Production method of flat black tea

A production method and technology of flat black tea, which is applied in the field of tea processing, can solve the problems of bitterness and astringency of finished tea products, lack of taste and aroma, and affect the quality of black tea, etc., to achieve increased taste and aroma, flat and straight strands, and obvious honey aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

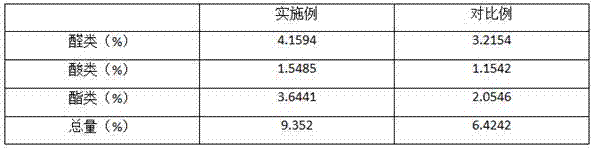

Examples

Embodiment

[0029] This scheme provides a kind of production method of flat black tea, comprises the following steps:

[0030] S1. Tea selection: select green tea with a single bud or one bud and one leaf, the length of the buds and leaves is 2.5~3cm;

[0031] S2. Withering: put the plucked tea greens into a constant temperature hot air withering tank for withering, the thickness of the tea greens is 5-6cm, the withering temperature is 26-30°C, and the withering time is 7h;

[0032] S3. Kneading: Put the withered tea leaves into the kneading machine. When kneading, the room temperature is 20~24°C, the humidity is 86%, and the kneading time is 35 minutes. 10 minutes → Knead for 10 minutes without pressure → Knead with light pressure for 5 minutes → Knead for 5 minutes without pressure, the control of the light pressure is: use the pressure plate to compress the thickness of the tea leaves to 4 / 5 of the original thickness;

[0033] S4, deblocking and sub-sieving: use a tea deblocking machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com