Flat tea shaping device

A shaping device and tea technology, which is applied in tea processing before extraction, etc., can solve the problems of poor control of uniformity, large quantity of inferior tea leaves, and small output of high-quality tea, so as to achieve standardization, less manual participation, and high quality. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

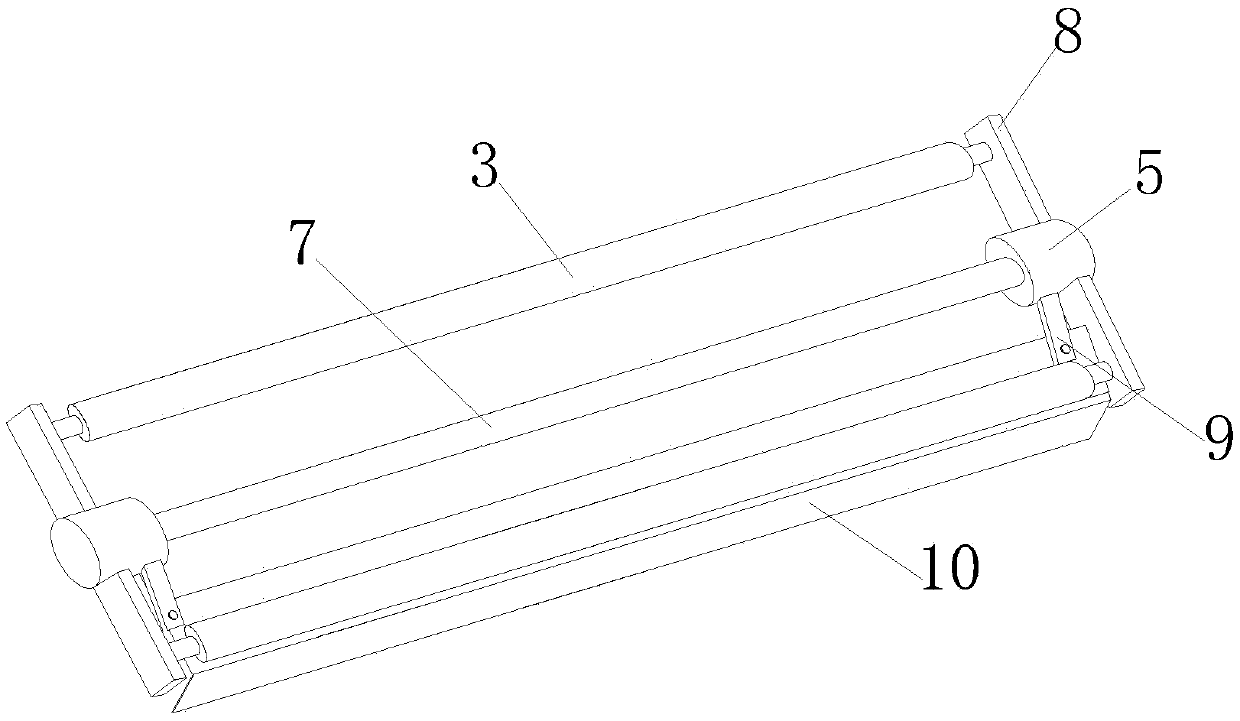

[0025] combine figure 1 , a flat tea shaping device proposed by the present invention includes: a frame 1 and a shaping unit.

[0026] Combined with 1 and 2, the frame 1 is provided with a plurality of arc-shaped slots 4 that abut against each other along its length direction, and the length direction of the arc-shaped slots 4 is consistent with the width direction of the frame 1; The shaping unit includes the same number of shaping mechanisms as the arc grooves 4, one of which is driven by the motor 2, and the shaping mechanisms are connected by transmission.

[0027] combine image 3 , the shaping mechanism includes two shaft sleeves 5, a rotating shaft 7, a shaping roller 3 and a transfer plate 10; the two shaft sleeves 5 are respectively rotatably connected to both sides of the frame 1, and the connecting line between the centers of the two shaft sleeves 5 Parallel to the width direction of the frame 1, the two ends of the rotating shaft 7 are respectively sleeved in two...

Embodiment 2

[0039] The transfer plate 10 is a core component of the device, which not only lifts the tea leaves at the bottom of the curved groove 4 to the top of the curved groove 4, but also allows the tea leaves to fall into another curved groove 4 in time. Therefore, relative to Embodiment 1, this embodiment also discloses the structure of the transfer plate 10 . Specifically, the transfer plate 10 is formed by bending a flat plate twice, and includes a first connection section, a second connection section and a third connection section, and the first connection section is attached to the support arm 8 Above, the second connection section is connected to the first connection section at an angle of α°, and the third connection section is connected to the second connection section at an angle of β°, 160≤α≤170, 160≤β≤ 170.

[0040] The transfer plate 10 forms a three-section structure through the bending action on both sides, and the space between the third connecting section and the in...

Embodiment 3

[0043] The difference between this embodiment and the above-mentioned embodiment is that this embodiment also discloses the following technical features: two supporting arms 8 are formed on the outer circumference of the bushing 5, and the shaping Roller 3 , two shaping rollers 3 are distributed mirror-symmetrically with respect to the axis of the rotating shaft 7 .

[0044] The shaping roller 3 is a component used for shaping the tea leaves, and the frequency at which the shaping roller 3 acts on the tea leaves determines the number of arc-shaped grooves 4 that the device needs to arrange. In this embodiment, the shaping rollers 3 are arranged on both sides of the support arm 8 . Through the synergistic effect of the two shaping rollers 3 , compared with one shaping roller 3 , the shaping efficiency and effect are obviously improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com