Straw feed production apparatus

A technology for making equipment and straw feed, which is applied in the direction of feed, food science, application, etc., and can solve the problems of decomposition and low digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

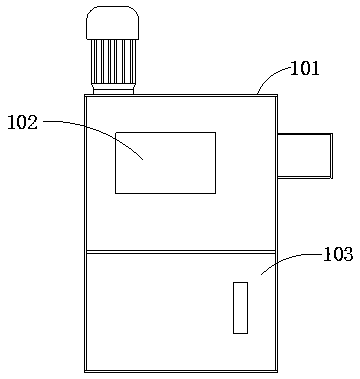

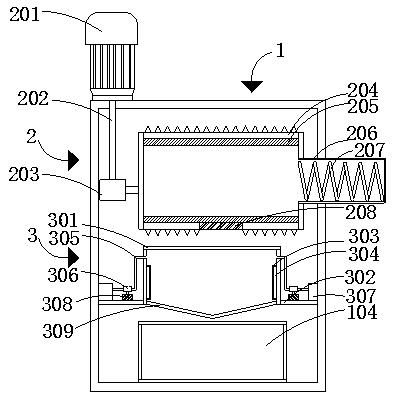

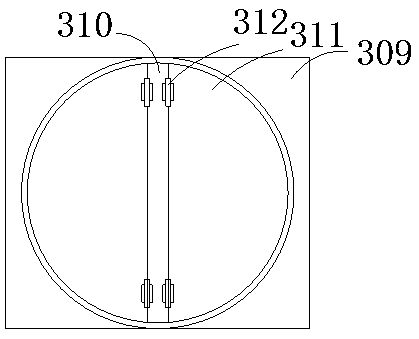

[0018] Such as Figure 1-3 As shown, the present invention provides a technical solution: a straw feed production device, including a production machine frame 1, a crushing mechanism 2 and a reaction mechanism 3, and the production machine frame 1 includes a body 101, a control panel 102, a door 103 and a collection box 104 , the control panel 102 is fixedly connected to the top of the body 101 surface by fixing bolts, the door 103 is hinged to the bottom of the machine frame 1 surface, the collection box 104 is located at the bottom of the inner cavity of the machine frame 1, and the crushing mechanism 2 includes a rotating motor 201, a rotating shaft 202, transmission 203, ball mill 209, feeding port 206 and feeding screw 207, the rotating motor 201 is fixedly connected to the top side of the frame 1 of the manufacturing machine through fixing bolts, and the rotating shaft 202 passes through the frame 1 of the manufacturing machine and is fixed to the bottom of the rotating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com