Water circulation rotational flow polishing machine facilitating replacing of abrasive materials

A convenient replacement and water circulation technology, applied in grinding/polishing equipment, grinding/polishing safety devices, grinders, etc., can solve the problems of troublesome abrasive replacement, labor-intensive, waste, etc., to achieve convenient abrasive replacement, convenient cleaning of workpieces, The effect of speeding up the rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

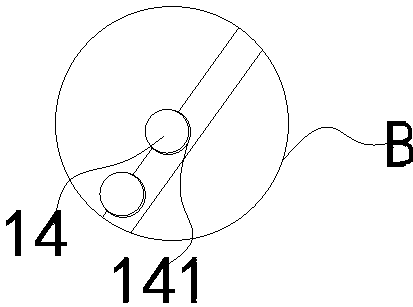

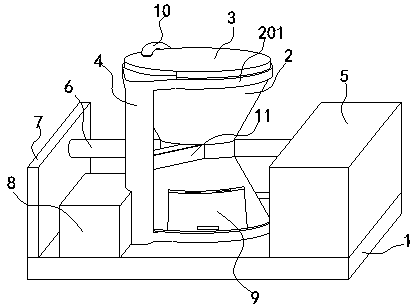

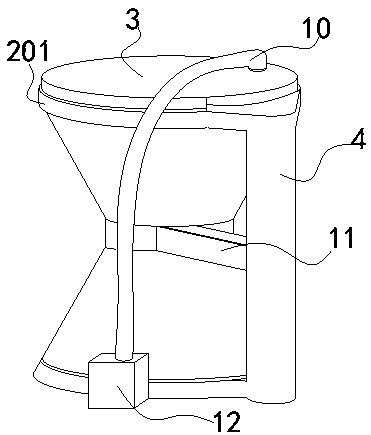

[0028] see Figures 1 to 8 , a schematic diagram of the plane structure and a schematic diagram of the three-dimensional structure of a water circulation swirl finishing machine that facilitates the replacement of abrasives.

[0029] A water circulation swirling finishing machine for convenient replacement of abrasives, comprising a base 1 and a finishing machine 2, a rotating machine 5 is fixedly connected to the upper right side of the base 1, and a rotating rod 6 is movably connected to the left side of the rotating machine 5, and the rotating rod 6 They are respectively fixedly connected to both sides of the finishing machine 2, the left end of the rotating rod 6 is movably connected to a support plate 7, the upper end of the finishing machine 2 is fixedly installed with a top cover 3, and the top cover 3 is fixedly connected to a water pipe 10, and the finishing machine 2 An arc casing 201 is fixedly installed on the top edge of the arc casing 201, and the left side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com