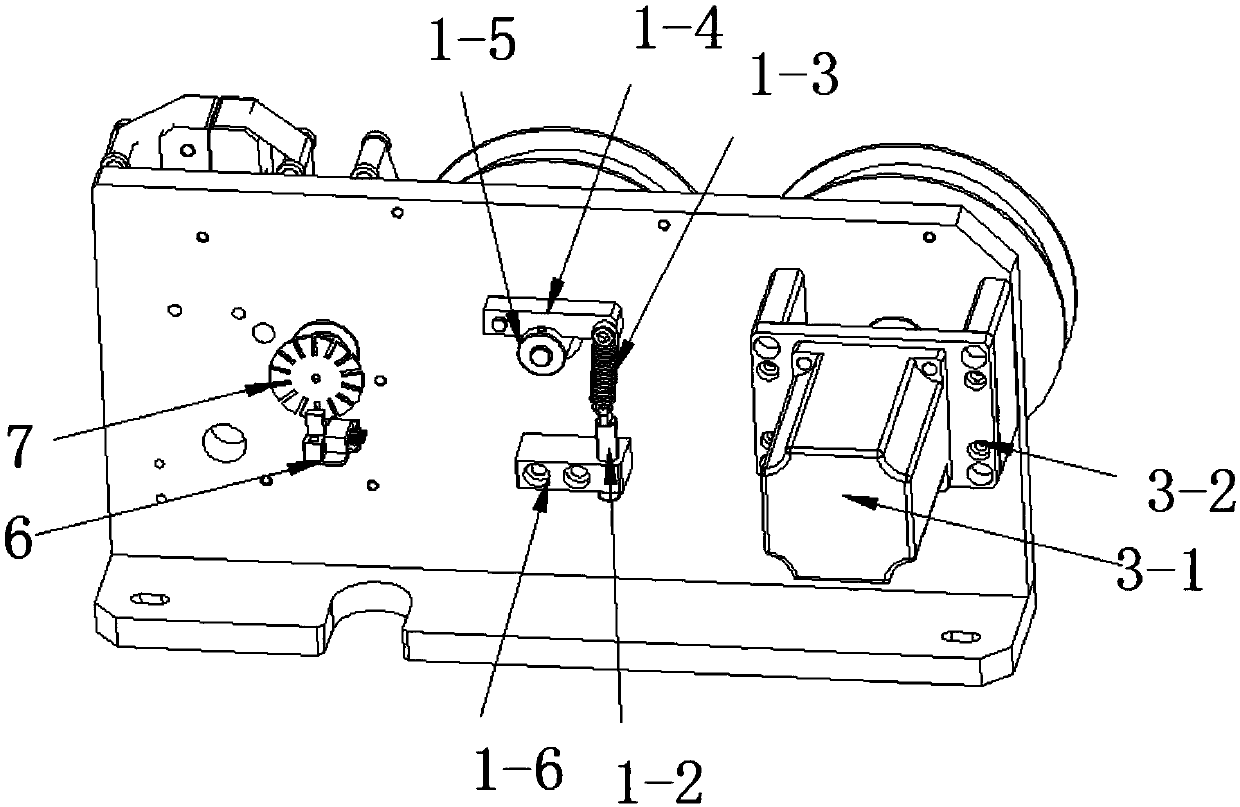

[0022] see as Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes a material discharging tension mechanism, a guide clamping mechanism and a material receiving mechanism; -2. The spring 1-3, the pressure block 1-4, the discharge installation disk shaft 1-5 and the adjustment screw bracket 1-6; the guide clamping mechanism is composed of a guide wheel 2-1, a finger clamp cylinder 2- 2. The receiving mechanism is composed of a motor 3-1, a shaft coupling 3-2, a receiving mounting plate 3-3, and a motor bracket 3-4; the tensioning mechanism, the guiding and clamping mechanism and the receiving The mechanisms are all arranged on the frame 10; wherein, the discharge installation disk 1-1 is screwed to the front of the frame 10 through the discharge installation disk shaft 1-5 on its back, and the discharge installation di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com