Lightning-proof ground structure for high-rise building and construction method

A lightning protection grounding, high-rise building technology, applied in the direction of connecting contact materials, etc., can solve the problems of slow construction speed, high copper cost, high cost and high cost, and achieve the effect of simple production and installation, avoiding welding and easy bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

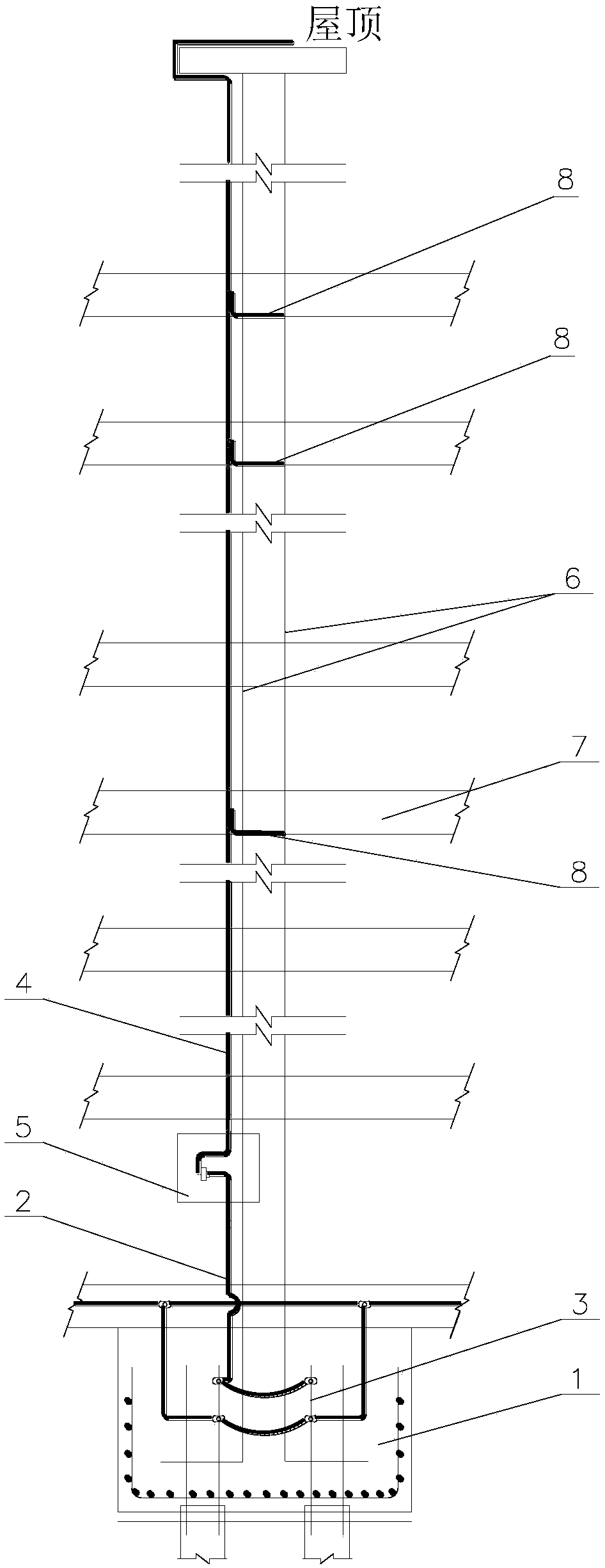

[0026] A building with 63 floors.

[0027] A construction method for a lightning protection grounding structure of a high-rise building, comprising the following steps:

[0028] 1) The copper sheet conductive belt is made of copper sheet welding. Firstly, the copper sheet conductive belt and the steel bar are welded to form a grounding body at the base layer and the upper layers to ensure that the current is stably transmitted to the ground and poured layer by layer.

[0029] 2) Preparation before conversion: the aluminum sheet conductive belt is made of aluminum sheet welding, the aluminum segment formed by welding multiple aluminum sheets, and the insulator is wrapped on the outside, and the insulator is baked with a torch, so that the insulator shrinks and sticks tightly to the aluminum segment superior.

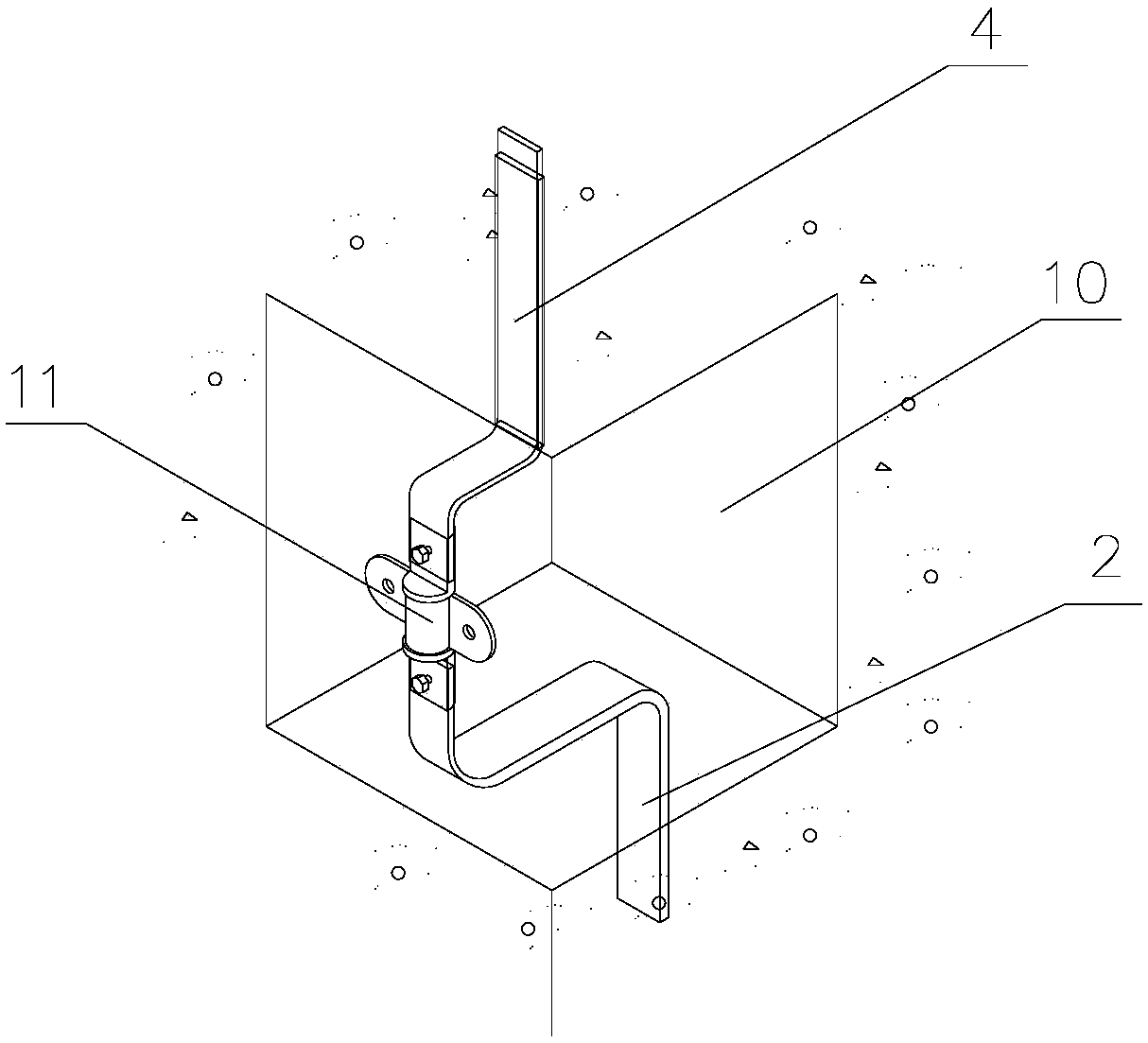

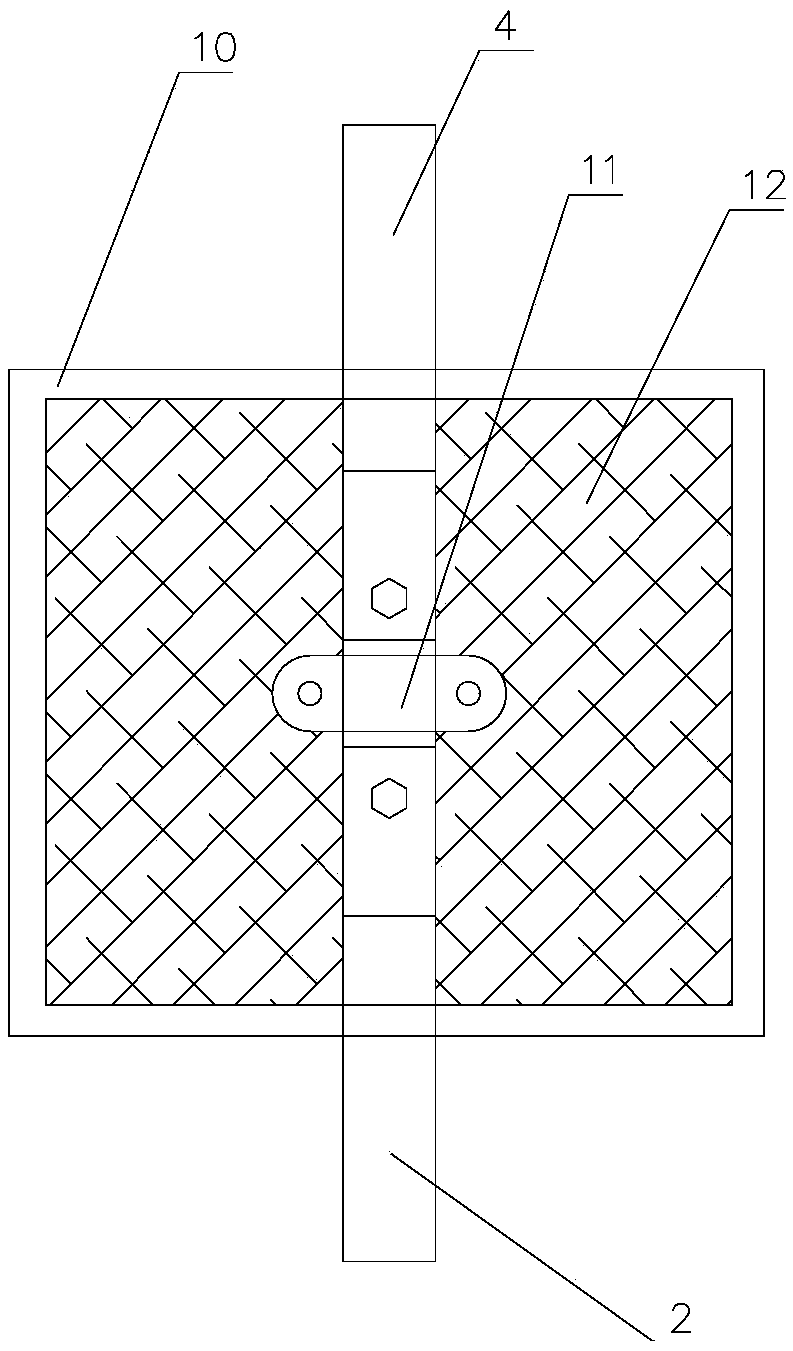

[0030] 3) Conversion of copper conductive strips and aluminum conductive strips: keep the copper conductive strips as vertical as possible, and try not to cause slopes d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com