Detection module and detection method for detecting offset degree of drill hole

A technology for detecting modules and degrees, applied in the direction of multi-layer circuit manufacturing, electrical components, printed circuit manufacturing, etc., can solve the problem of not necessarily accurately reflecting the whole batch of production boards, and achieve the effect of simple detection methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] This embodiment provides a method for manufacturing a circuit board, in which a detection module for detecting the degree of drilling deviation is provided during the production process, and a method for detecting the degree of drilling deviation by using the provided detection module.

[0031] The detection module made on the board in this embodiment is as follows:

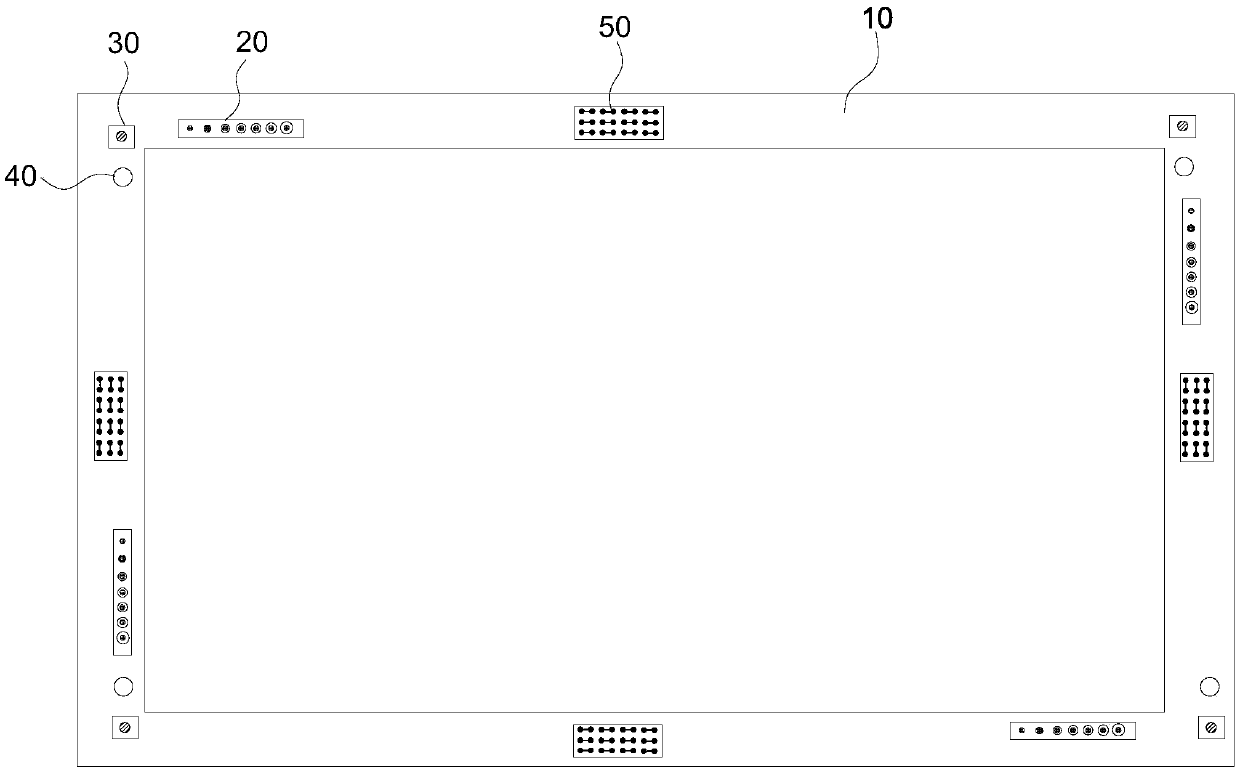

[0032] Such as figure 1 As shown, the detection module includes a total of four through hole detection units 20 respectively disposed on the four board edges 10 , and four laser drilling detection units disposed on the board edges 10 .

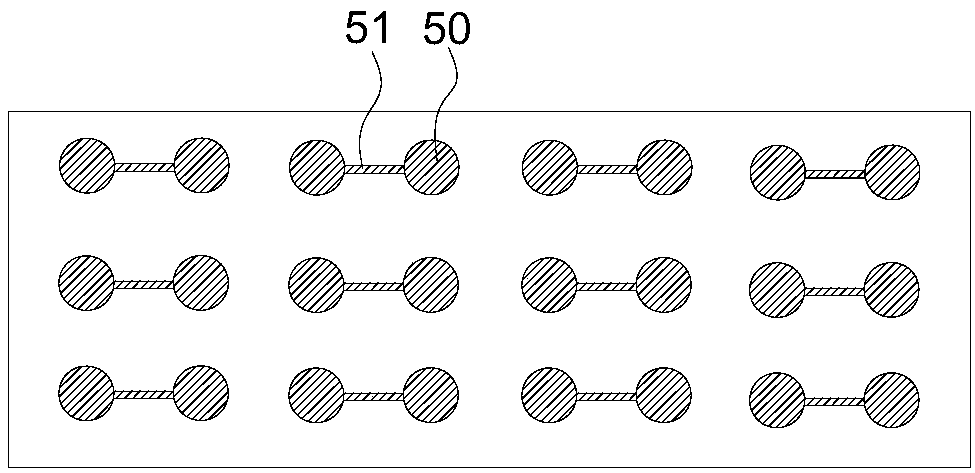

[0033] via detection unit 20, such as figure 2 As shown, it includes the copper-covered detection area 21 arranged on each circuit layer, the detection pattern arranged in each copper-covered detection area 21, the first metallized through hole 22 (aperture 1.15mm) and a row of six (aperture 1.15mm) mm) of the second metallized through hole 23; the detection pattern is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com