Telescopic overhung support and mounting method thereof

A cantilever and oblique support technology, applied in pillars, erection/assembly of bridges, processing of building materials, etc., can solve the problems of high scaffolding cost, high height, and troublesome construction of supporting formwork, so as to achieve low construction cost and reduce construction cost. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

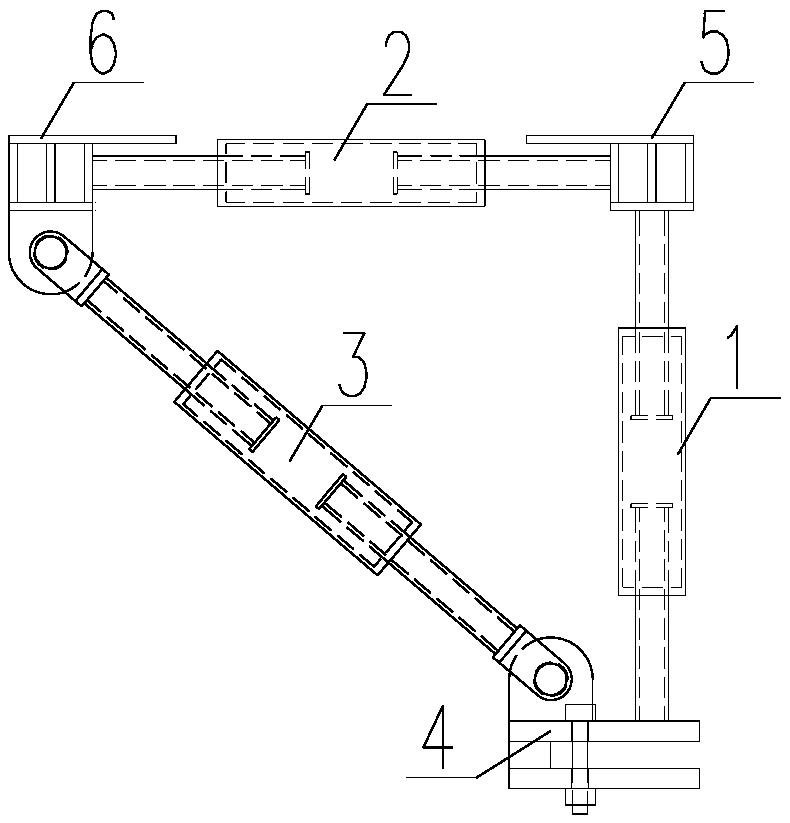

[0036] Embodiment 1: as Figure 1-8 As shown, a telescopic cantilever support includes a vertical support 1, a horizontal support 2, an oblique support 3, a lower support 4, an upper support 5 and a cantilever support 6;

[0037] The vertical support includes a screw 11, a screw end plate 12, a sleeve 13 and a sleeve end plate 14 containing internal threads, wherein the two screw rods have opposite thread directions. In and out at the same time, the screw end plate can prevent the screw from falling off;

[0038] The horizontal support 2 includes a screw 21, a screw end plate 22, a sleeve 23 and a sleeve end plate 24 containing internal threads, wherein the two screw rods have opposite thread directions. In and out at the same time, the screw end plate can prevent the screw from falling off;

[0039] The oblique support 3 consists of seven parts: screw rod 31, screw end plate 32, sleeve 33, sleeve end plate 34 with internal thread, connecting plate 35, connecting lug plate 3...

Embodiment 2

[0044] Embodiment 2: This embodiment also includes a method for installing a telescopic cantilevered support, including the following steps:

[0045] Step 1: According to the height of the steel beam 8 (see Figure 10 ) or steel box girder 7 (see Figure 9 ) height and cantilever distance to choose the appropriate cantilever support;

[0046] Step 2: Set the distance between cantilevered supports after calculation and analysis;

[0047] Step 3: Adjust the overhang value of the overhang support according to the distance of the overhang plate, and fix the overhang distance on the ground;

[0048] Step 4: Set up a simple scaffold or use a climbing car to install a cantilever support;

[0049] Step 5: install formwork 9 or reinforced truss floor deck 9 on the upper surface of support upper support 5 and cantilever support 6 (see Figure 9 , 10 );

[0050] Step 6: After the concrete pouring is completed, remove the support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com