A kind of freeze-dried type instant tofu and preparation method thereof

A production method and convenient technology, applied in the fields of dairy products, cheese substitutes, food science, etc., can solve the problems of sticking to the wall, difficult equipment cleaning, and high requirements for production conditions, and achieve low solid content requirements and smooth and tender taste. , the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

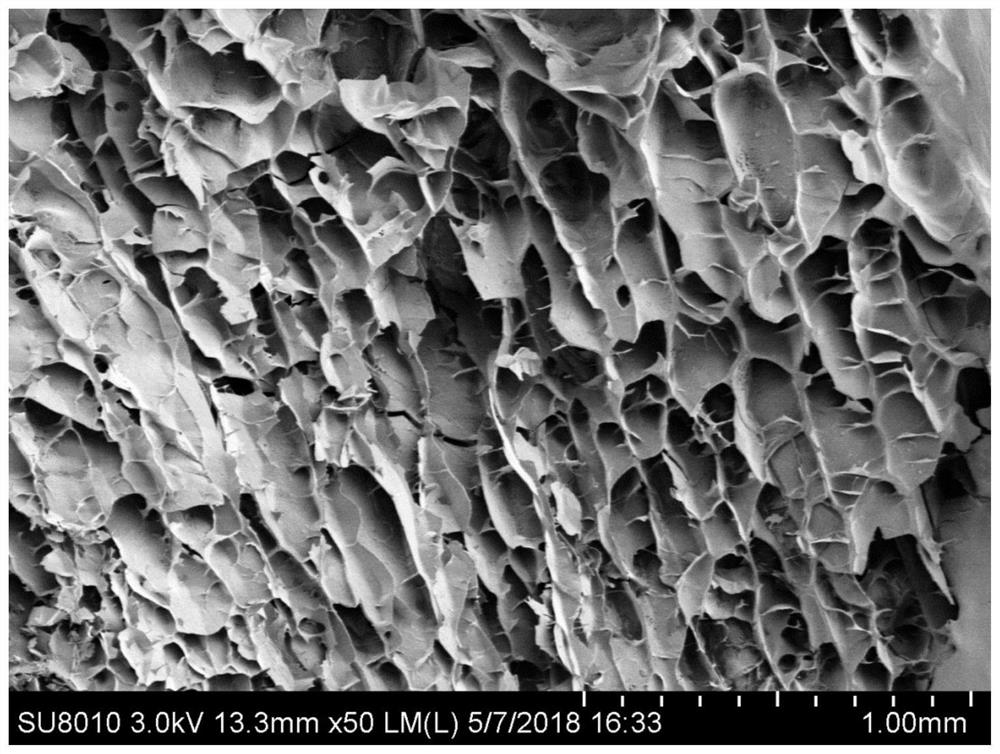

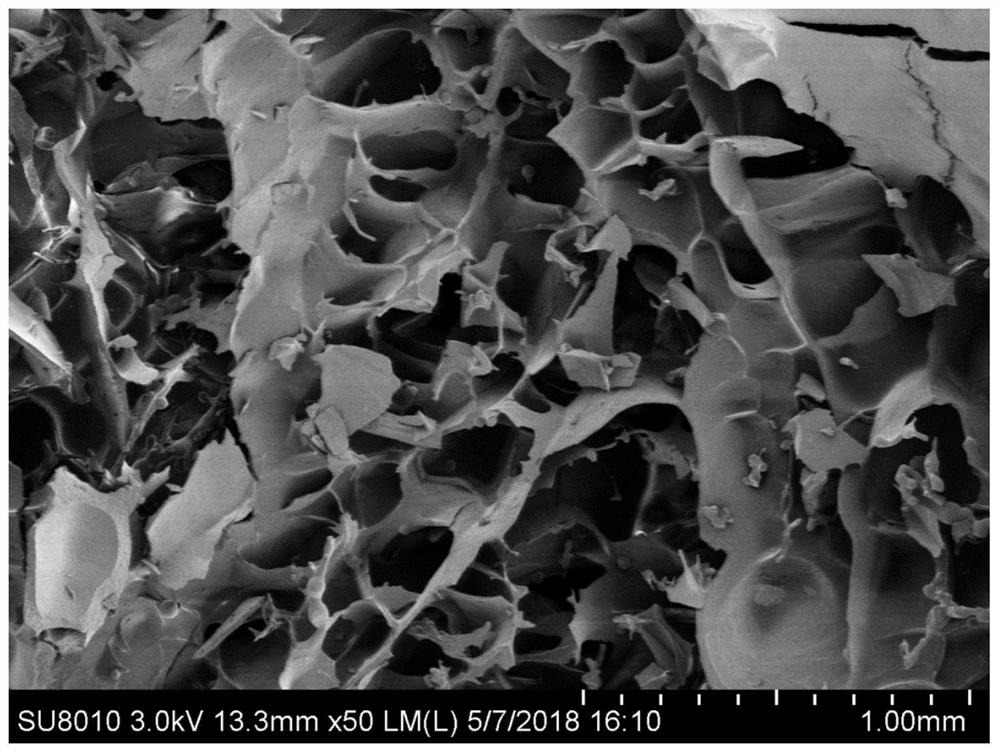

[0037] After the soybeans are completely soaked, they are beaten at a mass ratio of 1:7, and the antifoaming agent monoglycerol stearate is added to stand for 5 minutes, and the soybean dregs are removed to obtain soybean milk with a solid content of 9°Brix. Heat the soy milk, when the central temperature reaches 95°C, maintain it for 5 minutes. After boiling the pulp, add 1.6% gelatin aqueous solution of soybean milk quality (the consumption of water is 8 times of gelatin quality). After the soybean milk was cooled to about 45°C, 0.1% of the mass of soybean milk was added with transglutaminase (enzyme activity: 200 U / g), and then placed in a water bath at 45°C for 50 minutes for protein modification. After taking it out, add 0.3% D-glucono-δ-lactone in the mass of soybean milk, and put it in a water bath at 90°C for 30 minutes to make the soybean milk coagulate. The tofu obtained after heating and coagulating as described above was subjected to cooling treatment at 4°C. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com