Evaporator and refrigeration system

A technology of evaporator and condenser, applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of increasing the height of the refrigeration system, large size of the air conditioner, reducing the size of the refrigeration system, etc., to improve the uniformity of heat exchange performance, close assembly relationship, and improve the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

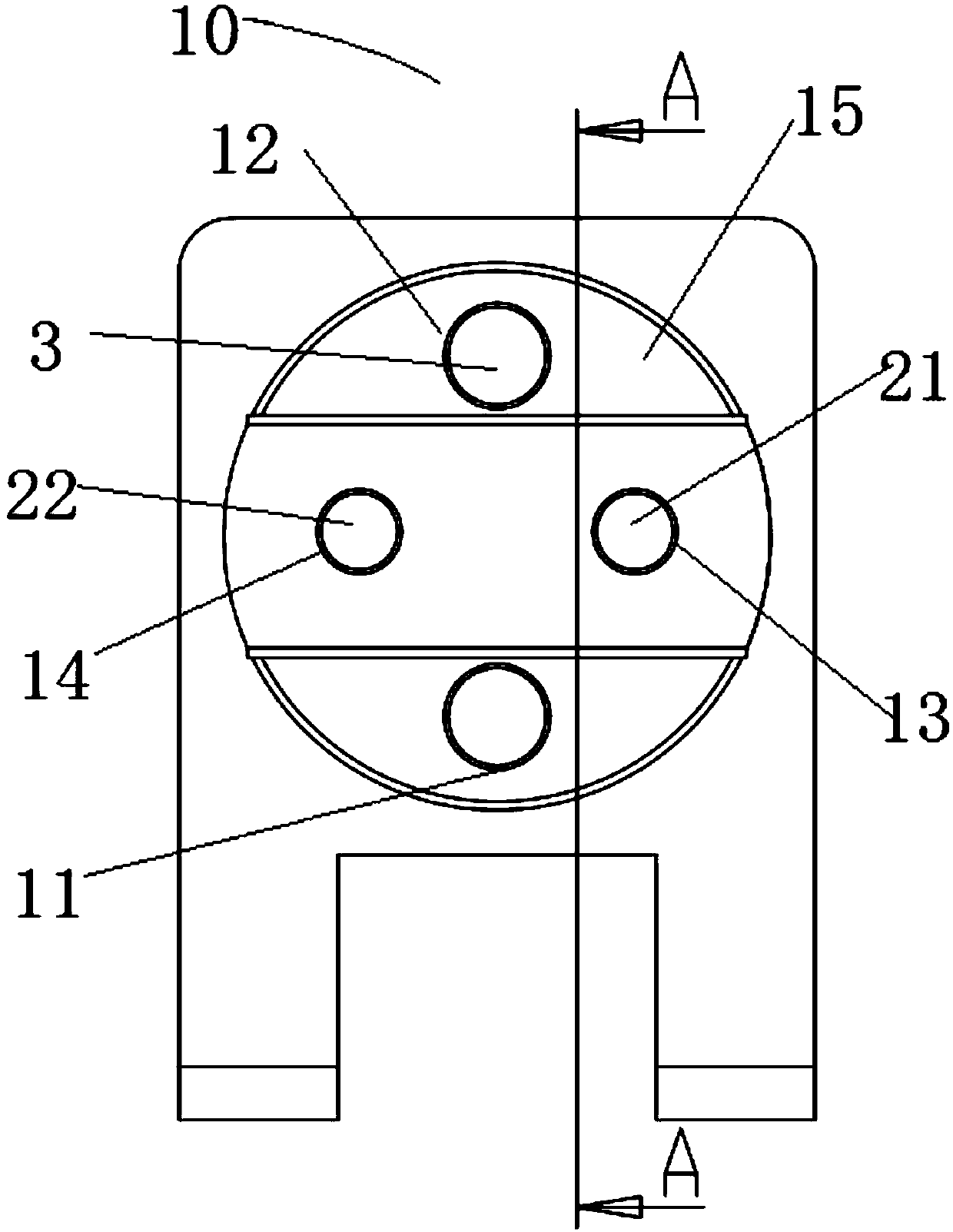

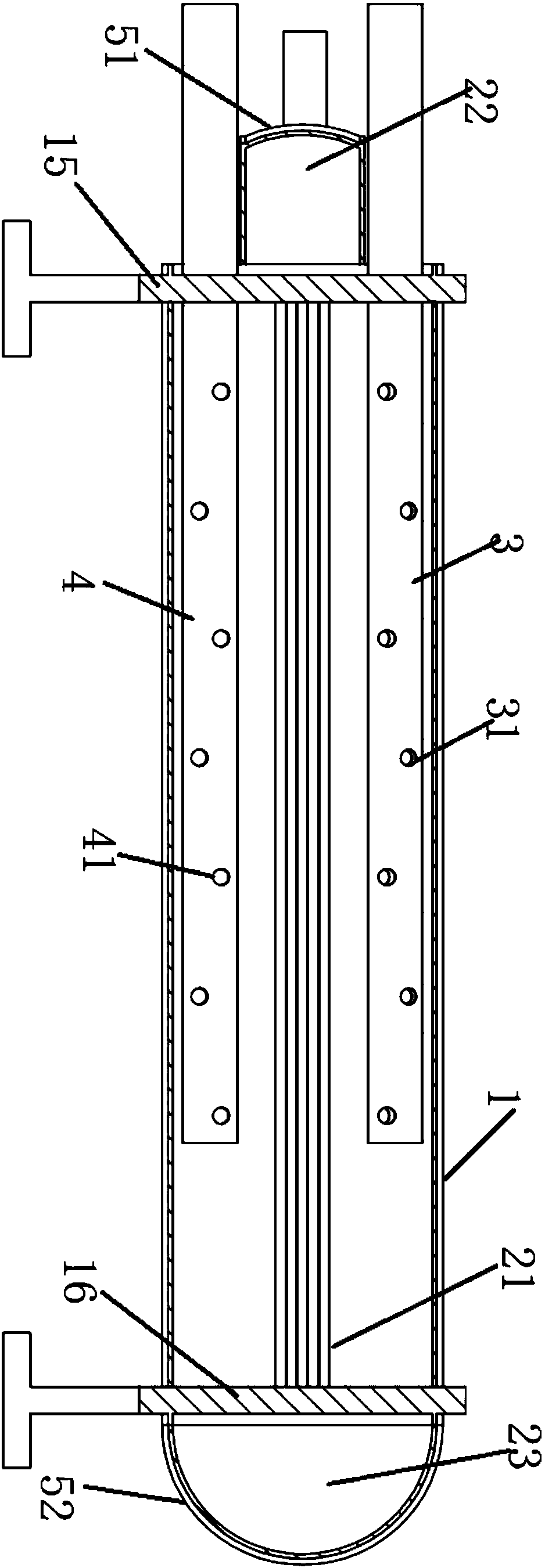

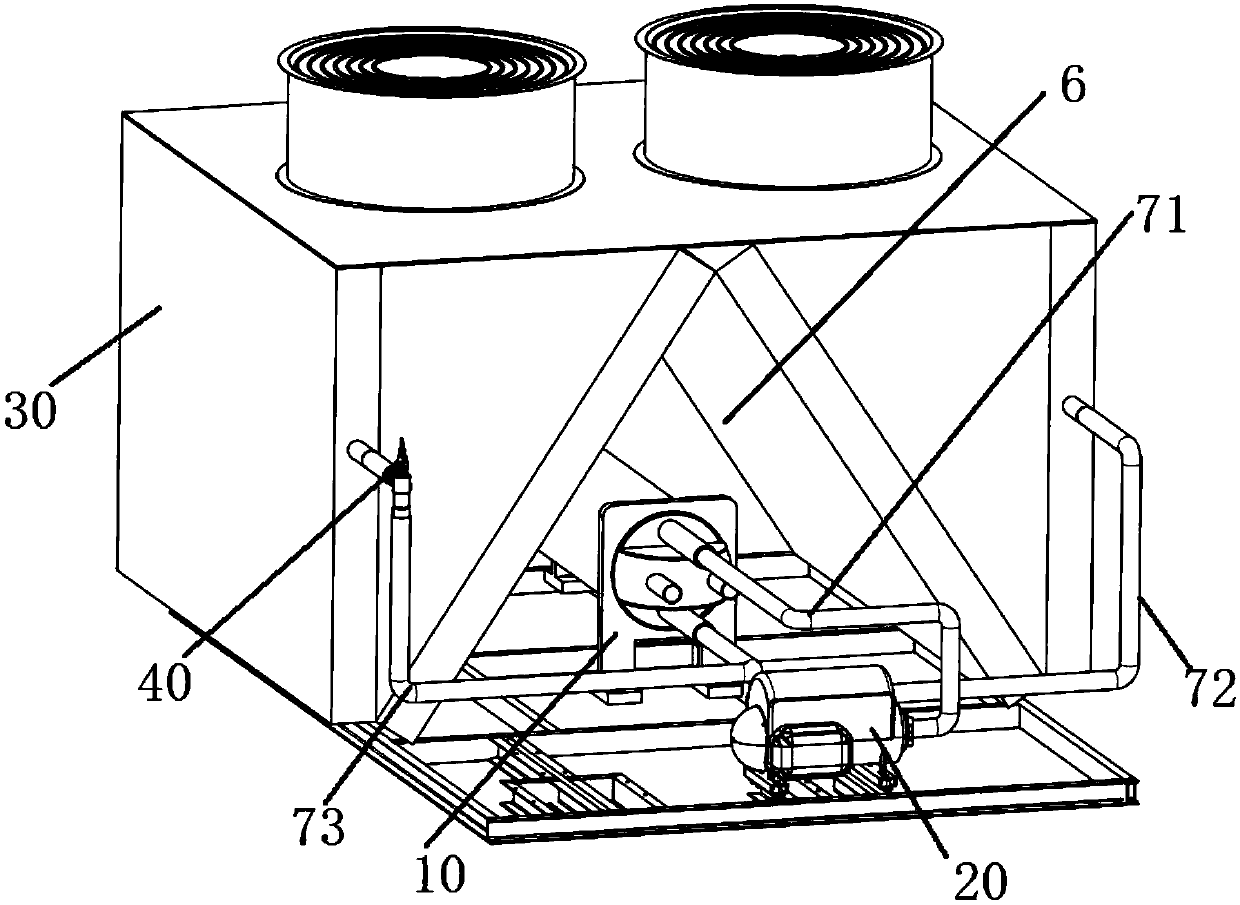

[0062] An evaporator is provided in this embodiment, such as figure 1 and figure 2 As shown, it includes a hollow cylinder 1, a heat exchange tube 2, an air collecting tube 3, and a distribution tube 4.

[0063] Wherein, the hollow cylinder 1 is arranged horizontally, and includes a body with a hollow inner cavity, and a first end plate 15 and a second end plate 16 installed on openings at both ends of the body. The first end plate 15 is provided with a first liquid inlet 11 , a first gas outlet 12 , a second liquid inlet 13 and a second liquid outlet 14 . The first gas outlet 12 is located above the first liquid inlet 11; along the vertical direction, the second liquid inlet 13 and the second liquid outlet 14 are located between the first gas outlet 12 and the first liquid inlet 11

[0064] The first end plate 15 is also provided with a first cover 51, for example, the first cover 51 is an arc-shaped plate, the first cover 51 is located between the first liquid inlet 11 an...

Embodiment 2

[0072] This embodiment provides an evaporator, which is different from the evaporator 10 provided in Embodiment 1 in that:

[0073] The suction port 31 on the gas collecting pipe 3 is not only set on the top of the gas collecting pipe 3, but also can be set on any wall surface of the gas collecting pipe 3. During the gas rising process, the effect of gas-liquid separation can still be achieved under the weight of the liquid itself. .

[0074] As a first alternative embodiment, the number of air inlets 31 can also be one, two, three, four, five, etc., the more the number of air inlets 31 is set, the cooling can be timely The gas formed by the refrigerant is pumped into the gas collecting pipe 3; the smaller the number of suction ports 31 is set, the time required for the gas formed by the refrigerant to be pumped into the gas collecting pipe 3 is relatively long, and the specific number of settings depends on the actual use .

[0075] As a further alternative embodiment, the fi...

Embodiment 3

[0077] This embodiment provides an evaporator, which is different from the evaporator 10 provided in Embodiment 1 or Embodiment 2 in that:

[0078] The location of the opening of the liquid distribution port 41 is different, and the opening direction of the liquid distribution port 41 may not face the side of the heat exchange tube 2; the adjacent liquid distribution ports 41 may also be located at the same height, or arranged in a disorderly manner. The distribution pipe 4 is provided with a liquid dispensing port 41 , so that the refrigerant can be sprayed into the inner cavity of the cylinder body 1 to exchange heat with the solution in the heat exchange pipe 2 .

[0079] As a first alternative embodiment, the number of liquid distribution ports can be one, two, three, four, five, etc., only need to inject the refrigerant in the distribution pipe 4 into the cylinder 1 in the cavity. The specific number of settings depends on the actual usage.

[0080] As a further alterna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com