Mariculture high-level pond

A technology of mariculture and high-level pools, applied in the field of aquaculture, can solve the problems of water not flowing, fish or shrimp escaping, and inducing bacteria, etc., to achieve the effects of avoiding losses, convenient water diversion, and increasing oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment the present invention is further described.

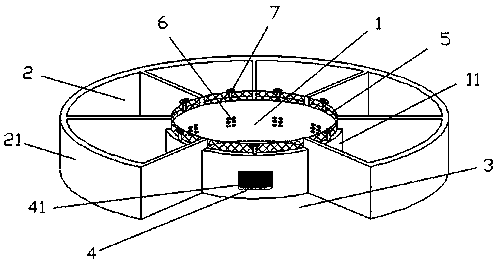

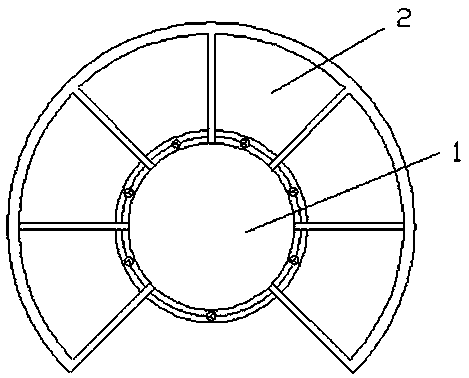

[0019] As shown in Figure 1-3, a seawater culture high level pond includes a snail culture area 1 and a shrimp culture area 2, the snail culture area 1 is a circular structure, and the shrimp culture area 2 consists of 6 shrimp culture areas Pond is formed, and with 1 diversion port 3, the snail culture area 1 is surrounded in the middle, and described diversion port 3 is provided with big water inlet 4, and big water inlet 4 is provided with gate 41.

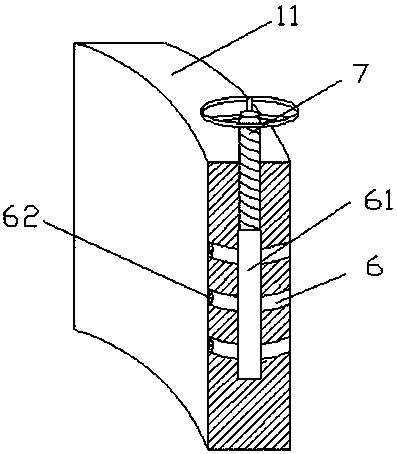

[0020] The base circumference 21 of the shrimp culture area 2 must be higher than the base circumference 11 of the snail culture area 1, and the base circumference 11 of the snail culture area is provided with gauze 5, and the gauze 5 needs to be higher than the base circumference 11 of the shrimp culture area 2. Around 21, the snail culture area 1 is provided with a small water inlet 6 communicating with the shrimp culture area 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com